- Products

- Categories

- Blog

- Podcast

- Application

- Document

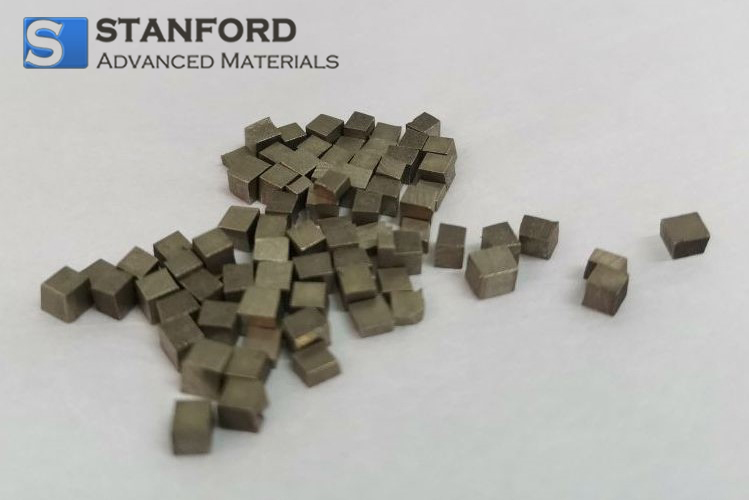

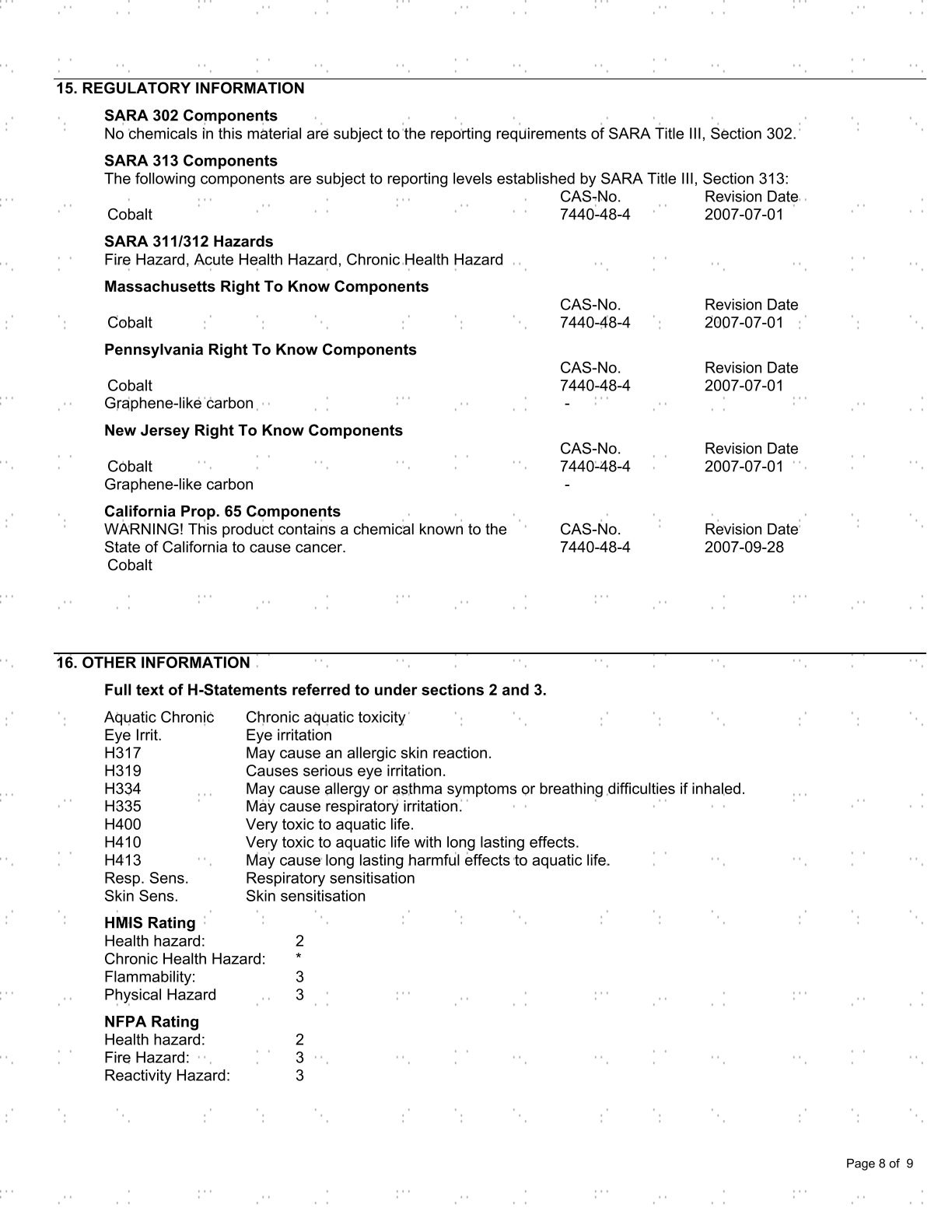

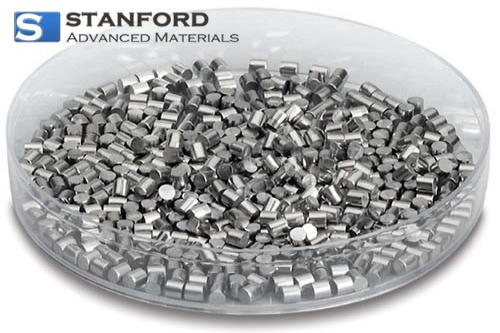

VD0543 Cobalt (Co) Evaporation Materials

| Catalog No. | VD0543 |

| Material | Cobalt (Co) |

| Purity | 99.9% ~ 99.99% |

| Shape | Granule/ Custom-made |

| MSDS/SDS |

Stanford Advanced Materials (SAM) is a leading manufacturer and supplier of high purity Cobalt Evaporation Materials and a wide variety of evaporation materials. We offer our evaporation materials in powder and granule form. Customized forms are also available upon request.

Related products: Antimony (Sb) Evaporation Materials, Aluminum (Al) Evaporation Materials

LATEST RECOMMENDED

.jpg)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!