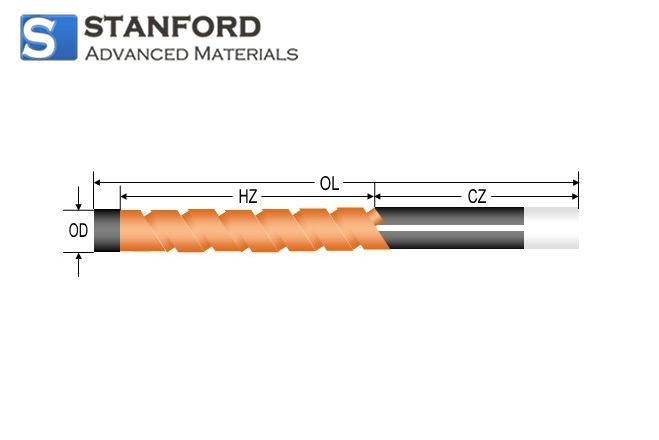

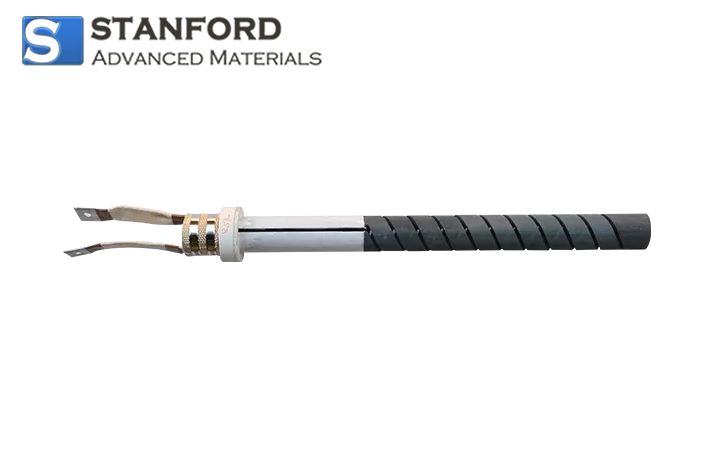

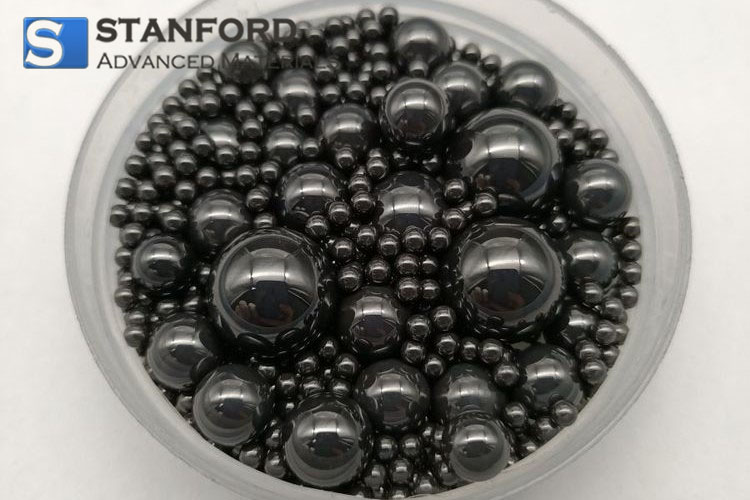

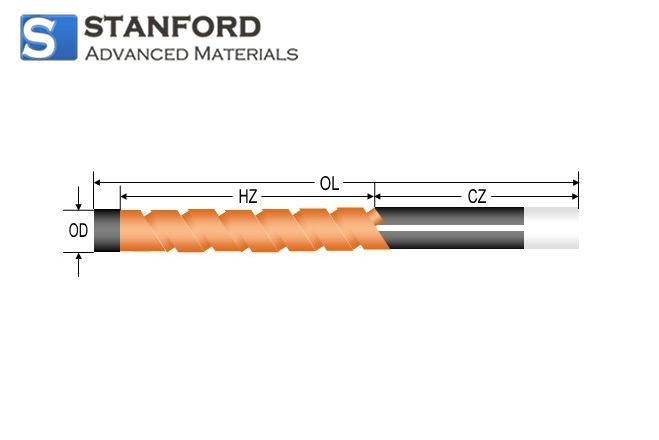

SCR Type Silicon Carbide Heating Elements (SiC) Description

SCR Type Silicon Carbide Heating Element is an electronic component that has been precisely calculated and designed based on the U-shaped silicon carbide rod. Silicon Carbide Heating Element has the advantages of high-temperature control accuracy, convenient wiring, and small temperature difference. When an electric current is passed through the silicon carbide material, it heats up due to its resistance, providing high-temperature conditions for various industrial processes.

SCR Type Silicon Carbide Heating Elements (SiC) Specifications

|

Material

|

Silicon Carbide

|

|

Color

|

Black

|

|

Density

|

2.6g/cm3-2.8g/cm3

|

|

Hardness

|

9.5 Mohs

|

|

Specific Heat

|

0.17 kcal/kg

|

|

Size

|

Diameter: 8-40mm

Length: 220-4000mm

|

|

Working Temperature Range

|

1200-1400℃

|

|

Degree expansion coefficient

|

5*10-6

|

SCR Type Silicon Carbide Heating Elements (SiC) Applications

Heat Treatment Furnaces: SCR type SiC heating elements are used in heat treatment processes such as annealing, hardening, tempering, and carburizing. They provide uniform and precise heating, ensuring consistent metallurgical properties in treated materials.

2. Ceramic and Glass Kilns: Employed in kilns for firing ceramics, pottery, and glass. The high-temperature capability and durability of SCR type SiC heating elements are crucial for achieving the desired properties in ceramic and glass products.

3. Metal Processing: In the metallurgical industry, SCR type SiC heating elements are used in furnaces for melting, casting, and refining metals, including non-ferrous metals like aluminum and copper. Their resistance to high temperatures and corrosive environments makes them ideal for metal processing applications.

4. Laboratory Furnaces: Essential in laboratory settings for high-temperature research, testing, and material development. SCR type SiC heating elements provide reliable and stable heating required for experimental work.

5. Semiconductor Manufacturing: Utilized in diffusion furnaces and other high-temperature processes in the semiconductor industry. Their high purity and thermal stability are critical for producing high-quality semiconductor devices.

6. Petrochemical Industry: Employed in reactors and reformers for high-temperature processes such as steam reforming and catalytic cracking. The chemical resistance and thermal shock resistance of SCR type SiC heating elements makes them suitable for harsh petrochemical environments.

7. Powder Metallurgy: Used in sintering furnaces to heat compacted metal powders to high temperatures, promoting solid-state diffusion and forming dense, strong metal parts. SCR type SiC heating elements ensure efficient and uniform heating.

8. Environmental Testing: Employed in test chambers and environmental simulation equipment that require high temperatures to test the durability and performance of materials under extreme conditions. SCR type SiC heating elements provide consistent and reliable heating for these tests.

9. Food Processing: Utilized in specialized ovens and dryers for processes such as dehydration, baking, and roasting. Their ability to maintain high temperatures and uniform heat distribution is essential for food processing applications.

10. Textile Industry: Employed in drying and heat-setting processes where consistent and high temperatures are needed for treating synthetic and natural fibers. SCR type SiC heating elements ensure efficient and uniform heating.

11. Renewable Energy Systems: Used in solar thermal power plants and other renewable energy applications where high-temperature heat sources are required for efficient energy conversion. SCR type SiC heating elements contribute to the efficient operation of these systems.

12. Automotive Industry: Utilized in production processes that require high temperatures, such as brazing, welding, and coating applications. The durability and high-temperature performance of SCR type SiC heating elements makes them suitable for demanding automotive manufacturing processes.

13. Incineration and Waste Treatment: Employed in high-temperature incineration and waste treatment facilities to achieve complete combustion of waste materials. SCR type SiC heating elements ensure efficient and stable high-temperature operation.

14. Graphitization Furnaces: Used in the production of graphite materials, where very high temperatures are required to convert carbon materials into graphite. SCR type SiC heating elements provide the necessary high-temperature capability and stability.

SCR Type Silicon Carbide Heating Elements (SiC) Packaging

Our Silicon Carbide Heating Elements are carefully handled during storage and transportation to preserve the quality of our product in its original condition.

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano