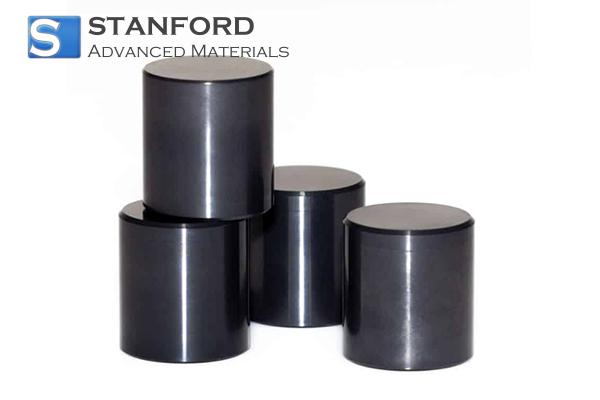

Silicon Nitride Ring Descriptions:

Silicon Nitride is an all-around talent in the technical ceramics area. With its great strength and fracture toughness, good thermal shock resistance, and excellent wear and impact resistance, silicon nitride is ideal for a wide range of applications. Its low density and great strength also enable the optimal implementation of lightweight structures.

Silicon Nitride Ceramic is an inorganic material ceramic that does not shrink during sintering. There are five different methods to produce Silicon Nitride including SRBSN, GPSN, HPSN, HIP-SN, and RBSN, making the application and working material different slightly.

Silicon Nitride Ring Specifications:

|

Item

|

Unit

|

Typical Values

|

|

Density

|

g/cm3

|

3.22

|

|

Physical Properties

|

|

Hardness

|

-

|

HRA90

|

|

Vickers Hardness (Hv50)

|

HV0.5

|

>1550

|

|

Modulus of Elasticity

|

Gpa

|

290

|

|

Flexural Strength

|

MPa

|

>600

|

|

Compressive Strength

|

MPa

|

2500

|

|

Fracture Toughness, KIc

|

MPa•m1/2

|

>6.0

|

|

The Thermodynamic Property

|

|

Max. Use Temperature

|

ºC

|

1200

|

|

Thermal Conductivity

|

W/m•k

|

15-20

|

|

Thermal Expansion Coefficient

|

10-6/ ºC

|

>3.1

|

|

Thermal Shock Resistance

|

ΔT ºC

|

500

|

|

Specific Heat Capacity

|

KJ/kg.k

|

700

|

|

Electrical Property

|

|

Volume Resistivity at 20 ºC

|

Ω•cm

|

1.0x1012

|

Silicon Nitride Ring Features:

-High strength over a wide temperature range

-High fracture toughness

-High hardness

-Outstanding wear resistance

-Low thermal expansion and high thermal conductivity

-Good thermal shock resistance

-Good resistance to chemical and oxidation

Silicon Nitride Ring Applications:

1. Bearings: Silicon nitride rings are often used in ceramic bearings, including both ball and roller bearings. They offer high hardness, low density, and excellent resistance to wear and corrosion, making them ideal for high-speed, high-temperature, and corrosive environments.

2. Seals: Used as sealing rings in pumps and compressors, especially in industries dealing with aggressive chemicals and high temperatures. Silicon nitride's chemical inertness and thermal stability ensure long-lasting performance.

3. Aerospace: Employed in various aerospace components where high strength-to-weight ratio and thermal stability are crucial. Silicon nitride rings can withstand extreme temperatures and reduce the overall weight of aerospace assemblies.

4. Automotive: Utilized in high-performance engine components, such as turbocharger rotors and cam followers, where their low weight and high thermal resistance improve efficiency and longevity.

5. Machine Tooling: Silicon nitride rings are used in machine tool spindles and other high-precision, high-speed applications. Their rigidity, low thermal expansion, and wear resistance enhance the performance and accuracy of machine tools.

6. Semiconductor Manufacturing: Applied in semiconductor processing equipment, where their high purity, thermal stability, and resistance to wear and corrosion are essential for maintaining clean and stable manufacturing conditions.

7. Medical Devices: Used in medical instruments and implants due to their biocompatibility, wear resistance, and ability to withstand sterilization processes.

8. Energy Sector: Silicon nitride rings are employed in high-temperature and high-pressure applications in the energy industry, including gas turbines and power generation equipment.

9. Chemical Processing: Utilized in valves, pumps, and other components exposed to corrosive chemicals, leveraging silicon nitride's chemical resistance and mechanical strength.

10. Optical Devices: Used in high-precision optical devices and instruments where their stability, low thermal expansion, and durability are critical.

Silicon Nitride Ring FAQs

- How are Silicon Nitride Rings manufactured?

Silicon Nitride Rings are typically manufactured using powder processing techniques such as hot pressing, reaction bonding, or sintering. These methods involve compacting silicon nitride powder into the desired shape and then sintering it at high temperatures to form a dense and durable ceramic material.

- What are the different types of Silicon Nitride Rings?

Silicon Nitride Rings can vary in size, shape, and composition depending on their intended application.

- Are Silicon Nitride Rings compatible with other materials?

Yes, Silicon Nitride Rings are compatible with a wide range of materials commonly used in industrial applications, including metals, plastics, and other ceramics. They can be used in combination with these materials to create hybrid components or assemblies with enhanced performance characteristics.

Silicon Nitride Ring Packaging:

SAM’s Silicon Nitride Ring is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano