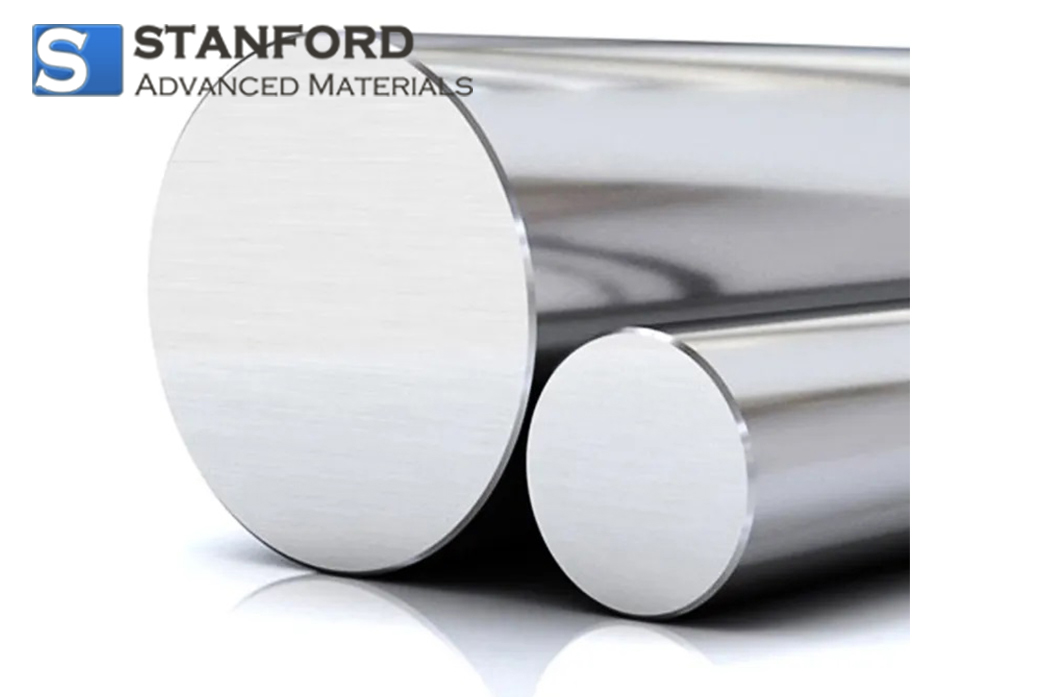

NC1178 Inconel 600 (Alloy 600, UNS N06600) Bar/Rod

| Catalog No. | NC1178 |

| Size | Customized |

| Material | nickel-chromium alloy |

| Shape | bar, rod |

| M.O.Q | $2000-$5000 |

Inconel 600 (Alloy 600, UNS N06600) is a nickel-chromium alloy known for its excellent resistance to high temperatures, corrosion, and oxidation, making it suitable for a wide range of applications in extreme environments. Stanford Advanced Materials (SAM) provides an extensive selection of specialty alloys, including Inconel, Incoloy, Monel, Hastelloy, NIMONIC, and more.

Other shapes of Inconel 600: sheet/plate, wire, flange, tube/pipe

Related products: Inconel 601, Inconel 625, Inconel 718

Inconel 600 (Alloy 600, UNS N06600) Bar/Rod Description:

Inconel 600 is a high-performance nickel-chromium alloy renowned for its exceptional corrosion resistance, oxidation resistance, and strength in high-temperature environments. It maintains outstanding stability under extreme conditions and can endure various corrosive media, including both oxidizing and reducing agents. Thanks to its excellent mechanical properties and thermal stability, Inconel 600 is extensively utilized in chemical processing, aerospace, heat-treating equipment, the nuclear industry, and other engineering applications that demand superior performance in corrosive settings. Additionally, its excellent weldability and workability make Inconel 600 an ideal material for demanding applications, ensuring durability and reliability in some of the most challenging environments.

Other trade names: Alloy 600, UNS N06600, W.NR 2.4816, AWS 010, Nickel 600, Nickelvac 600, Ferrochronin 600

Inconel 600 (Alloy 600, UNS N06600) Bar/Rod Specification:

Metal Type: UNS N06600

Standard: ASTM B166 AMS 5665 Din 17752

Chemical Composition, %

| C | Cr | Cu | Fe | Mg | Ni | S | Si | |

| Max | 0.15 | 17 | 0.5 | 10 | 1 | 0.015 | 0.5 | |

| Min | 14 | 6 | 72 |

Inconel 600 (Alloy 600, UNS N06600) Bar/Rod Applications:

Steam Generators: Utilized for its high temperature and corrosion resistance properties.

Chemical Processing: Resistant to corrosion in aggressive chemical environments.

Food Processing: Employed in equipment and components for its corrosion resistance and hygiene factors.

Superheaters: Used in the construction of superheaters in power plants due to their high-temperature strength.

Jet Engines: Applied in components exposed to high-temperature and corrosive conditions in aviation.

Electronic Parts: Used for its high-temperature strength and resistance in electronic applications.

Packing

Our Inconel 600 materials are carefully handled during storage and transportation to preserve the quality of our product in its original condition.

FAQs

Can Inconel 600 be welded easily?

Yes, Inconel 600 has excellent weldability and can be welded using standard welding techniques such as TIG, MIG, and resistance welding. Preheating is generally not required, and it exhibits minimal sensitivity to sulfide stress cracking. However, proper welding procedures should be followed to maintain its corrosion resistance and mechanical properties in the welded areas.

How does Inconel 600 perform at high temperatures?

Inconel 600 maintains its mechanical strength and stability at high temperatures, up to approximately 1,100°F (600°C). Its ability to resist oxidation and maintain structural integrity makes it ideal for applications involving thermal fatigue and thermal cycling. This thermal stability ensures longevity and reliability in environments subjected to extreme heat.

LATEST RECOMMENDED

Powder.jpg)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!