Nano Copper Zinc Alloy Powder Introduction

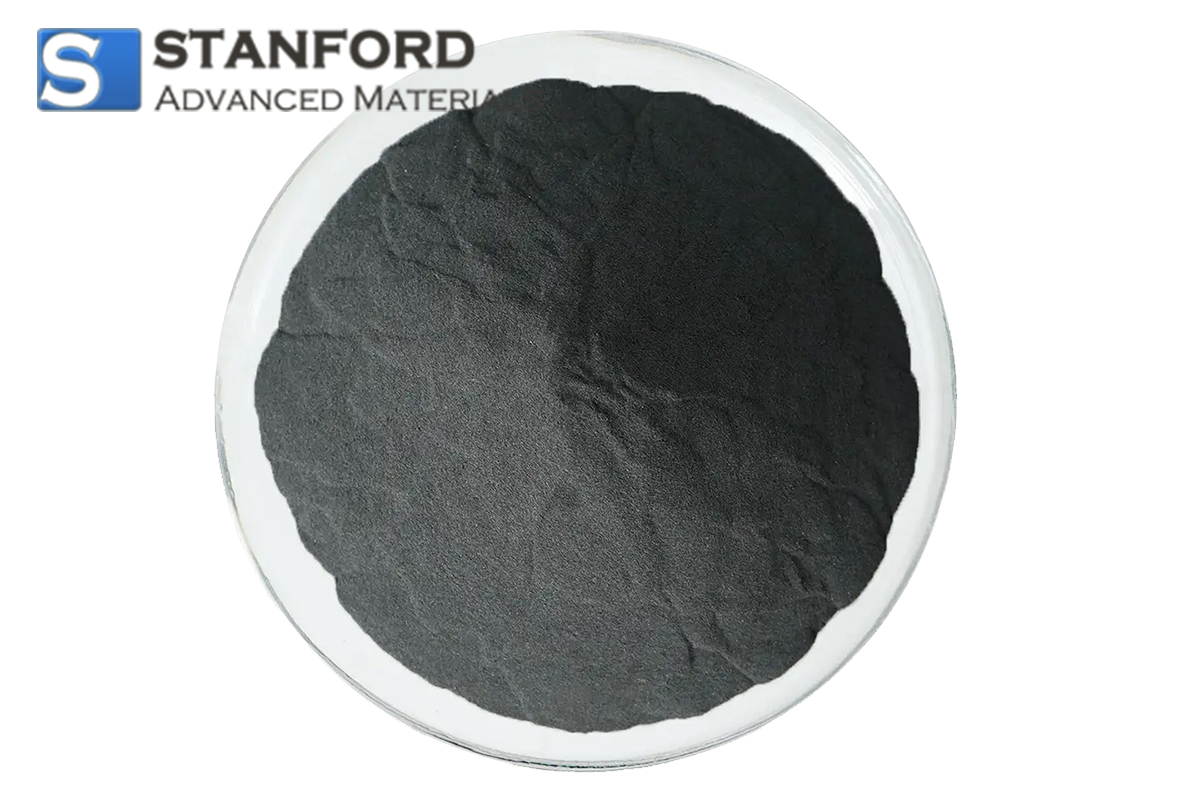

By variable current laser ion gas phase method to the preparation of particle size and composition of Cu - zinc controllable high evenly mixed nanometer copper, zinc alloy products, high purity, uniform particle size distribution, particle surface is flat, specific surface area, high surface activity.

Nano Copper Zinc Alloy Powder Specification

|

Materials

|

Copper Zinc

|

|

Purity

|

>99.5 %

|

|

APS

|

60 nm

|

|

Specific Surface Area(m2/g)

|

10.2

|

|

Color

|

Black

|

Nano Copper Zinc Alloy Powder Properties

- Enhanced Strength: Due to grain boundary strengthening mechanisms, the nanoscale structure significantly increases the alloy's tensile strength and yield strength.

- Improved Ductility

- Excellent Electrical Conductivity

- High Thermal Conductivity

- Enhanced Corrosion Resistance: The presence of zinc provides sacrificial protection to copper, improving overall corrosion resistance.

- Antimicrobial Properties: Copper and zinc ions exhibit antimicrobial activity, making the alloy suitable for medical devices, touch surfaces, and applications requiring hygienic conditions.

Nano Copper Zinc Alloy Powder Applications

- Electronics: This alloy powder is used to manufacture high-performance electrical components, such as connectors, switches, and printed circuit boards, owing to its excellent electrical conductivity.

- Antifouling Coatings: Applied as a key component in antifouling paints, it protects marine structures, ships, and boats against both corrosion and biofouling in marine environments.

- Battery Technology: Enhances battery performance, especially in terms of energy storage and charge-discharge rates, making it ideal for advanced energy storage systems.

- Additive Manufacturing: In 3D printing, it enables the creation of intricate, conductive structures and components for a wide range of applications, including customized electronics.

- Catalysis: Utilized as a catalyst in various chemical reactions due to its unique properties, contributing to the efficiency of chemical processes.

Nano Copper Zinc Alloy Powder Storage Conditions

This product should be stored in a dry, cool, and sealing of environment, can not be exposed to air, in addition, should avoid heavy pressure, according to ordinary goods transportation.

Nano Copper Zinc Alloy Powder Packing

Our Nano Copper Zinc Alloy Powder is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.