NN0238 Micro Silicon Powder (Si) (CAS No.7440-21-3)

| Catalog No. | NN0238 |

| Purity | 99%-99.999% |

| Specific Surface Area(m2/g) | 21 |

| Bulk Density(g/cm3) | 1.24 |

| Tap Density(g/cm3) | 3.39 |

| Morphology | Crystalline |

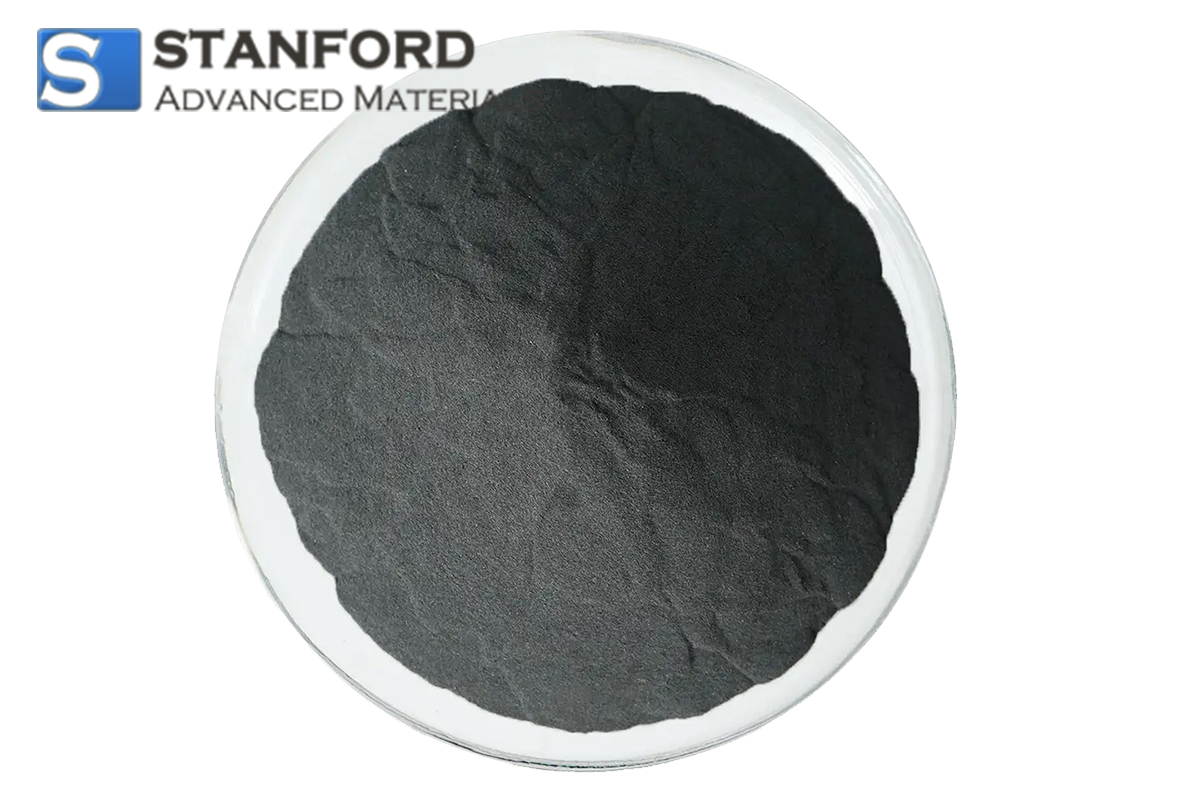

| Color | Gray |

| Chemical Formula | Si |

| CAS Number | 7440-21-3 |

| Particle Size | 1-1000um, customized |

Micro silicon powder has diverse uses in traditional & high-tech industries like mechanics, electronics, aeronautics, metallurgy, chemistry, environment, etc.

Related products: Nano Silicon Oxide (SiO2) Powder, Nano Silicon Nitride (Si3N4) Powder

Micro Silicon Powder Description

Micro silicon powder, also known as micro silica or silica fume, is a fine powder. It is composed mainly of amorphous silicon dioxide (SiO2) and is produced as a byproduct of the silicon and ferrosilicon alloy production process.

Micro Silicon Powder Specification

|

Catalog No. |

NN0238 |

|

Purity |

99.9% |

|

Specific Surface Area(m2/g) |

21 |

|

Bulk Density(g/cm3) |

1.24 |

|

Tap Density(g/cm3) |

3.39 |

|

Morphology |

Nearly spherical |

|

Color |

Gray |

|

Chemical Formula |

Si |

|

CAS Number |

7440-21-3 |

|

Particle Size |

1-1000um, customized |

Micro Silicon Powder Applications

Micro silicon powder has diverse uses in traditional & high-tech industries like mechanics, electronics, aeronautics, metallurgy, chemistry, environment, etc.

1, Electronics: Silicon powder is used in the manufacturing of semiconductors, integrated circuits, and solar cells.

2, Rubber and Plastics: Silicon powder is added to rubber and plastic compounds to improve their mechanical properties, such as strength and flexibility.

3, Construction Materials: Silicon powder is utilized in the production of construction materials like concrete, cement, and mortar. It enhances the strength and durability of these materials and improves their resistance to chemical attack.

4, Coatings: Silicon powder is incorporated into coatings and paints to provide scratch resistance, UV resistance, and anti-corrosion properties.

5, Automotive Industry: Silicon powder is used in the manufacturing of engine parts, gaskets, seals, and other automotive components.

6, Chemical Industry: Silicon powder is employed in various chemical processes as a catalyst, desiccant, or additive to control the viscosity or flow properties of liquids.

7, Aerospace and Defense: Silicon powder is used in aerospace and defense applications due to its high heat resistance, electrical conductivity, and lightweight properties.

Micro Silicon Powder Safety Information

|

Signal Word |

Warning |

|

Hazard Statements |

H228 |

|

Hazard Codes |

F |

|

Precautionary Statements |

P210-P240-P241-P280-P370 + P378 |

|

Flash Point |

Not applicable |

|

Risk Codes |

11 |

|

Safety Statements |

16-33-36 |

|

RTECS Number |

VW0400000 |

|

Transport Information |

UN 1346 4.1/PG 3 |

|

WGK Germany |

2 |

|

GHS Pictograms |

|

Micro Silicon Powder Packing

Our Micro Silicon Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

FAQs

Q1: How does Micro Silicon Powder differ from Nano Silicon Powder?

A1: Micro Silicon Powder has a larger particle size than Nano Silicon Powder, typically in the micrometer range (1-100 microns), which makes it more suitable for certain industrial applications like concrete reinforcement or in energy storage devices where larger particles provide better structural integrity. Nano Silicon Powder, with its smaller particle size, is typically used in more specialized applications like battery anodes for higher energy densities.

Q2: What are the storage conditions for Micro Silicon Powder?

A2: Micro Silicon Powder should be stored in a cool, dry environment to prevent any exposure to moisture, which could affect its performance. It should be kept in sealed containers to avoid contamination and degradation of the material. Proper storage also helps maintain its purity and effectiveness for use in various applications.

Q3: How is Micro Silicon Powder used in energy storage applications?

A3: In energy storage, particularly in lithium-ion batteries, Micro Silicon Powder is often used as a silicon-based additive to enhance the anode material's performance. It helps improve the cycle life, capacity, and energy density of the batteries by increasing the material’s conductivity and mechanical strength.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!