High-entropy Alloys for Thermoelectric Applications

Introduction

High-entropy alloys (HEAs) have recently emerged as promising materials for high-temperature thermoelectric applications due to their unique properties. Here are some benefits of using HEAs for thermoelectric applications. Hope that you can have a better understanding of the features and applications of high-entropy alloys.

What Is High-entropy Alloy?

High-entropy alloy is a type of alloy containing at least 5 elements, the proportion of which are equal or approximately equal. Compared with traditional alloys, they do not have one single base element, but are made of several principal elements. Such unique composition leads to disordered structure, high entropy, and most importantly, exceptional properties and applications.

HEAs stand out for their unique and impressive properties that conventional alloys do not have. These features involve high strength, great ductility, high electrical conductivity, and superior thermal stability. These alloys possess excellent wear resistance, corrosion resistance, and high-temperature properties as well, which make them ideal materials in harsh environments.

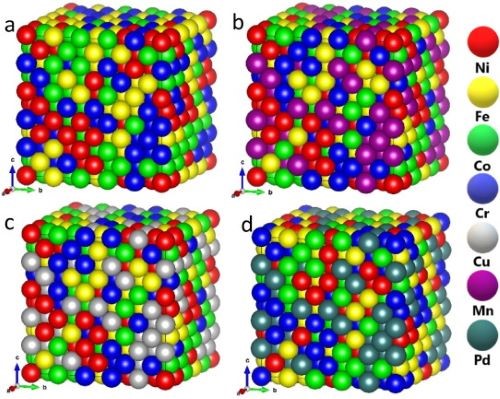

[1]

[1]

Figure 1. High-entropy Alloy Examples

With these structural and functional properties, HEAs have a variety of applications, including aerospace, automotive, and biomedical applications. This article is going to explore high-entropy alloys used for thermoelectric applications particularly.

What Are Thermoelectric Materials?

The popularity of thermoelectric (TE) technology increases rapidly as the energy demand increases constantly. For one thing, a large quantity of renewable energy is utilized to meet the rising energy demand. For another, TE technology is an attractive option since it can use the energy of waste heat. TE materials also come with a small operational size, and they can be applied to solid-state cooling, portable and wearable electronics, etc.

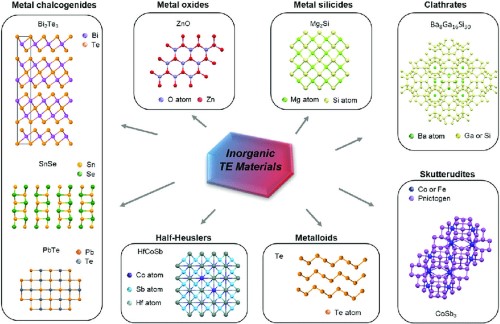

A broad range of advanced materials is employed for the direct conversion of waste heat energy into electrical power in TE technology. Common thermoelectric materials are Zintl, Heusler, SiGe, MgSi, clathrates, and CoSb3-Ba. Pb(Te, Se, S)-SeTe, SiGe, and skutterudites are also useful. [2] Yet, various high-entropy alloys emerge as new cutting-edge TE materials with high-temperature properties.

[3]

[3]

Figure 2. TE Material Examples

Why High-entropy Alloys Are Suited for Thermoelectric Applications?

HEAs are quite suitable for TE applications for the following characteristics.

--High Thermal Stability

First, they exhibit high thermal stability due to their high configurational entropy, which results in a random distribution of atoms. This disordered structure reduces the occurrence of phase transformations, even at high temperatures, making HEAs excellent materials for thermoelectric applications.

--High Thermal Conductivity

Second, their metallic nature determines their high thermal conductivity, which brings about high electron mobility and low resistance to the flow of heat. This makes HEAs excellent TE materials because high thermal conductivity is desired to enhance heat transfer efficiency in TE applications.

--High Electrical Conductivity

Apart from thermal properties, HEAs show high electrical conductivity, which allows for the efficient conversion of heat to electricity. Therefore, HEAs become an excellent choice for thermoelectric power generation.

--Low Thermal Expansion Coefficient

HEAs have a low thermal expansion coefficient because of their random atomic arrangement. This reduces the likelihood of thermal stress or deformation, making HEAs excellent materials for thermoelectric applications.

--Enhanced Mechanical Properties

Additionally, the disordered structure leads to the enhanced mechanical properties of HEAs, such as high strength and ductility. These mechanical features render HEAs excellent materials for high-temperature thermoelectric applications since materials with high strength and ductility are needed to withstand harsh operating conditions.

Conclusion

In a word, HEAs offer numerous benefits for thermoelectric applications, including high thermal stability, high thermal and electrical conductivity, low thermal expansion coefficient, and enhanced mechanical properties. These unique properties make HEAs a promising alternative to traditional TE materials and could lead to the development of more efficient and durable thermoelectric devices.

Stanford Advanced Materials (SAM) is a reliable supplier of high-entropy alloys. There are lots of quality HEAs used for thermoelectric applications, 3D printing, etc. HEAs of different forms and shapes are also available. Send us an inquiry if you are interested.

Reference:

[1] Saro San, Yang Tong, Hongbin Bei, Boopathy Kombaiah, Yanwen Zhang, Wai-Yim Ching, First-principles calculation of lattice distortions in four single phase high entropy alloys with experimental validation, Materials & Design, Volume 209, 2021, 110071, ISSN 0264-1275, https://doi.org/10.1016/j.matdes.2021.110071.

[2] Shafeie, Samrand & Guo, Sheng. (2020). Benefits of the Selection and Use of High Entropy Alloys for High-Temperature Thermoelectric Applications. 10.1201/9780367374426-16.

[3] Zeng, Minxiang & Zavanelli, Duncan & Chen, Jiahao & Saeidi-Javash, Mortaza & Du, Yipu & LeBlanc, Saniya & Snyder, G. & Zhang, Yanliang. (2021). Printing thermoelectric inks toward next-generation energy and thermal devices. Chemical Society Reviews. 51. 10.1039/D1CS00490E.