- Products

- Categories

- Blog

- Podcast

- Application

- Document

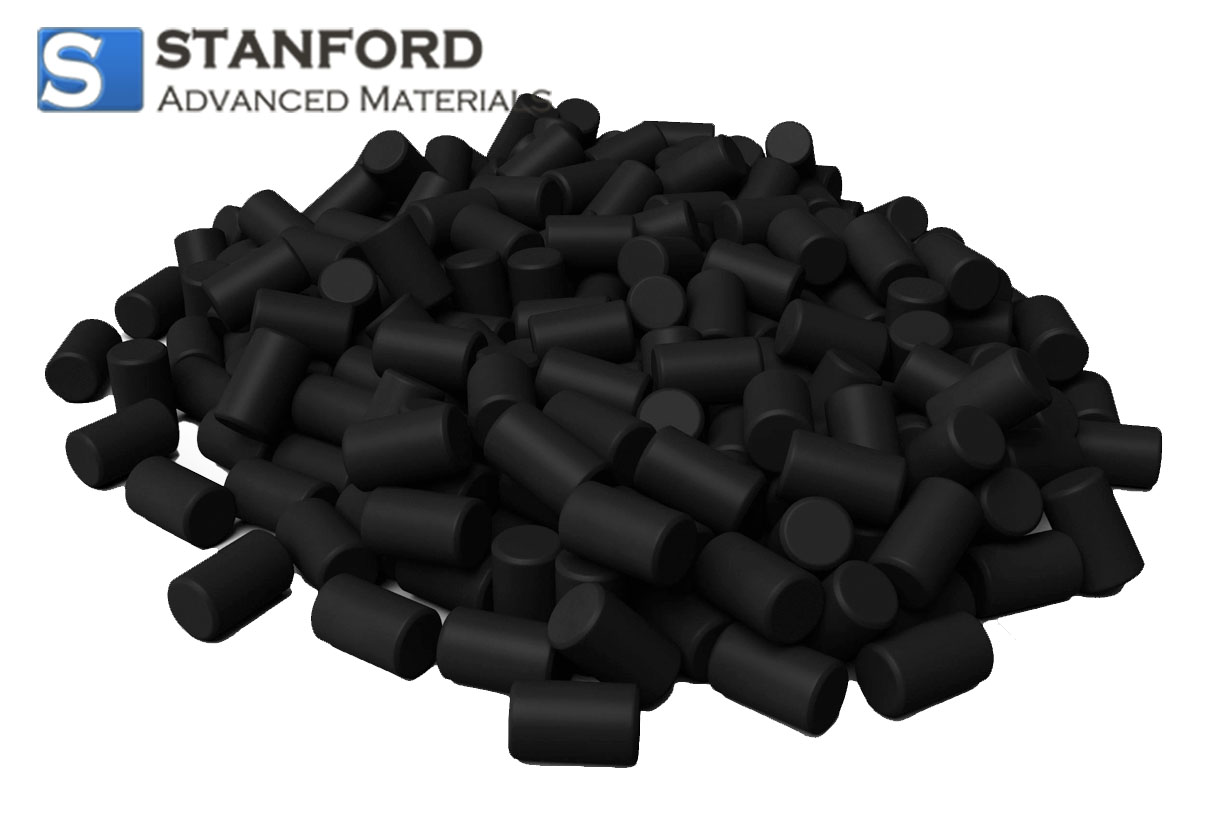

SV3689 Epoxy Molding Compounds (EM-200)

| Catalog No. | SV3689 |

| Material | EMC |

| Density | 1.9~2.1 (g/cm3) |

| Water absorption | ≤20 mg (1d/23℃) |

| Appearance | Black Cylinder |

Epoxy Molding Compounds (EM-200) are plastic with a high tracking resistance index. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Epoxy Molding Compounds (EM-200).

Related products: Nylon Thermoplastic Powders, Nylon Hose, Nylon Cable Waterproof Gland

INQUIRY

Add to Inquiry List

Description

Specification

LATEST RECOMMENDED

SV0138 Tungsten Silver Composite (W-Ag Composite)

NN0261 Nano Silver Powder (Ag 50nm) (CAS No. 7440-22-4)

NN0262 Nano Silver Powder (Ag 80nm) (CAS No. 7440-22-4)

VD0579 Silver (Ag) Evaporation Materials

CY1026 Silver (Ag) Catalyst (Organo-metallic Catalyst)

CY1328 Silver Methanesulphonate (AgCH3SO3) Powder (CAS No.2386-52-9)

CY1329 Silver Trifluoromethanesulfonate (AgCF3SO3) Powder (CAS No.2923-28-6)

imide.jpeg)

CY1330 Silver Bis(trifluoromethanesulfonyl)imide Powder (CAS No.189114-61-2)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!