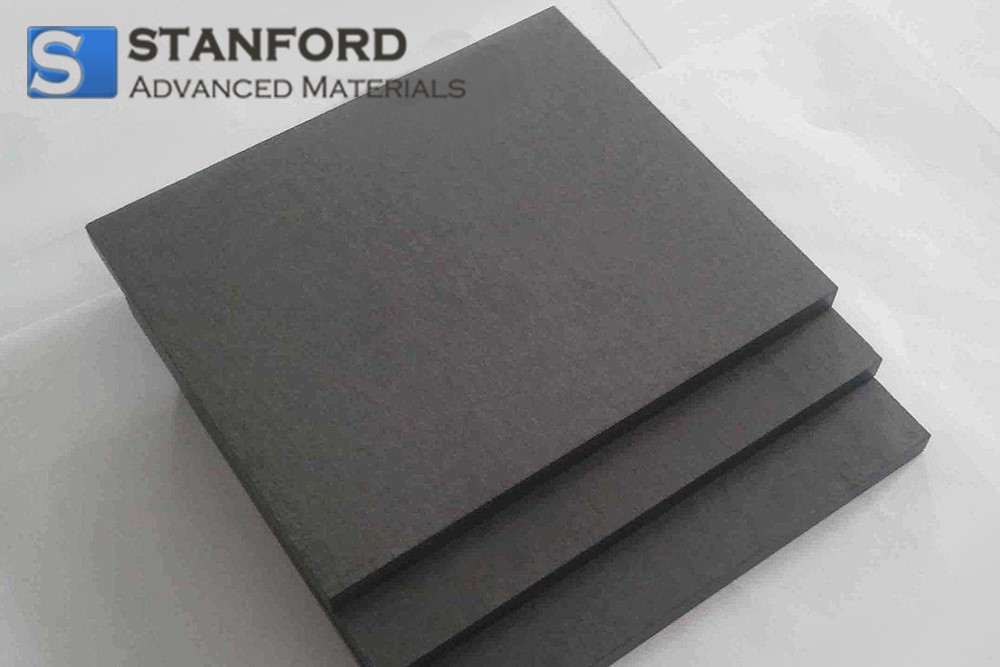

Niobium Hafnium Alloy Sheets & Boards Description

Niobium Hafnium Alloy Sheets & Boards, composed of a blend of niobium and hafnium, exhibit exceptional properties suitable for a wide range of applications. Renowned for their high strength, corrosion resistance, and thermal stability, these sheets and boards are extensively utilized in aerospace, electronics, and medical industries. Their versatility allows for applications in structural components, electronic substrates, and medical implants. With precise engineering and high-quality construction, Niobium Hafnium Alloy Sheets & Boards ensure reliability and performance in critical environments. Stanford Advanced Materials offers premium-grade Niobium Hafnium Alloy Sheets & Boards, providing solutions for diverse applications where durability and precision are paramount.

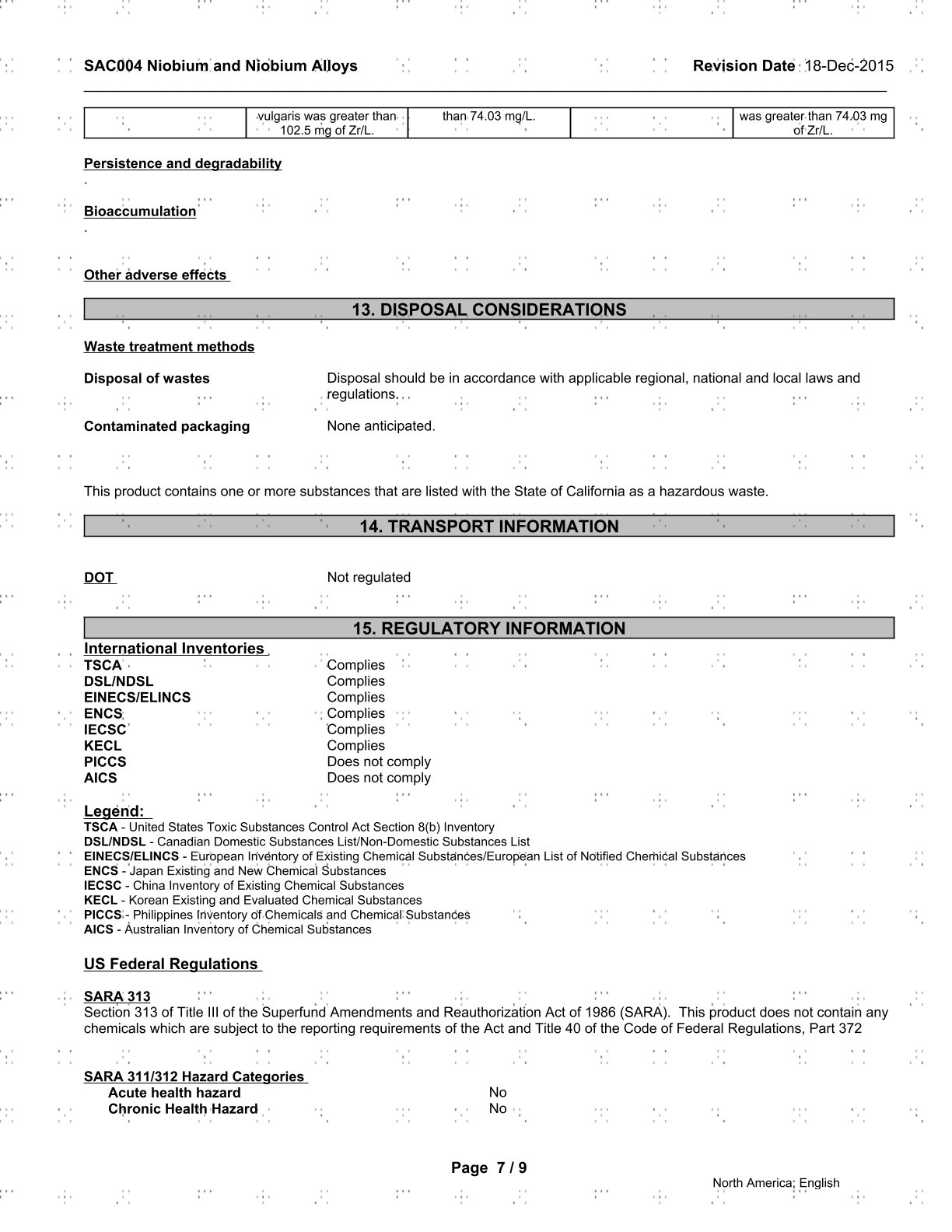

Niobium Hafnium Alloy Sheets & Boards Specification

|

Surface

|

Polished

|

|

Size

|

20 mm*(30-50) mm*(30-50) mm

|

|

Material

|

R04295 (Nb-10Hf) Nb-10W-10Hf (Niobium 10%Tungsten

|

|

Purity

|

99.9% 99.95% 99.99%

|

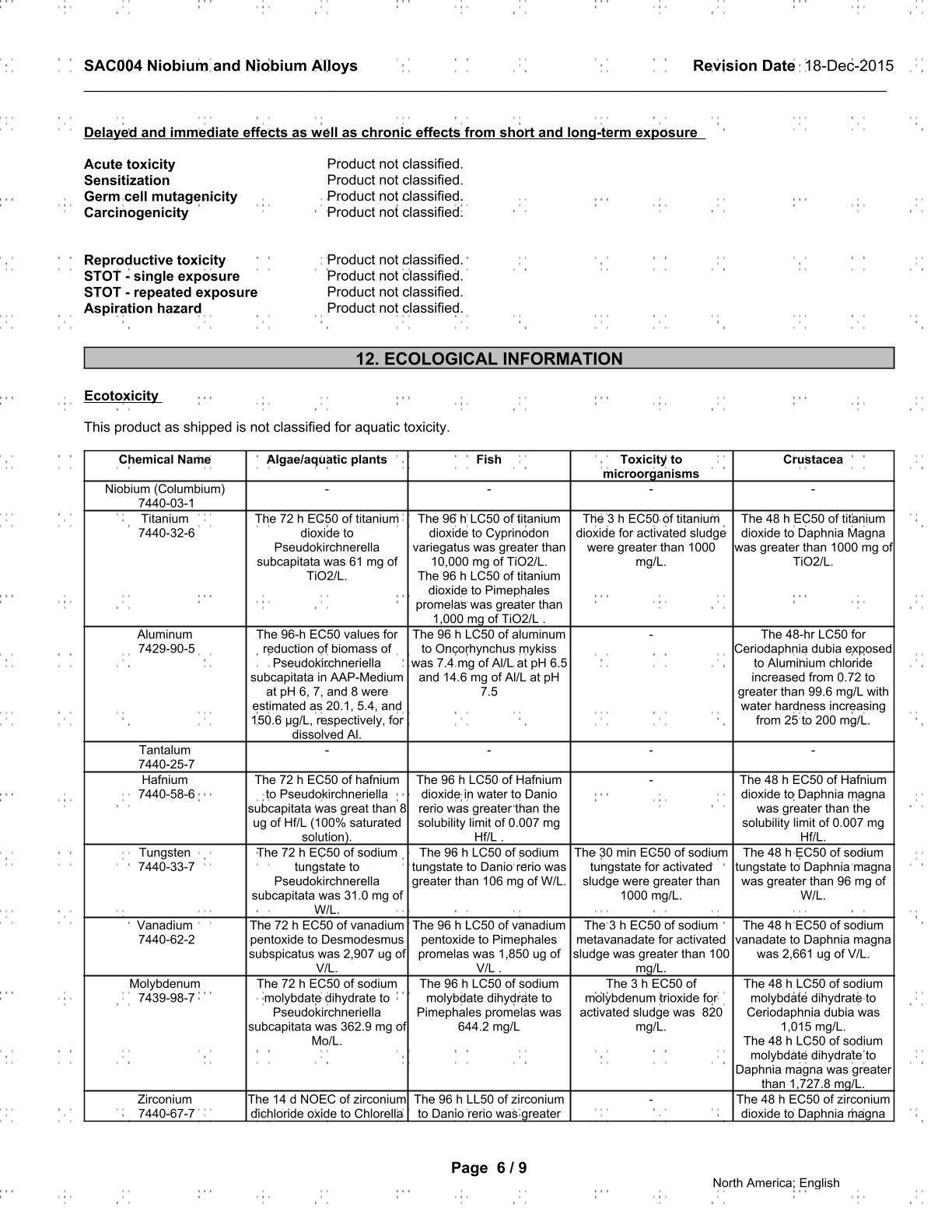

Niobium Hafnium Alloy Sheets & Boards Applications:

Aerospace: Niobium Hafnium Alloy Sheets and boards are utilized in aerospace applications, such as aircraft engine components, due to their high-temperature resistance and mechanical strength.

Chemical Processing: They find use in the construction of equipment for chemical plants and reactors, where resistance to corrosion is paramount.

Superconducting Magnets: These alloys are integral in the creation of superconducting magnets used in medical MRI machines, particle accelerators, and scientific research instruments.

Medical Devices: Their biocompatibility makes them ideal for use in medical implants, including pacemakers, dental implants, and surgical instruments.

Advanced Electronics: Niobium Hafnium Alloys are crucial for the development of cutting-edge electronic devices, contributing to advancements in quantum computing, high-performance semiconductors, and electronics research.

Niobium Hafnium Alloy Sheets & Boards Features:

High Melting Point: Niobium Hafnium Alloy boasts an exceptionally high melting point, rendering it capable of withstanding extreme temperatures without losing structural integrity.

Outstanding Corrosion Resistance: These alloys exhibit exceptional resistance to corrosion, making them ideal for use in chemically aggressive environments, including those involving acids and alkalis.

Exceptional Mechanical Properties: Niobium Hafnium Alloy Sheets & Boards offer impressive mechanical strength, ductility, and toughness, ensuring longevity and reliability in challenging conditions.

Superconductivity: At cryogenic temperatures, these alloys exhibit superconducting properties, making them pivotal in the development of advanced electronic devices and superconducting magnets.

Biocompatibility: Niobium Hafnium Alloys are biocompatible, non-reactive, and well-tolerated by the human body, making them suitable for medical implants and surgical instruments.

Niobium Hafnium Alloy Sheets & Boards Packing

Our Niobium Hafnium Alloy Sheets and boards are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

FAQs

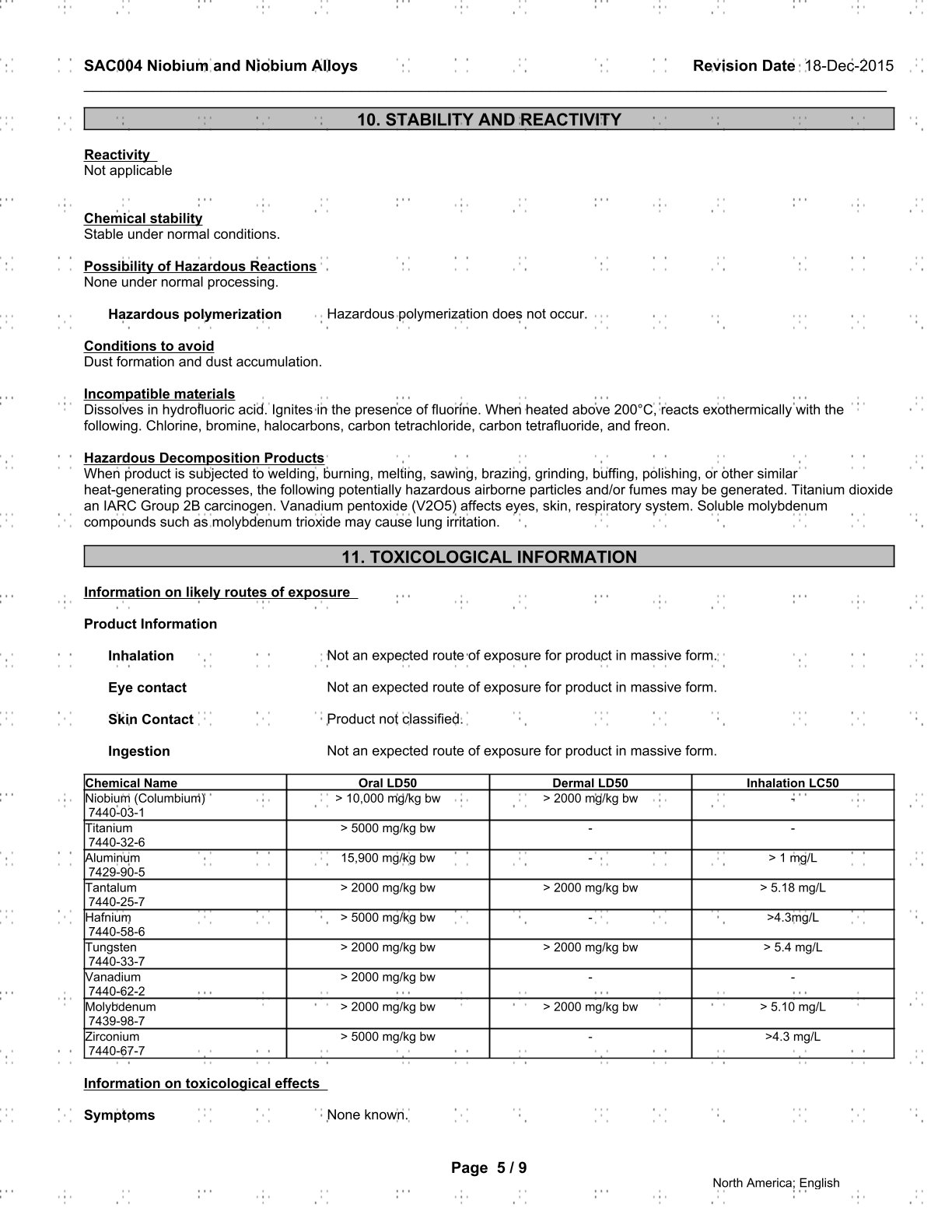

Q1: What are the main properties of Niobium Hafnium Alloy Sheets & Boards?

A1: High-temperature strength: The alloy retains excellent mechanical strength even at elevated temperatures, which is crucial for aerospace, nuclear, and high-heat industrial applications.

Corrosion resistance: Niobium Hafnium alloy has exceptional resistance to oxidation and corrosion, especially at high temperatures, making it ideal for aggressive chemical and high-temperature environments.

Radiation resistance: This alloy performs well in radiation-rich environments, which makes it a perfect material for nuclear reactors and related applications.

Ductility: It remains ductile even at high temperatures, which makes it easy to form and machine into different shapes.

Low thermal expansion: This property ensures dimensional stability in applications where thermal expansion could be an issue, such as in precision aerospace or nuclear components.

Q2: What is the maximum temperature Niobium Hafnium Alloy Sheets & Boards can withstand?

A2: Niobium Hafnium Alloy Sheets & Boards can withstand temperatures up to 2,000°C (3,632°F) or higher, depending on the specific alloy composition and processing. This makes them suitable for extreme environments like aerospace, nuclear reactors, and other high-temperature industrial applications.

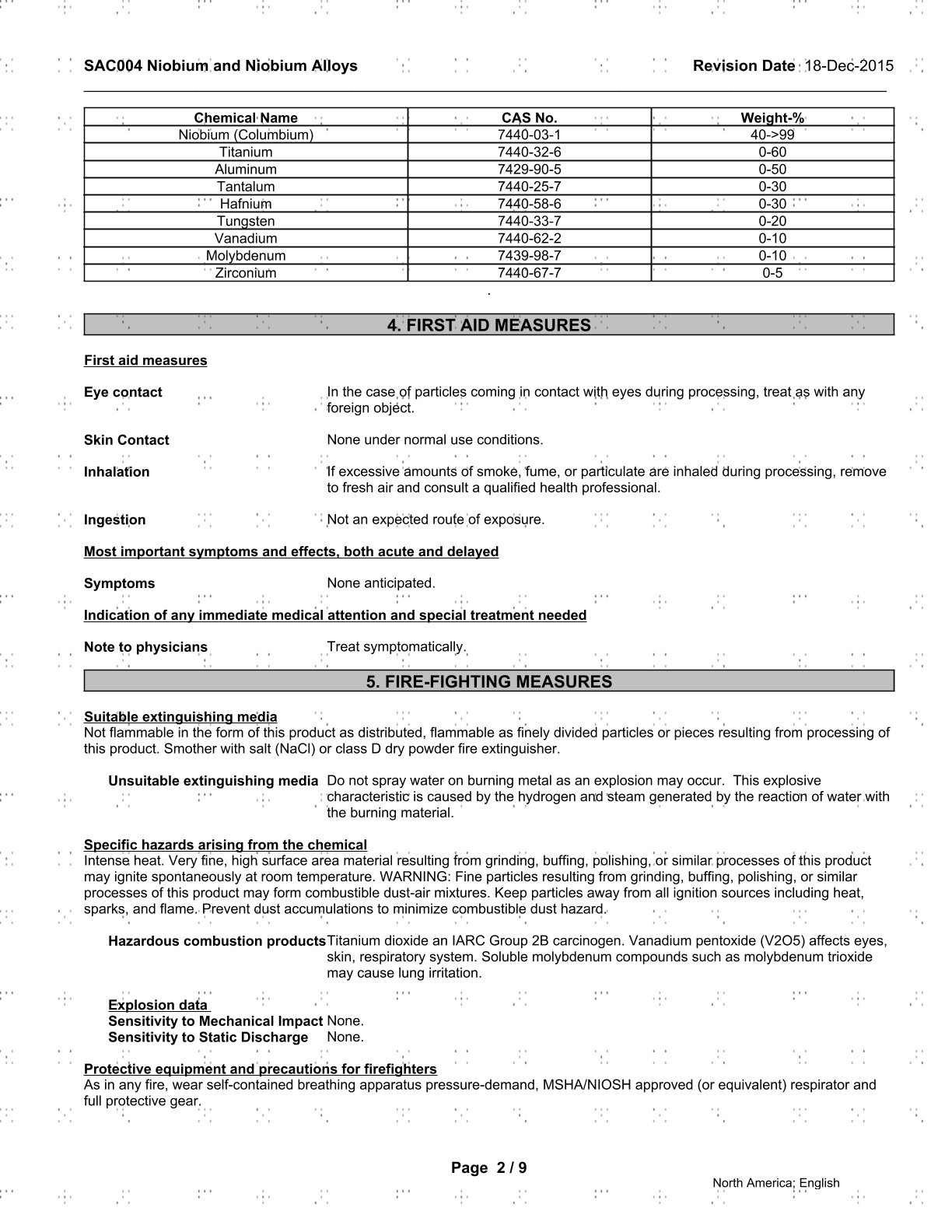

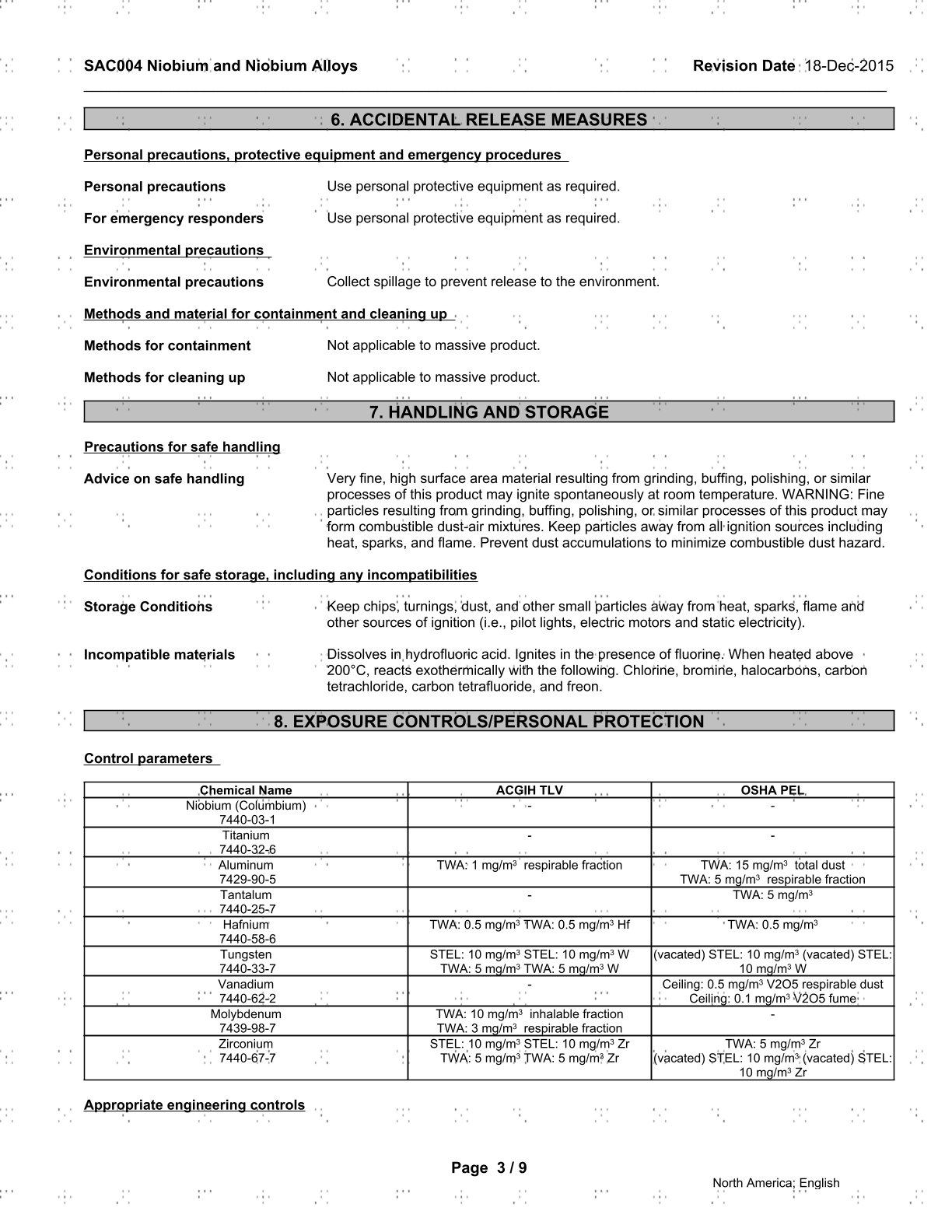

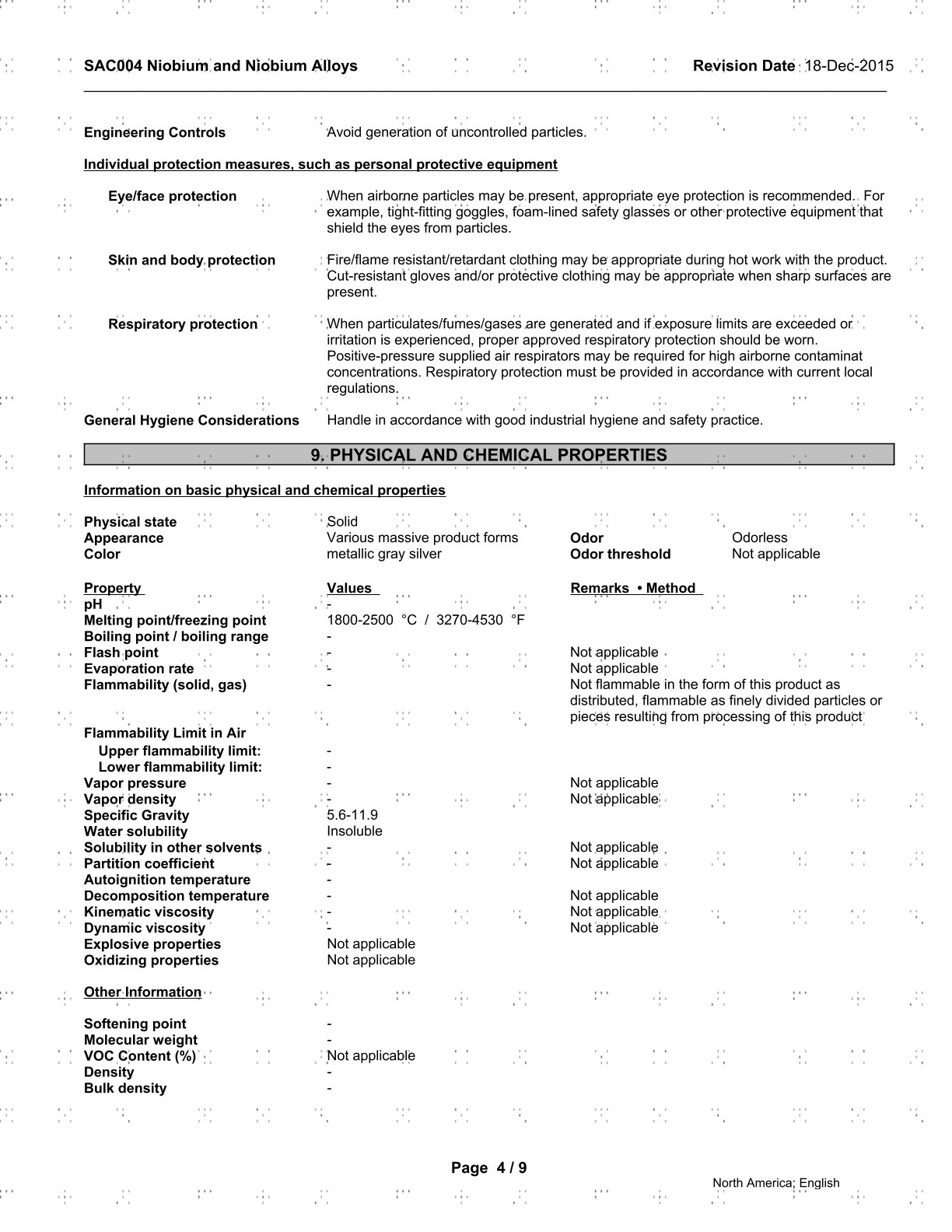

Q3: Are there any specific safety considerations when using Niobium Hafnium Alloy Sheets & Boards?

A3: Cutting and machining: When cutting, grinding, or machining Niobium Hafnium Alloy, it is essential to use proper protective equipment, such as eye protection and respiratory protection, as fine dust or metal shavings could pose a health hazard.

Handling hot materials: If the alloy is exposed to high temperatures during processing, appropriate safety measures should be taken to avoid burns or injuries.

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano