Refractory Grade Calcia Stabilized Zirconia Powder Description

Refractory Grade Calcia Stabilized Zirconia Powder, produced by the electric melting quenching process, can be broken into different varieties. It is used to produce various zirconia ceramics and refractory products, mainly used for electronic burning plate, sizing nozzle, sliding plate, invasive nozzle, zirconia products and special kiln furniture.

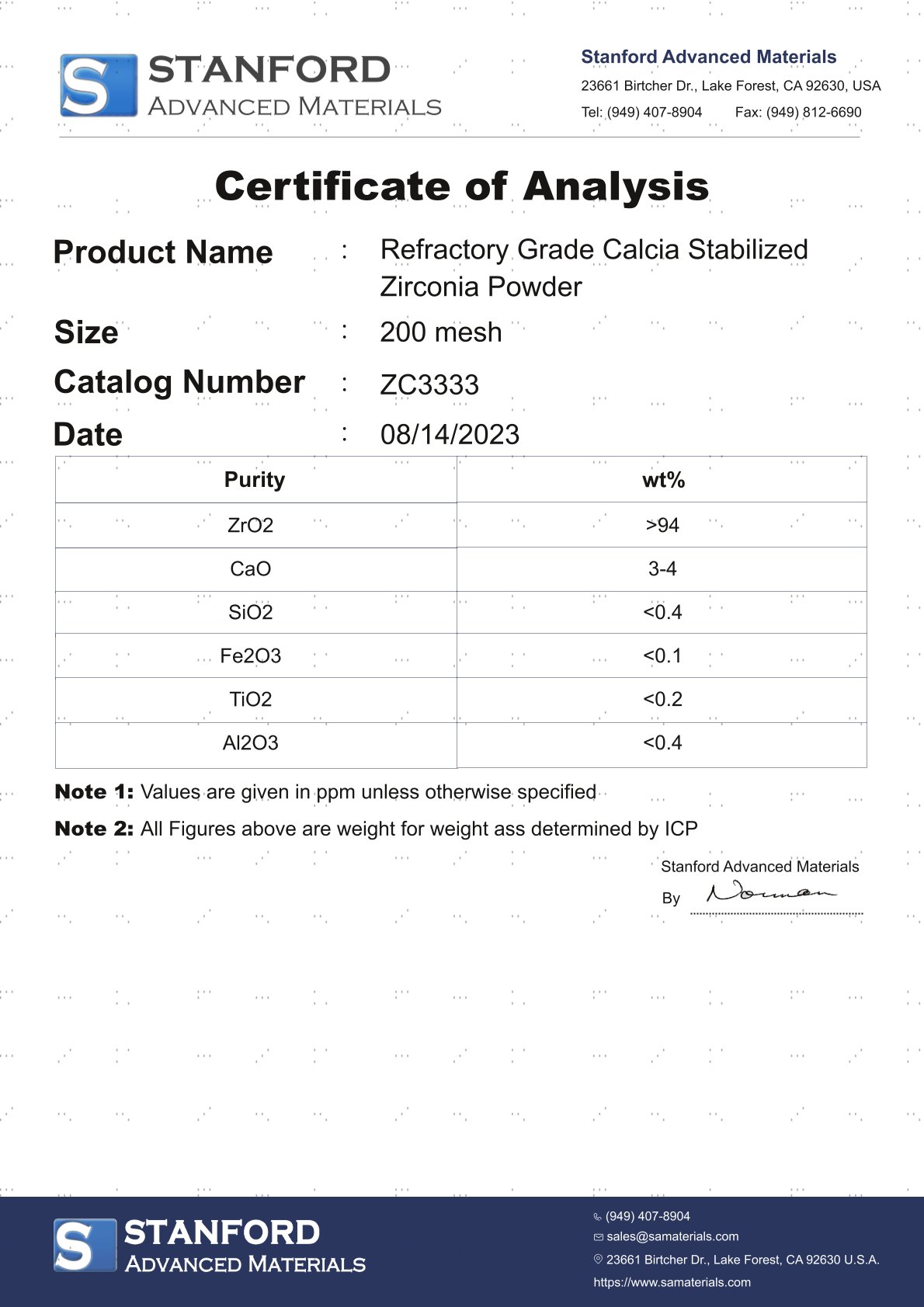

Refractory Grade Calcia Stabilized Zirconia Powder Specifications

|

Type

|

CaPSZ-5

|

CaPSZ-6

|

CaPSZ-7

|

|

Chemical Composition (wt%)

|

ZrO2

|

>94

|

>98

|

>94

|

|

CaO

|

3-4

|

<2

|

3-4

|

|

SiO2

|

<0.4

|

<0.2

|

<0.6

|

|

Fe2O3

|

<0.1

|

<0.1

|

<0.1

|

|

TiO2

|

<0.2

|

<0.2

|

<0.2

|

|

Al2O3

|

<0.4

|

<0.2

|

<0.4

|

|

Stabilization%

|

70

|

70-80

|

>95

|

Refractory Grade Calcia Stabilized Zirconia Powder Applications

1. Refractory Linings: Utilized in the lining of furnaces, kilns, and reactors, providing durability and resistance to thermal shock and chemical attack in high-temperature industrial processes.

2. Crucibles and Molds: Employed in the manufacturing of crucibles and molds for metal casting and glass production, where high melting points and resistance to molten materials are essential.

3. Thermocouple Protection Tubes: Used to protect thermocouples in high-temperature environments, ensuring accurate temperature measurement and extended sensor life.

4. Industrial Furnaces: Integrated into components of industrial furnaces, such as bricks, tiles, and other shapes, to withstand extreme temperatures and aggressive atmospheres.

5. Glass Manufacturing: Applied in glass melting and forming equipment, where it resists erosion and corrosion from molten glass and high temperatures.

6. Metal Processing: Utilized in the production of parts and tools exposed to high temperatures and corrosive environments during metal smelting, refining, and processing.

7. Aerospace and Defense: Employed in the manufacturing of components that must endure extreme temperatures and mechanical stress, such as turbine engine parts and heat shields.

8. Chemical Processing: Used in high-temperature reactors, piping, and vessels that handle corrosive chemicals and require materials with exceptional chemical and thermal resistance.

9. Ceramic and Advanced Material Production: Applied in the production of advanced ceramics and materials that require high thermal stability and resistance to wear and corrosion.

Refractory Grade Calcia Stabilized Zirconia Powder Packaging

Our Refractory Grade Calcia Stabilized Zirconia Powder is deliquescent and will be kept sealed. It will be carefully handled during storage and transportation to preserve the quality of our product in its original condition. It will be packed in vacuum packing in carton or iron drum.