- Products

- Categories

- Blog

- Podcast

- Application

- Document

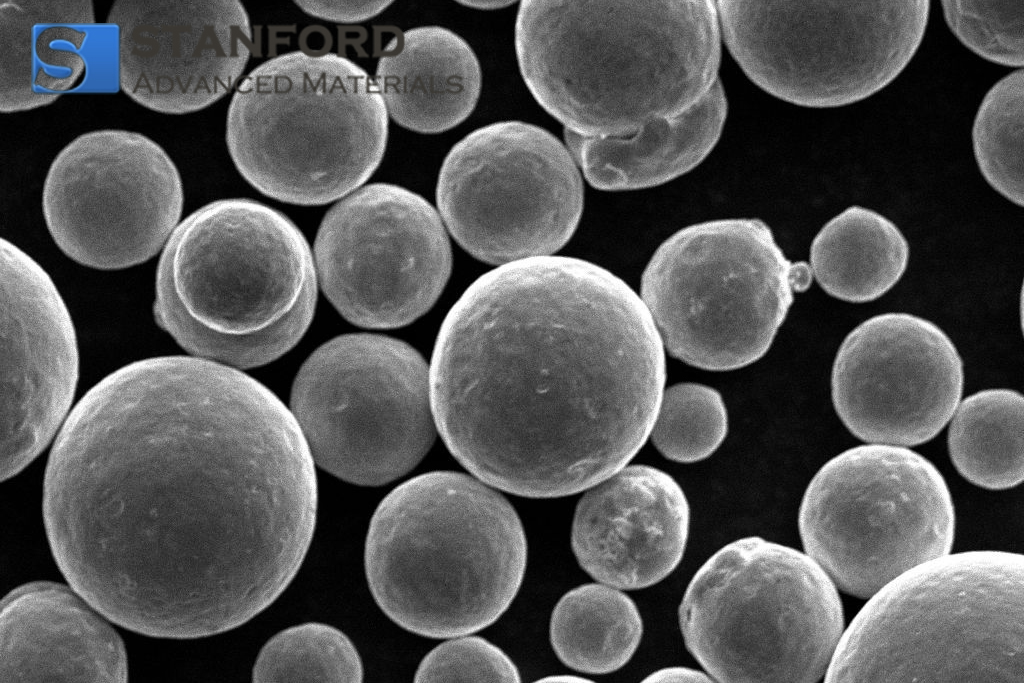

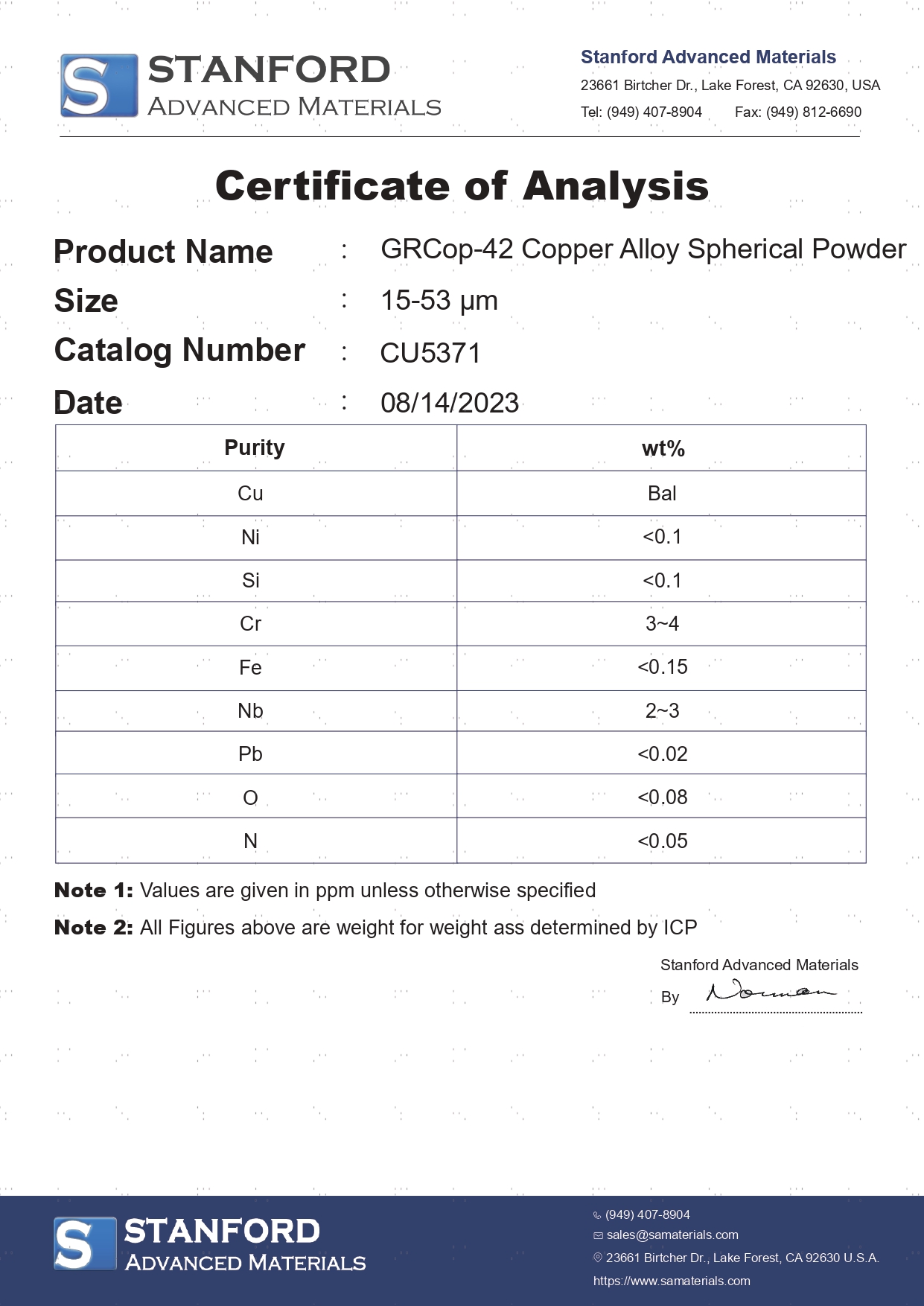

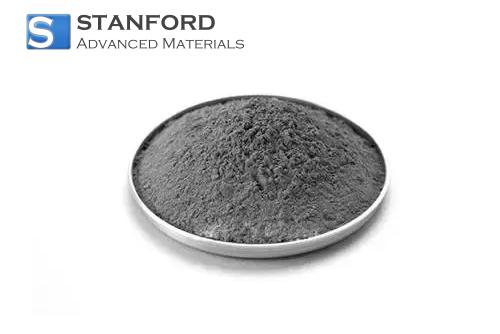

CU5371 GRCop-42 Copper Alloy Spherical Powder, CuCrNb

| Catalog No. | CU5371 |

| Compositions | CuCrNb |

| Shape | Spherical Powder |

| Density | 8.79g/cm3 |

| Particle Size | 15 to 45μm |

GRCop-42 Copper Alloy Spherical Powder is developed to additively manufacture parts in need of high-strength dispersion and high conductivity. Stanford Advanced Materials (SAM) provides Copper-based Alloy Spherical Powder of exceptional quality at highly competitive prices.

Related products: Spherical Bronze Alloy Powder CuSn10, CuCrZr High-Entropy Alloy (HEA) Spherical Powder, Copper Chromium Nanopowder, CuCr

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!