410 Stainless Steel Powder Description

410 Stainless Steel Powder is primarily composed of iron, chromium, and carbon, with smaller amounts of other elements. It is a martensitic stainless steel known for its high strength, hardness, and corrosion resistance. It exhibits excellent wear resistance, good ductility, and moderate corrosion resistance in various environments. 410 Stainless Steel Powder is widely used in a range of applications that require high strength and corrosion resistance.

410 Stainless Steel Powder Specifications

|

Particle Size

|

15~45μm, or customized

|

|

Bulk Density (g/cm3)

|

2.6-3.2

|

|

Purity

|

99.9%

|

|

Morphology

|

spherical

|

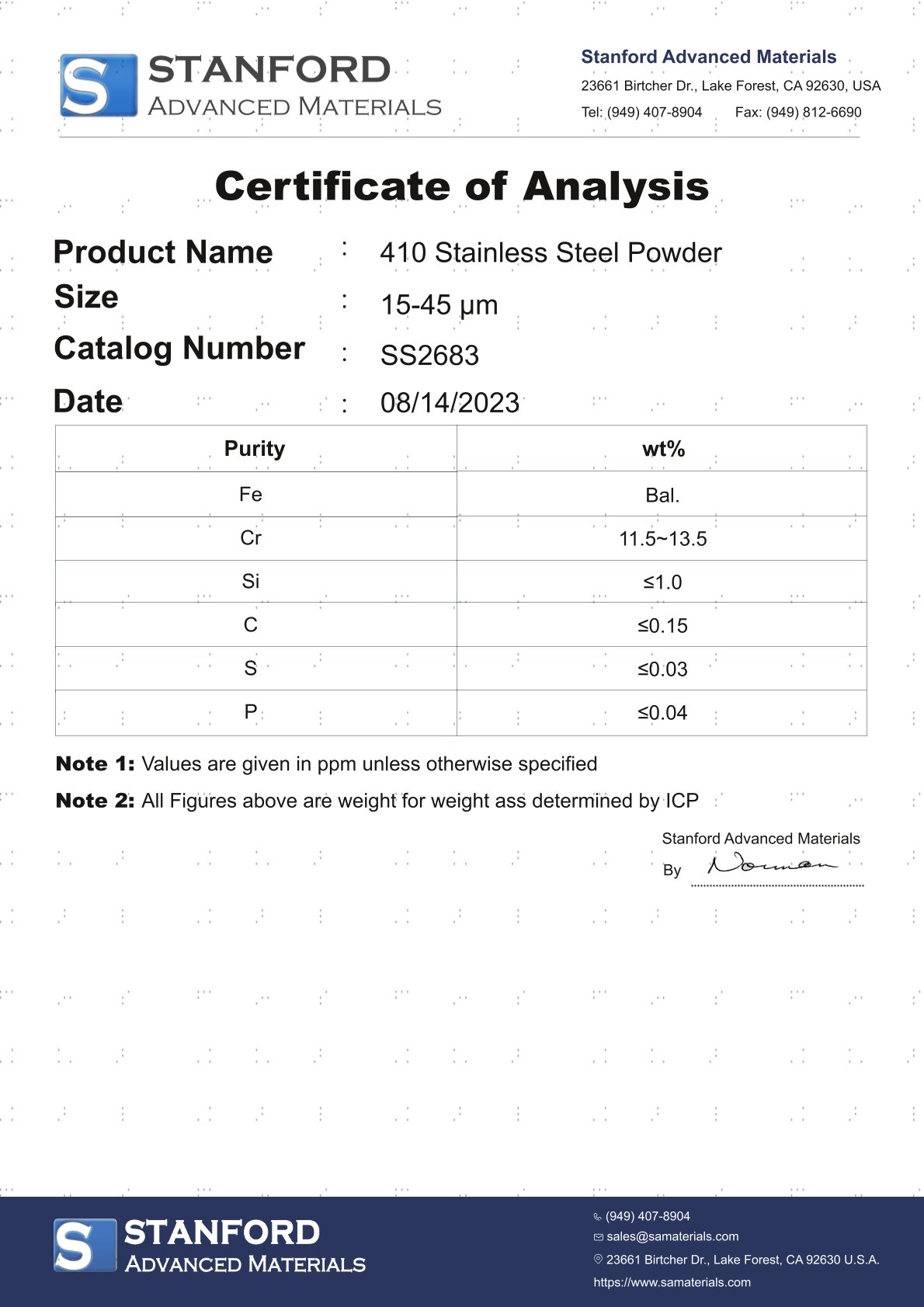

410 Stainless Steel Powder Content

|

Element

|

Fe

|

Cr

|

Si

|

C

|

S

|

P

|

|

wt%

|

Bal.

|

11.5~13.5

|

≤1.0

|

≤0.15

|

≤0.03

|

≤0.04

|

410 Stainless Steel Properties

|

Elongation at break (%)

|

< 38.0

|

|

Hardness - Brinell

|

140 - 175

|

|

Izod impact strength (J·m⁻¹)

|

10.0 - - 136.0

|

|

Modulus of elasticity (GPa)

|

190.0 - 210.0

|

|

Tensile strength (MPa)

|

480.00 - 1500.00

|

|

Density (g/cm3)

|

7.73

|

410 Stainless Steel Powder Applications

- Powder Metallurgy (PM): 410 Stainless Steel Powder is commonly used in powder metallurgy processes such as compaction and sintering to manufacture high-strength stainless steel components. These components find applications in the automotive, aerospace, and industrial sectors, where mechanical strength and wear resistance are crucial.

- Metal Injection Molding (MIM): The powder is utilized in the MIM process to produce small and intricate stainless steel parts with excellent dimensional accuracy and mechanical properties. It is suitable for applications in the medical, electronics, and consumer goods industries.

- Additive Manufacturing (AM): 410 Stainless Steel Powder is used in additive manufacturing techniques such as selective laser melting (SLM) or electron beam melting (EBM) to fabricate complex stainless steel parts. The resulting parts exhibit high strength, hardness, and corrosion resistance, making them suitable for various industrial applications.

- Tooling and Cutting Applications: The powder is employed in the production of tooling components, such as molds, dies, and cutting tools. The high hardness and wear resistance of 410 stainless steel make it suitable for applications that require cutting, shaping, and forming of materials.

- Corrosion-Resistant Components: 410 Stainless Steel Powder is used to fabricate corrosion-resistant components for applications in industries such as marine, oil and gas, and chemical processing. The powder's corrosion resistance ensures the longevity and reliability of the components in harsh environments.

- Bearings and Bushings: The powder is utilized in the manufacturing of bearings and bushings that require high strength, wear resistance, and corrosion resistance. These components find applications in the automotive, industrial, and machinery sectors.

410 Stainless Steel Powder Packaging

Our 410 Stainless Steel Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

.jpg)