Spherical Fe-based Powder FeCrMoWMnSiBC Description

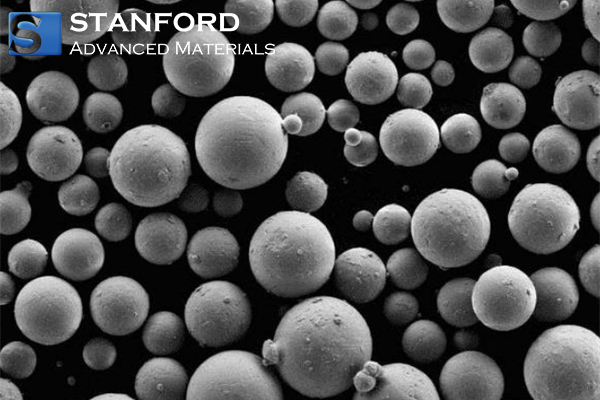

Spherical Fe-based Powder FeCrMoWMnSiBC is a type of bulk metallic glass (BMG) alloy available in powder form. The spherical shape of the powder particles is particularly beneficial for AM and PM processes, offering improved flowability and packing density. Spherical Fe-based Powder FeCrMoWMnSiBC provides advantages in terms of uniformity, flowability, and ease of use in powder metallurgy processes, such as additive manufacturing and powder injection molding.

FeZrSiCu BMGs are known for their exceptional strength, high elastic limit, corrosion resistance, and wear resistance, making them attractive for various applications including structural materials, sporting goods, medical devices, and components in the aerospace and automotive industries. The specific properties of a BMG can be tailored by adjusting the composition and processing conditions, making them highly versatile materials for engineering applications.

Spherical Fe-based Powder FeCrMoWMnSiBC Specifications

|

MGs

|

FeCrMoWMnSiBC

|

|

Laser Power (W)

|

60-420

|

|

Scan Speed (mm/s)

|

1200-3400

|

|

Hatch Spacing (μm)

|

95

|

|

Powder Size (μm)

|

15-53

|

|

Layer Thickness (μm)

|

30

|

|

Pores/Porosity (%)

|

√

|

|

Cracks

|

√

|

|

Maximum Density (%)

|

95

|

Spherical Fe-based Powder FeCrMoWMnSiBC Applications

- Additive Manufacturing (3D Printing): Spherical Fe-based powders are ideal for use in metal additive manufacturing processes, such as selective laser melting (SLM) or electron beam melting (EBM), to produce complex parts with high precision. The alloy's composition can be tailored to achieve desired mechanical properties, making it suitable for critical components in aerospace, automotive, and tooling applications.

- Powder Metallurgy: In PM, these powders are used to manufacture high-performance parts through processes like metal injection molding (MIM) or hot isostatic pressing (HIP). The components produced can have superior mechanical properties and are used in industries where high wear resistance and strength are required, such as in the production of gears, bearings, and cutting tools.

- Wear-Resistant Coatings: The high hardness and wear resistance of FeCrMoWMnSiBC alloys make them suitable for creating wear-resistant coatings on various substrates. These coatings can significantly enhance the lifespan of parts used in mining, oil and gas, and heavy machinery by protecting them from abrasion, erosion, and corrosion.

- Tooling and Die Applications: Due to their excellent wear resistance and toughness, these alloys are used in the manufacturing of tools and dies. This includes applications like injection molds, stamping dies, and extrusion dies, where the material's properties can lead to longer tool life and reduced maintenance costs.

- Automotive Components: In the automotive industry, parts made from FeCrMoWMnSiBC powders can be used in powertrain components, transmission parts, and other areas requiring high strength and wear resistance to enhance performance and durability.

- Aerospace Applications: The combination of high strength, toughness, and thermal stability makes these alloys suitable for aerospace applications, including turbine parts, structural components, and landing gear parts, where reliability and performance at elevated temperatures are crucial.

Spherical Fe-based Powder FeCrMoWMnSiBC Packaging

Our Spherical Fe-based Powder FeCrMoWMnSiBC is carefully handled during storage and transportation to preserve the quality of our product in its original condition.