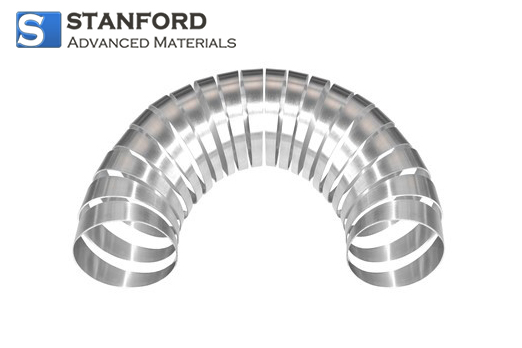

C65100 Low Silicon Bronze Wire Description

C65100 Low Silicon Bronze Wire is a robust and versatile alloy wire that excels in environments demanding high strength, corrosion resistance, and good formability. With its balanced mechanical properties and moderate electrical conductivity, it is an ideal choice for a wide range of applications, from marine hardware and industrial components to electrical connectors and decorative uses. The wire's durability makes it a reliable material for both functional and aesthetic applications, providing long-lasting performance and value.

C65100 Low Silicon Bronze Wire Specifications

Typical Chemical Composition (%)

|

UNS No.

|

Cu

|

Pb

|

Zn

|

Fe

|

Mn

|

Si

|

|

C65100

|

Bal.

|

≤0.05

|

≤1.5

|

≤0.8

|

≤0.7

|

0.8-2.0

|

Product Properties

|

Shape

|

Wire

|

|

Standard

|

ASTM B99

|

|

Principal Element

|

Cu, Si

|

|

Melting Point (℃)

|

1032 - 1060

|

|

Density (g/cm3)

|

8.75

|

|

Tensile Strength (N/mm²)

|

380

|

|

Yield Strength (N/mm²)

|

140

|

|

Thermal Conductivity (W/mK)

|

57

|

|

Electrical Resistivity μΩ.m15°C

|

14.36

|

|

Coefficient of Thermal Expansion 0-250°C

|

18

|

C65100 Low Silicon Bronze Wire Applications

- Fasteners: Ideal for bolts, wood screws, and lag screws due to high strength and toughness.

- Marine Hardware: Used in fittings, bushings, and other components exposed to saltwater.

- Electrical Components: Suitable for connectors, terminals, and electrical contacts.

- Springs and Mechanical Components: Suitable for applications needing good fatigue endurance.

C65100 Low Silicon Bronze Wire Packaging

Our C65100 Low Silicon Bronze Wire is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

FAQs

Q1: 1. What is C65100 Low Silicon Bronze Wire?

C65100 Low Silicon Bronze Wire is a copper-based alloy wire containing approximately 1.0-1.5% silicon and trace amounts of manganese, zinc, and iron. It is known for its excellent corrosion resistance, strength, ductility, and good electrical conductivity.

Q2: What are the key benefits of using C65100 Low Silicon Bronze Wire?

The wire offers several benefits, including superior corrosion resistance in marine and industrial environments, high mechanical strength, good ductility for easy forming, moderate electrical conductivity, and excellent wear resistance, making it ideal for diverse applications.

Q3: What are the common applications for C65100 Low Silicon Bronze Wire?

Common applications include electrical connectors and contacts, marine hardware, springs, fasteners, artistic sculptures, musical instrument strings, and other applications where strength, flexibility, and corrosion resistance are required.

Q4: How does C65100 Low Silicon Bronze Wire perform in marine environments?

C65100 Low Silicon Bronze Wire is highly resistant to corrosion from seawater and other harsh marine conditions, making it an excellent choice for marine hardware, rigging, and components exposed to saltwater.

Specification

Typical Chemical Composition (%)

|

UNS No.

|

Cu

|

Pb

|

Zn

|

Fe

|

Mn

|

Si

|

|

C65100

|

Bal.

|

≤0.05

|

≤1.5

|

≤0.8

|

≤0.7

|

0.8-2.0

|

Product Properties

|

Shape

|

Wire

|

|

Standard

|

ASTM B99

|

|

Principal Element

|

Cu, Si

|

|

Melting Point (℃)

|

1032 - 1060

|

|

Density (g/cm3)

|

8.75

|

|

Tensile Strength (N/mm²)

|

380

|

|

Yield Strength (N/mm²)

|

140

|

|

Thermal Conductivity (W/mK)

|

57

|

|

Electrical Resistivity μΩ.m15°C

|

14.36

|

|

Coefficient of Thermal Expansion 0-250°C

|

18

|