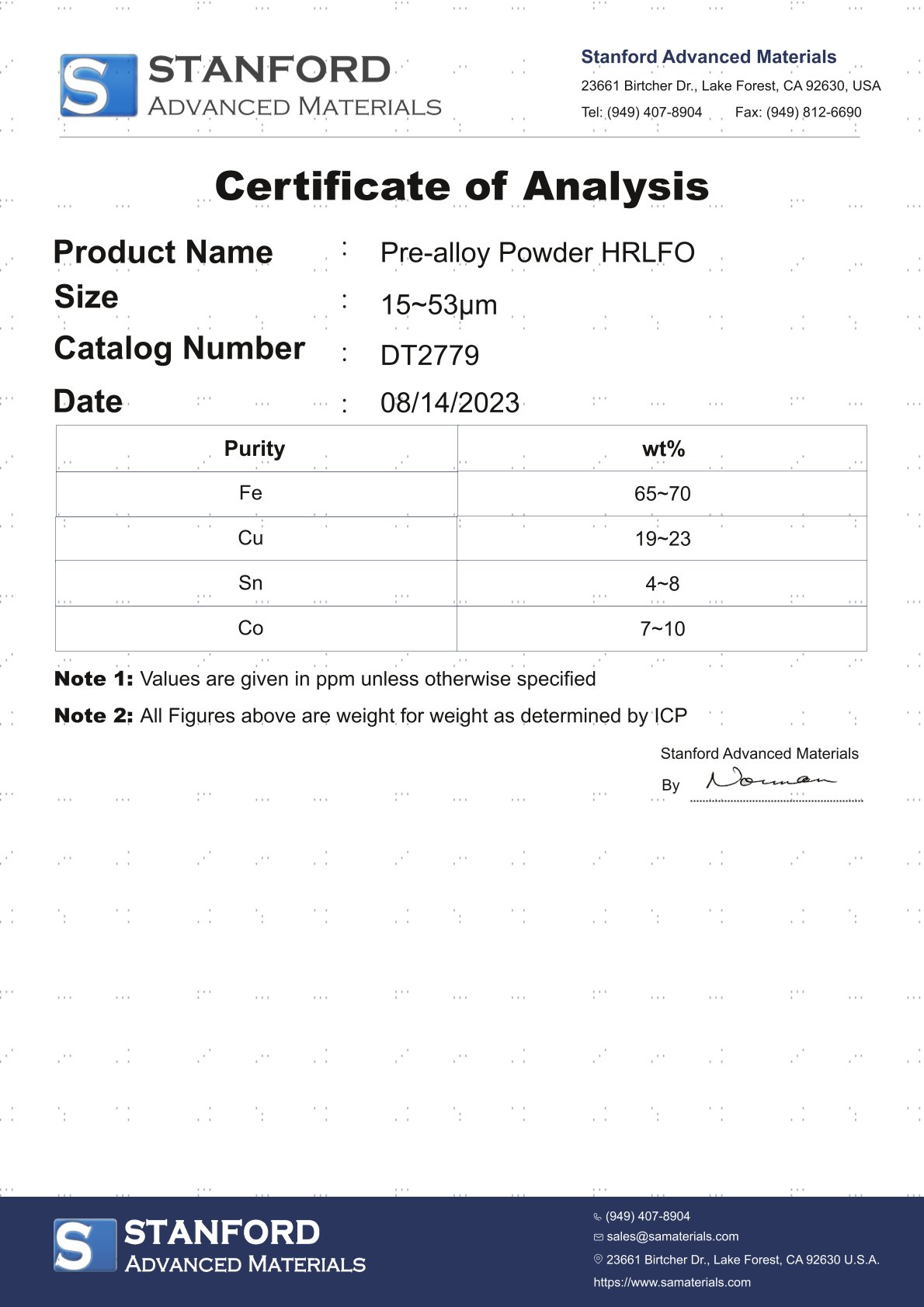

DT2779 Pre-alloy Powder HRLFO Fe-Cu-Sn-Co

| Catalog No. | DT2779 |

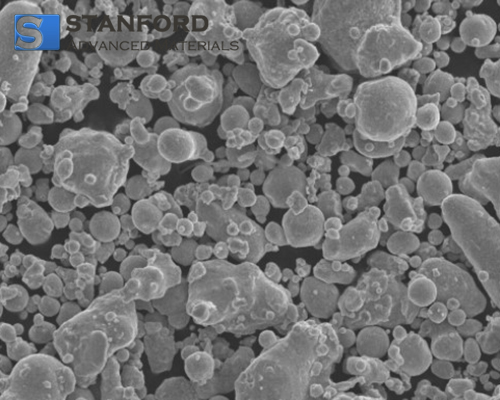

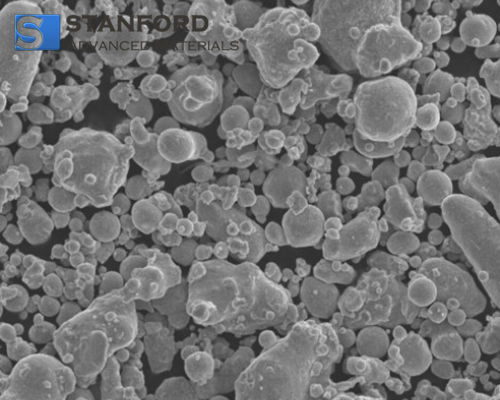

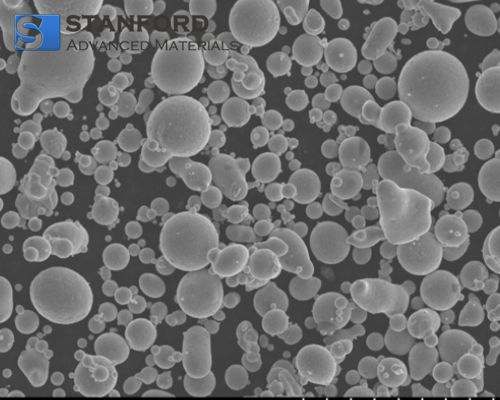

| Appearance | Dark gray metallic powder |

| Compositions | Fe:65-70 Cu:19-23 Sn:4-8 Co:7-10 other micro e |

Pre-alloy Powder HRLFO Fe-Cu-Sn-Co is on sale at Stanford Advanced Materials (SAM). With rich experience and expertise, SAM provides customers with high-quality Pre-alloy Powder HRLFO Fe-Cu-Sn-Co and other Diamond Tool Powder products.

Related Products: Cobalt Powder for Diamond Tools, Copper Powder for Diamond Tools, Pre-alloy Powder HR533, Pre-alloy Powder HRHO3, Pre-alloy Powder HRHOC, Tin Powder for Diamond Tools

Pre-alloy Powder HRLFO Description

Pre-alloy Powder HRLFO can be applied to almost all aspects of the production of super-hard materials tools, involving stone, ceramics, concrete, glass processing, and other fields. Pre-alloy Powder HRLFO and other metal compounds are mixed together with synthetic diamonds to form diamond segments usually by hot pressing or free sintering techniques.

Pre-alloy Powder HRLFO Specifications

|

Product Name |

Pre-alloy Powder HRLFO |

|

Composition |

Fe:65-70 other micro elements |

|

Grade |

LFO |

|

Flow density |

Sinter density 8.0g/cm^3 |

|

Particle size |

53μm 45μm customizable |

|

Hardness |

HRB90 |

Pre-alloy Powder HRLFO Applications

Pre-alloy Powder HRLFO can be applied to almost all aspects of the production of super-hard materials tools, involving stone, ceramics, concrete, glass processing, and other fields. Pre-alloy Powder HRLFO is widely used to improve the holding force so that the blade can cut dry. Pre-alloy Powder HRLFO can be applied under sinter temperature of 780-800℃.

FAQs

1. What is Pre-alloy Powder HRLFO Fe-Cu-Sn-Co?

HRLFO Fe-Cu-Sn-Co is a pre-alloyed powder consisting of iron (Fe), copper (Cu), tin (Sn), and cobalt (Co) in specific proportions. This alloy is designed for use in powder metallurgy processes, providing a combination of high strength, good wear resistance, and improved corrosion resistance. It is used in a wide range of industrial applications that require durable, high-performance components.

2. What are the key benefits of using Pre-alloy Powder HRLFO Fe-Cu-Sn-Co?

HRLFO Fe-Cu-Sn-Co pre-alloyed powder offers several notable advantages for manufacturing:Enhanced Strength and Durability: The combination of iron, copper, tin, and cobalt results in an alloy with improved mechanical properties. These include higher strength and toughness, making it suitable for parts that need to perform under mechanical stress. Improved Wear Resistance: The tin and cobalt in the alloy contribute to better wear resistance, making it ideal for components used in high-wear environments, such as gears, bearings, and industrial machinery parts. Corrosion Resistance: The addition of tin and cobalt enhances the corrosion resistance of the alloy, especially in harsh environments exposed to moisture, acids, or corrosive chemicals. This makes it suitable for automotive, electrical, and industrial applications. Good Machinability: The powder is easy to compact and sinter, making it suitable for precise and high-quality components. The excellent machinability reduces production costs and material wastage. Versatile Processing: HRLFO Fe-Cu-Sn-Co powder is ideal for powder metallurgy and other powder-based manufacturing techniques, including metal injection molding (MIM) and additive manufacturing.

3. What are the typical applications of Pre-alloy Powder HRLFO Fe-Cu-Sn-Co?

HRLFO Fe-Cu-Sn-Co powder is commonly used in the following applications:Automotive Components: Parts such as gears, bearings, and bushings that need to resist wear, corrosion, and high-stress conditions. Industrial Machinery: Components like pumps, valves, and shafts used in machinery where durability and wear resistance are crucial for long-term performance. Electrical Components: The cobalt content improves the powder’s electrical conductivity and resistance to oxidation, making it ideal for use in electrical contacts, connectors, and other electronic components. Tooling and Equipment: Parts used in heavy machinery, cutting tools, and molds where wear resistance and high strength are essential for performance. Powder Metallurgy: This alloy is also used in sintered parts that require high precision and performance, especially in industries such as automotive, aerospace, and industrial machinery.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!