Elasticity, Stress, and Strain

What Is Elasticity

Elasticity refers to the ability of a material to undergo deformation (stretching, compressing, or bending) when subjected to an external force, and then return to its original shape when the force is removed. Essentially, elastic materials "bounce back" after being stretched or compressed. The extent to which a material can return to its original form without permanent deformation is determined by its elastic limit, beyond which the material will permanently deform or break.

Elasticity, Stress, and Strain

To understand elasticity, it’s essential to understand stress and strain, two related concepts.

· Stress is the force applied to a material per unit area, often measured in pascals (Pa) or pounds per square inch (psi). It can be classified into types like tensile stress (pulling), compressive stress (pushing), or shear stress (sliding forces).

· Strain is the result of stress, representing the deformation that occurs in a material when stress is applied. It is a dimensionless quantity, calculated as the change in length (or shape) divided by the original length or shape.

When stress is applied to an elastic material, it causes strain, but as long as the material stays within its elastic limit, the strain will be reversible. This means the material will return to its original shape once the stress is removed.

The relationship between stress and strain for elastic materials is typically linear and can be described by Hooke’s Law, which states that the amount of strain is directly proportional to the applied stress, provided the material remains within the elastic limit.

Common Elastic Materials

Various materials exhibit elastic behavior to varying degrees, and the most common examples include:

· Rubber: Known for its high elasticity, rubber can stretch significantly and return to its original shape when the force is released. It's widely used in products like tires, seals, and elastomers.

· Steel: Steel is a strong, highly elastic material that deforms only slightly under large loads, making it ideal for structural applications like bridges and buildings.

· Wood: Wood is elastic to a certain degree, allowing it to bend under pressure without breaking, especially when used in beams and planks.

· Concrete: While concrete is not highly elastic, it has enough elasticity for certain uses in construction, particularly when combined with steel reinforcement (reinforced concrete).

· Polymers: Many polymers, like nylon and polyethylene, show significant elasticity, making them ideal for flexible packaging, textiles, and medical applications.

Nitinol: A Smart Elastic Material

One of the most fascinating examples of elasticity is Nitinol, a type of shape-memory alloy that exhibits unique elastic properties. Nitinol is made primarily of nickel and titanium and can "remember" its original shape.

· Shape Memory Effect: Nitinol can be deformed at one temperature and, upon heating, will return to its original shape. This property is due to a phase change that occurs at a specific temperature, allowing the material to "snap back" to its predetermined form.

· Superelasticity: In addition to the shape-memory effect, Nitinol also exhibits superelasticity. This means that Nitinol can undergo significant deformation under stress and still return to its original shape without permanent deformation, even when the stress exceeds the material's normal elastic limit. Superelasticity is particularly useful in medical devices like stents, eyeglass frames, and actuators.

Nitinol’s combination of high elasticity, shape-memory behavior, and superelasticity has made it a revolutionary material in fields such as biomedical engineering, aerospace, and robotics.

Frequently Asked Questions

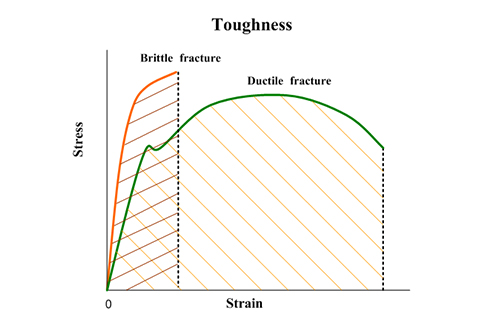

What is the difference between elasticity and plasticity?

Elasticity refers to the ability of a material to return to its original shape after deformation, while plasticity refers to the ability to undergo permanent deformation without breaking. Materials that are elastic will return to their original shape, while materials that are plastic will not.

Can all materials be considered elastic?

No, not all materials are elastic. Materials that exhibit elasticity can return to their original shape after deformation. Materials like glass, ceramics, and brittle metals may break or fracture rather than return to their original shape, making them brittle rather than elastic.

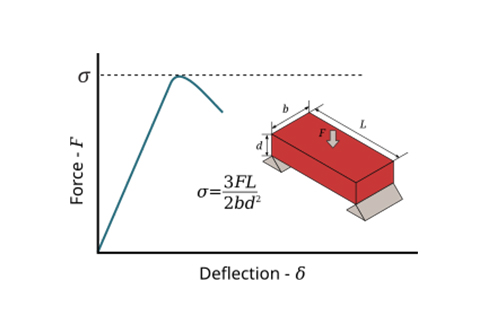

How is elasticity measured?

Elasticity is typically measured by the elastic modulus or Young's modulus, which quantifies the stiffness of a material. It is determined by dividing the stress applied to a material by the resulting strain.

Why is Nitinol used in medical devices?

Nitinol is used in medical devices due to its superelastic and shape-memory properties. These allow it to function in dynamic environments where flexibility and the ability to return to a predefined shape are crucial, such as in stents, guidewires, and other surgical tools.

How does temperature affect elasticity?

For many materials, elasticity can change with temperature. As temperature increases, the material may become more flexible or, in some cases, lose its elastic properties. For instance, Nitinol becomes more elastic at certain temperatures due to its phase change, while many metals like steel become less elastic at high temperatures.