- Products

- Categories

- Blog

- Podcast

- Application

- Document

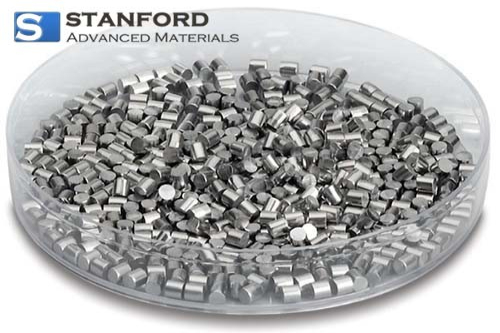

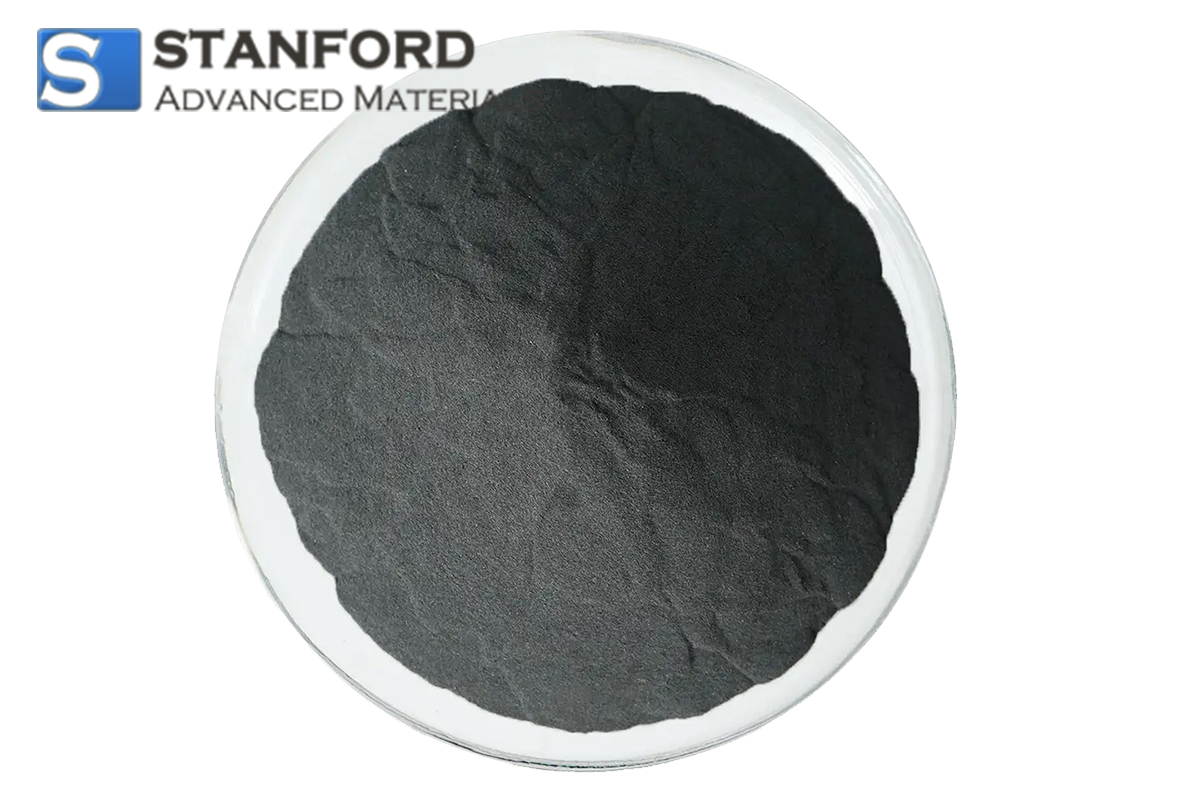

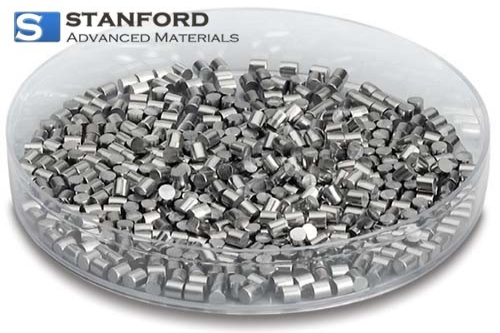

VD0612 Cobalt Chromium (Co/Cr) Evaporation Materials

| Catalog No. | VD0612 |

| Material | Cobalt Chromium (Co/Cr) |

| Purity | 99.9% ~ 99.95% |

| Shape | Powder/ Granule/ Custom-made |

Cobalt Chromium Evaporation Materials provided by Stanford Advanced Materials, composed of cobalt and chromium, are ideal for thin-film deposition due to their high melting points, uniform evaporation rates, and corrosion resistance, enhancing the performance and durability of various products.

Related products: Antimony (Sb) Evaporation Materials, Barium (Ba) Evaporation Materials

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!