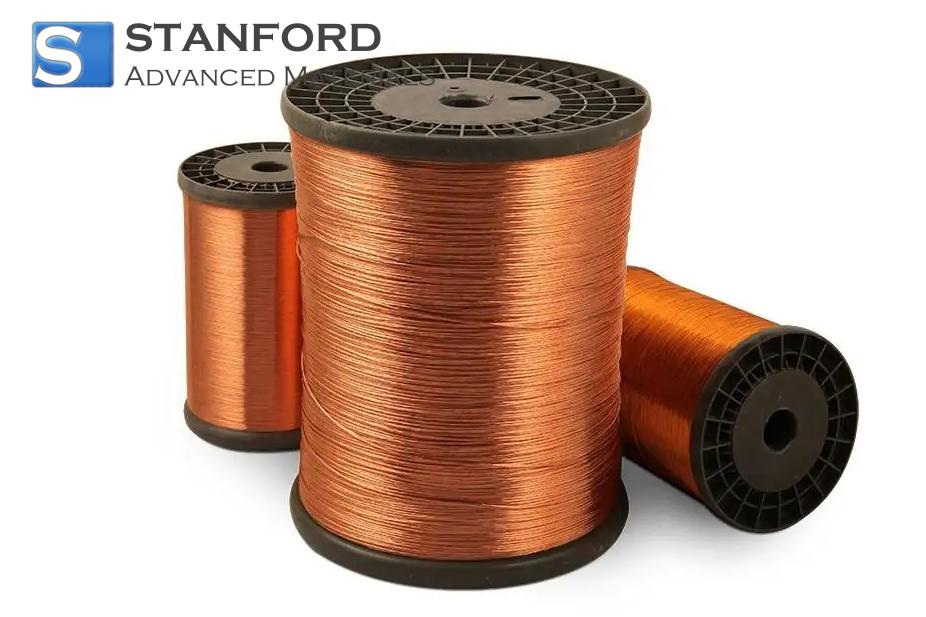

C19160 Leaded Nickel Copper Wire Description

C19160 Leaded Nickel Copper Wire is a high-performance copper alloy known for its excellent machinability, good thermal and electrical conductivity, and enhanced strength compared to pure copper. The nickel and phosphorus in the alloy combine to form nickel phosphate, which dissolves in the copper on heating to a suitable temperature, and can be retained by quenching. Subsequent aging will precipitate the nickel phosphate from solid solution in a highly dispersed manner thereby creating a remarkable hardening and strengthening effect with excellent stress relaxation properties. Subsequent cold working increases the strength still further.

C19160 Leaded Nickel Copper Wire Specifications

Typical Chemical Composition (%)

|

UNS No.

|

Ni

|

Pb

|

P

|

Sn

|

Zn

|

Fe

|

Cu

|

|

C19160

|

0.8-1.2

|

0.8-1.2

|

0.15-0.35

|

≤0.05

|

≤0.5

|

≤0.05

|

Bal.

|

Product Properties

|

Shape

|

Wire

|

|

Standard

|

ASTM B301, DIN 17666

|

|

Principal Element

|

Cu, Ni, Pb

|

|

Melting Point (℃)

|

1082

|

|

Density (g/cm3)

|

8.88

|

|

Modulus of elasticity

|

117 GPa

|

|

Yield strength

|

379 MPa

|

C19160 Leaded Nickel Copper Wire Applications

- Electrical Components: Used in connectors, terminals, and other parts where good conductivity is required.

- Automotive Parts: Utilized in bushings, bearings, and other high-wear components due to its machinability and wear resistance.

- Mechanical Components: Ideal for parts that require precision machining and high strength.

C19160 Leaded Nickel Copper Wire Packaging

Our C19160 Leaded Nickel Copper Wire is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

FAQs

Q1: What is C19160 Leaded Nickel Copper Wire?

C19160 is a copper alloy wire that combines copper, nickel, and lead to provide excellent machinability, good thermal and electrical conductivity, and enhanced strength compared to pure copper.

Q2: What are the main applications of C19160 Leaded Nickel Copper Wire?

It is used in electrical components (connectors, terminals), automotive parts (bushings, bearings), and mechanical components requiring precision machining, high strength, and good conductivity.

Q3: Why is lead added to C19160 Leaded Nickel Copper Wire?

Lead improves the machinability of the alloy, making it easier to cut and shape while also reducing tool wear during machining processes.

Q4: How does C19160 compare to pure copper in terms of performance?

C19160 has better machinability, higher strength, and improved wear resistance compared to pure copper, though it retains good thermal and electrical conductivity.

Specification

Typical Chemical Composition (%)

|

UNS No.

|

Ni

|

Pb

|

P

|

Sn

|

Zn

|

Fe

|

Cu

|

|

C19160

|

0.8-1.2

|

0.8-1.2

|

0.15-0.35

|

≤0.05

|

≤0.5

|

≤0.05

|

Bal.

|

Product Properties

|

Shape

|

Wire

|

|

Standard

|

ASTM B301, DIN 17666

|

|

Principal Element

|

Cu, Ni, Pb

|

|

Melting Point (℃)

|

1082

|

|

Density (g/cm3)

|

8.88

|

|

Modulus of elasticity

|

117 GPa

|

|

Yield strength

|

379 MPa

|