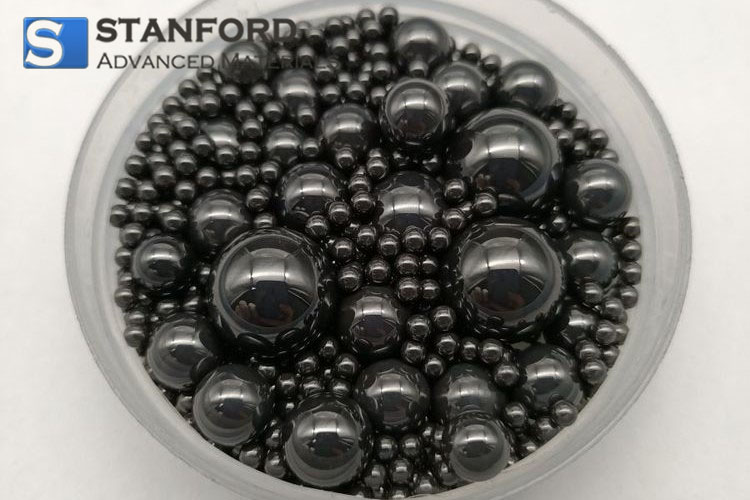

Micro Green Silicon Carbide (SiC) Powder Description

Micro Green Silicon Carbide (SiC) Powder is a kind of Silicon carbide powder. Silicon carbide (SiC) is a lightweight ceramic material with high-strength properties comparable to diamond. It has excellent thermal conductivity, low thermal expansion, and is resistant to corrosion from acids. Silicon carbide is an excellent ceramic material for applications requiring good erosion and abrasive resistance.

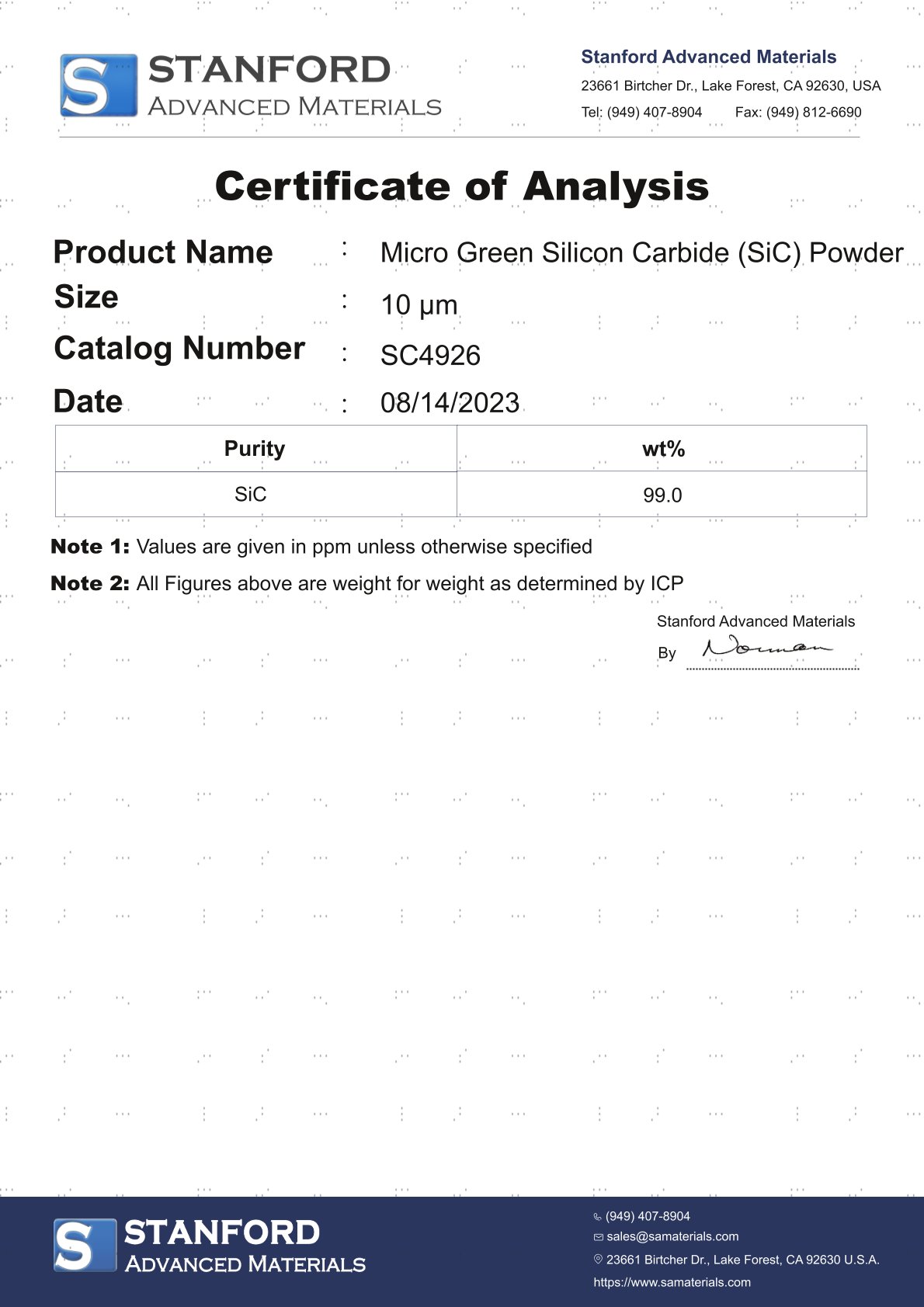

Micro Green Silicon Carbide (SiC) Powder Specification

|

Type

|

SISIC-10

|

SISIC-14

|

|

Particle Size (D50)

|

7um

|

10um

|

|

SiC

|

>99%

|

>99%

|

|

Fe3O2

|

<0.03%

|

<0.03%

|

|

Free C

|

<0.1%

|

<0.03%

|

|

SiO2

|

<0.2%

|

<0.2%

|

Micro Green Silicon Carbide (SiC) Powder Applications

Micro Green Silicon Carbide (SiC) Powder has proven to be an excellent material choice for wear applications such as pipe liners, flow control chokes, and larger wear components in mining as well as other industries.

- Pipe Liners: SiC powder is utilized in the production of pipe liners due to its exceptional hardness and wear resistance. These liners offer robust protection against abrasive materials, enhancing the durability and longevity of piping systems, particularly in industries like mining and processing.

- Flow Control Chokes: In industries requiring precise flow control, SiC powder is employed in manufacturing chokes. The material's hardness and resistance to abrasion ensure prolonged service life and efficiency in regulating flow in demanding environments.

- Mining Components: SiC-based wear components are extensively used in the mining industry for larger-scale applications, such as wear plates, conveyor systems, and equipment parts. SiC's exceptional wear resistance prolongs the lifespan of these components, reducing maintenance and downtime.

- Micro Green Silicon Carbide (SiC) Powder's remarkable hardness and wear-resistant properties make it a preferred choice for wear applications across industries, ensuring durability and performance in challenging environments subjected to abrasion and erosion.

Micro Green Silicon Carbide (SiC) Powder Safety Information

|

Signal Word

|

Warning

|

|

Hazard Statements

|

H315-H319-H335

|

|

Hazard Codes

|

Xi

|

|

Risk Codes

|

36/37/38

|

|

Safety Statements

|

26-36

|

|

RTECS Number

|

VW0450000

|

|

Transport Information

|

N/A

|

|

WGK Germany

|

3

|

Micro Green Silicon Carbide (SiC) Powder Packaging

Our Micro Green Silicon Carbide (SiC) Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Micro Green Silicon Carbide (SiC) Powder FAQs

Q1: What particle sizes are available for micro green silicon carbide powder?

A: Micro green silicon carbide powder is available in a range of particle sizes, typically from a few micrometers to several tens of micrometers, depending on the specific application requirements.

Q2: Why is green silicon carbide used in abrasive applications?

A: Green silicon carbide is used in abrasive applications because of its high hardness and sharp edges, which allow it to efficiently cut and grind hard materials. Its purity and uniform particle size distribution also contribute to its effectiveness in precision abrasive tasks.

Q3: How is micro green silicon carbide powder produced?

A: Micro green silicon carbide powder is typically produced through a process involving the high-temperature reaction of silica (SiO2) with petroleum coke in an electric arc furnace. The resulting SiC crystals are then crushed and classified into different particle sizes.