SAM Launches Tantalum Marker Bands for the Medical Industry

Tantalum Marker Bands for the Medical Industry

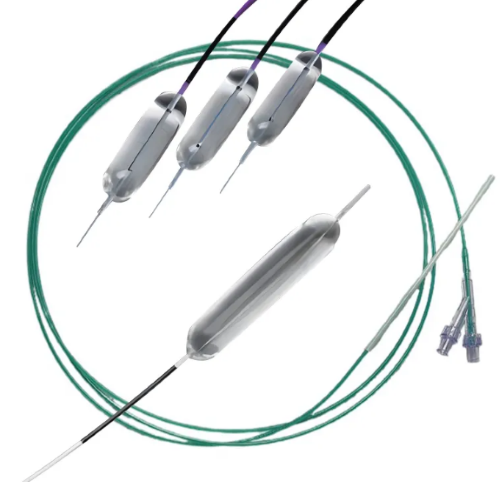

Stanford Advanced Materials (SAM), the leading materials supplier, is proud to introduce custom manufactured tantalum marker bands for the medical industry. Radiopaque marker bands are thin-walled metal tubes positioned at specific locations on a catheter for enhanced visibility under an x-ray fluoroscope.

Molly Wang from Stanford Advanced Materials (SAM) said, “Marker bands are currently made of high-density metals, such as platinum and gold. These precious metals are scarce, consequently raising the cost of manufacturing- with recent quotes up to $56/g for platinum.

Tantalum Marker Bands VS Platinum Marker Bands

Tantalum, on the other hand, is more economical than platinum, but it is problematic to manufacture. Therefore although it is a premium substitute for platinum, it has been traditionally overlooked because of the difficulty it poses during the manufacturing process.

SAM has now resolved this issue, consequently offering tantalum marker bands that can achieve the same result as platinum or other marker bands but for a fraction of the cost. The near future will see the eventual replacement of platinum marker bands, as tantalum takes prominence”.

Tantalum Marker Bands Benefits

Marker bands help with the guidance and placement of catheters during medical procedures, in particular where radiopacity is required. SAMs’ marker bands are manufactured with very tight control of dimensions and without burrs.

Tantalum Marker Bands for the Medical Industry

Why Choose SAM?

Years of industry experience and knowledge have enabled them to produce tantalum marker bands with the tightest tolerances, the thinnest walls, and the best surface and edge conditions in the medical device industry.

Tantalum marker bands are fabricated according to customer specifications in a variety of diameters. SAM has a variety of sizes of tantalum maker bands in stock for immediate needs.

Further reading:

Application of Tantalum Marker Band in Medical Devices