VD0606 Chromium Copper (Cr/Cu) Evaporation Materials

| Catalog No. | VD0606 |

| Material | Chromium Copper (Cr/Cu) |

| Purity | 99.9% ~ 99.95% |

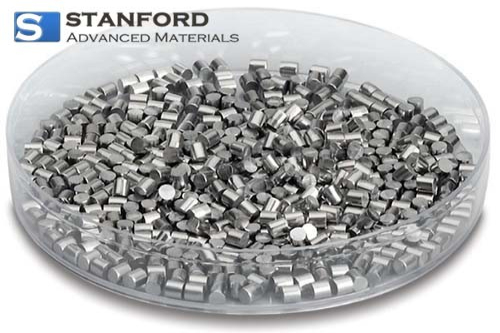

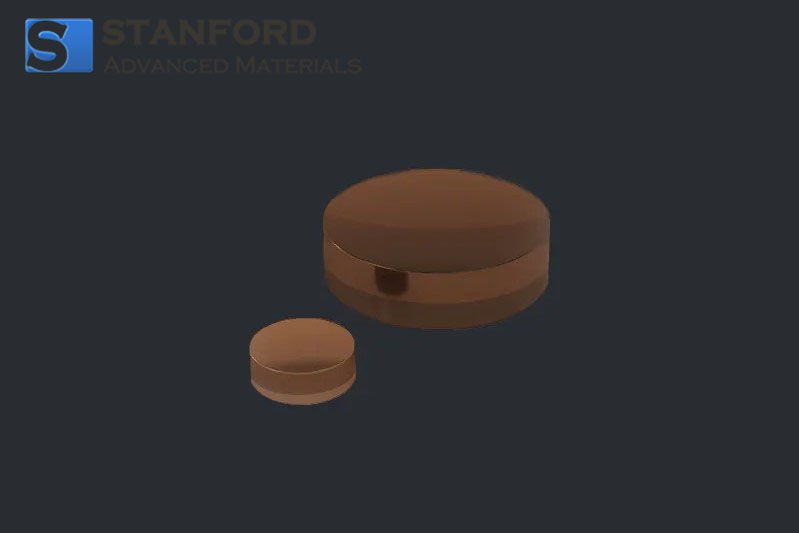

| Shape | Powder/ Granule/ Custom-made |

Chromium Copper Evaporation Materials provided by Stanford Advanced Materials, renowned for their exceptional conductivity and durability, are ideal for depositing uniform and defect-free thin films in a range of electronic applications, ensuring high performance and reliability.

Related products: Antimony (Sb) Evaporation Materials, Barium (Ba) Evaporation Materials

Description

Chromium Copper Evaporation Materials possess several notable properties that make them suitable for a wide range of applications. They exhibit excellent conductivity, which is crucial for electronic applications where efficient charge transport is required. This high conductivity ensures that the deposited thin films have low electrical resistance, enhancing the performance of electronic devices. Furthermore, Chromium Copper Evaporation Materials possess high thermal stability, allowing them to withstand the high temperatures encountered during evaporation processes. This ensures stable and reliable evaporation, resulting in thin films with uniform thickness and minimal defects.

Additionally, these materials demonstrate good adhesion and wettability, ensuring strong bonds and smooth surfaces on various substrates. This property is crucial for achieving durable and reliable thin-film coatings. Chromium Copper Evaporation Materials also exhibit good corrosion resistance, making them suitable for applications where the coating needs to withstand harsh environmental conditions.

Specification

|

Material |

Chromium Copper |

|

Color/Appearance |

Coppery Golden Metallic |

|

Melting Point (°C) |

1070 |

|

Density (g/cm3) |

8.89 |

|

Purity |

99.9% |

Applications

Chromium Copper Evaporation Materials have a diverse range of applications across various industries. In the electronics sector, they are widely used for depositing thin films in the manufacturing of semiconductors, capacitors, resistors, and other electronic components. The exceptional conductivity of these materials ensures efficient charge transport, crucial for high-performance electronic devices.

Furthermore, their corrosion resistance property makes Chromium Copper Evaporation Materials suitable for use in harsh environments, such as in automotive and aerospace applications where coatings need to withstand extreme conditions.

Additionally, their good adhesion and wettability characteristics allow them to be used in the production of optical coatings, enhancing the reflectivity and durability of lenses and mirrors. Chromium Copper Evaporation Materials are also employed in the deposition of decorative coatings, providing a unique and appealing visual effect on various surfaces.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!