- Products

- Categories

- Blog

- Podcast

- Application

- Document

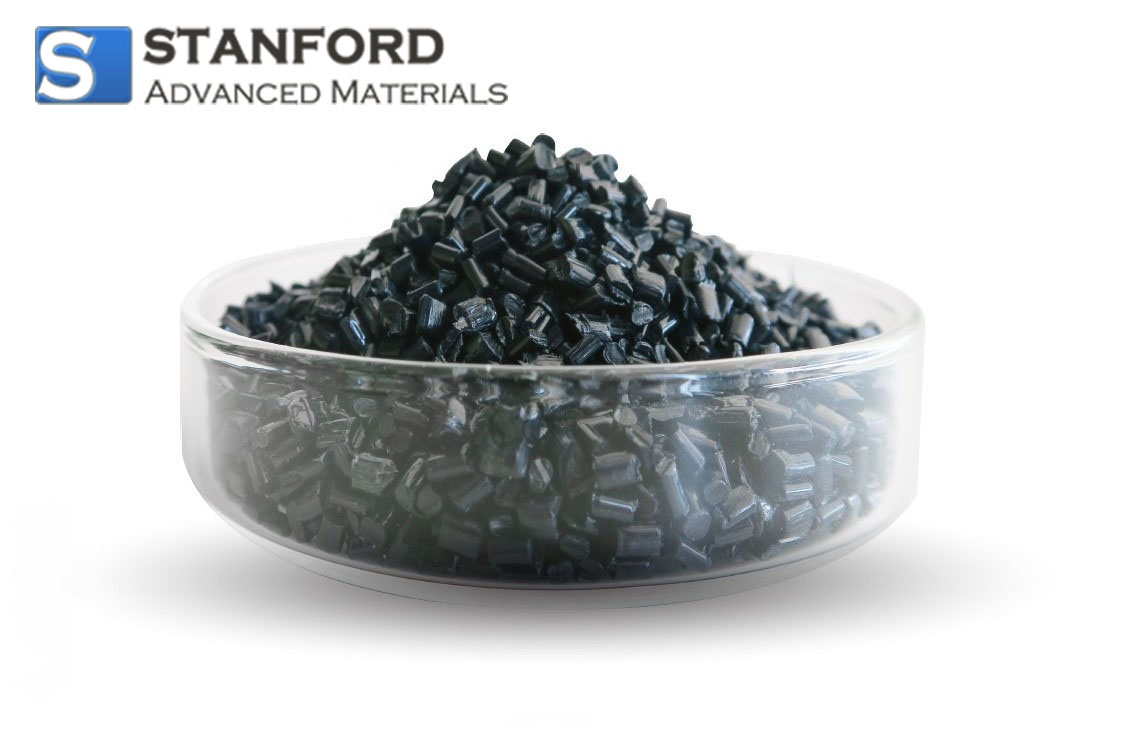

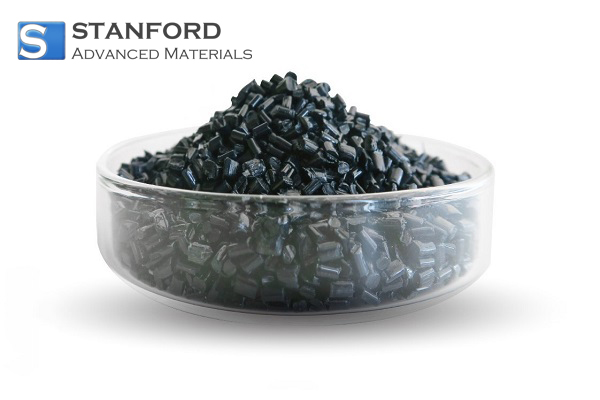

MB4964 Carbon Crystal Heat Insulation Masterbatch

| Catalog No. | MB4964 |

| Appearance | Black particles |

| Material | Nano carbon crystal |

| Carrier Material | PET, PE, PC, PMMA, etc. |

| Melting Point | 120-270℃ |

| Infrared Blocking Band (nm) | 780~2500 |

Carbon Crystal Heat Insulation Masterbatch is made by mixing nano-insulation powder with PET, PP, PE, and other plastic chips through nano-filling technology. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Masterbatches.

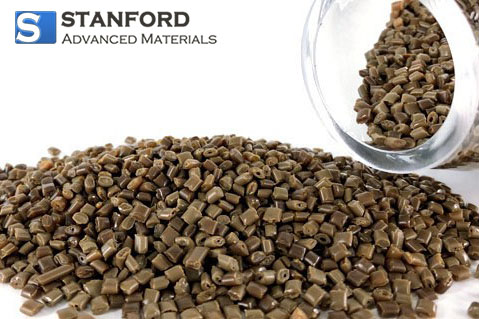

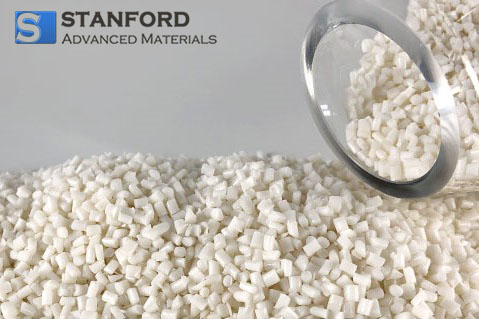

Related products: High Transparency Heat Insulation Masterbatch, Low Transparency Heat Insulation Masterbatch

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!