- Products

- Categories

- Blog

- Podcast

- Application

- Document

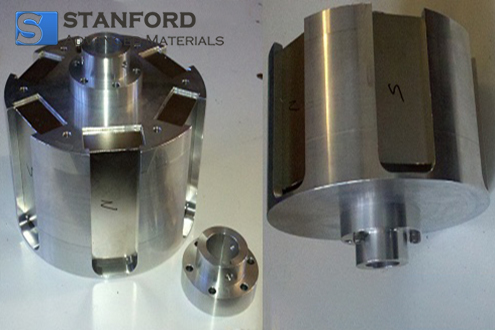

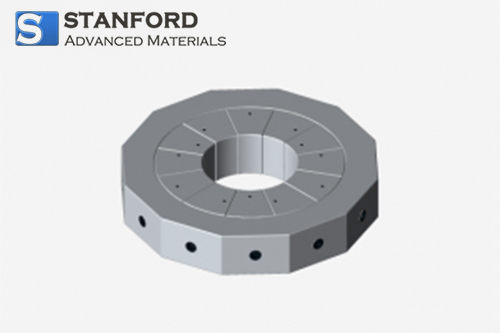

SM5096 Magnet Rotors

| Catalog No. | SM5096 |

| Outer Diameter | 450mm |

| Type | Rotated Magnet, 4 Poles |

| Grade | 38UH |

Magnetic rotor, or permanent magnet rotor is the non stationary part of a motor. The rotor is the moving part in an electric motor, generator and more. Magnetic rotors are designed with multiple poles.

INQUIRY

Add to Inquiry List

Description

Specification

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!