- Products

- Categories

- Blog

- Podcast

- Application

- Document

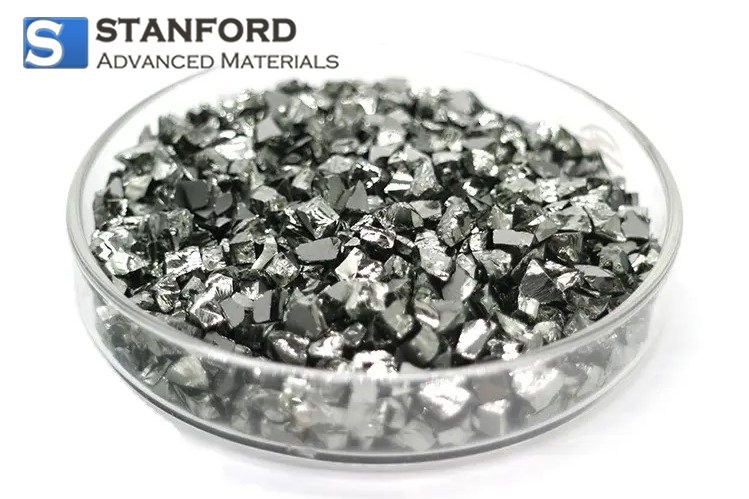

VD0622 Copper Germanium (Cu/Ge) Evaporation Materials

| Catalog No. | VD0622 |

| Material | Copper Germanium (Cu/Ge) |

| Purity | 99.9% ~ 99.999% |

| Shape | Powder/ Granule/ Custom-made |

Copper Germanium (Cu/Ge) Evaporation Materials are utilized in vacuum deposition processes, composed of copper and germanium alloys, offering tailored electrical and thermal properties for thin-film applications. Stanford Advanced Materials (SAM) specializes in producing high-purity Copper Germanium (Cu/Ge) Evaporation Materials.

Related products: Copper (Cu) Evaporation Materials, Germanium (Ge) Evaporation Materials

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!