C18700 Leaded Copper Wire Description

C18700 Leaded Copper Wire is a versatile copper alloy known for its enhanced machinability, good conductivity, and balanced mechanical properties, making it an ideal choice for precision manufacturing applications. Its unique composition allows for easy machining without compromising on strength or performance, making it highly suitable for electrical components, automotive parts, and various industrial applications. Whether used in connectors, terminals, or machined components, C18700 offers reliability and efficiency, catering to industries that demand both quality and precision.

C18700 Leaded Copper Wire Specifications

Typical Chemical Composition (%)

|

UNS No.

|

Pb

|

Cu

|

Cu + Ag + Pb

|

|

C18700

|

0.8-1.5

|

Bal.

|

≥99.5

|

Product Properties

|

Shape

|

Wire

|

|

Standard

|

ASTM B301

|

|

Principal Element

|

Cu, Pb

|

|

Melting Point (℃)

|

953

|

|

Density (g/cm3)

|

8.89

|

|

Modulus of elasticity

|

117 GPa

|

|

Yield strength

|

379 MPa

|

C18700 Leaded Copper Wire Applications

- Electrical Components: Widely used in the manufacturing of electrical connectors, terminals, and conductive parts where excellent conductivity and precise machining are required.

- Automotive Parts: Used in automotive components such as fittings, bushings, and valve guides due to its machinability and wear resistance.

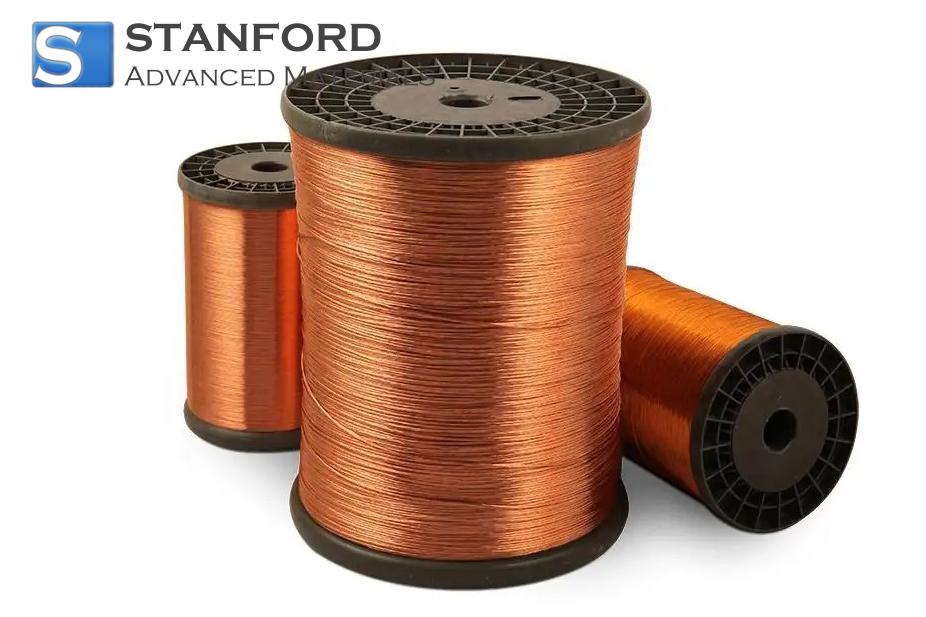

C18700 Leaded Copper Wire Packaging

Our C18700 Leaded Copper Wire is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

FAQs

Q1: What is C18700 Leaded Copper Wire?

C18700 Leaded Copper Wire is a copper alloy wire containing a small amount of lead (0.8-1.5%), which enhances its machinability while maintaining excellent electrical and thermal conductivity.

Q2: What are the main applications of C18700 Leaded Copper Wire?

It is commonly used in electrical connectors, terminals, wiring harnesses, automotive electrical systems, and other applications where high conductivity and ease of machining are crucial.

Q3: Why is lead added to C18700 Copper Wire?

Lead improves the machinability of the copper wire, allowing for smoother cutting, forming, and bending operations without compromising the wire’s conductivity and overall performance.

Q4: Is C18700 Leaded Copper Wire safe for electrical applications?

Yes, it is widely used in electrical applications due to its excellent conductivity. However, it should be used in compliance with regulations concerning lead content in electrical components, especially in environments where RoHS (Restriction of Hazardous Substances) compliance is required.

Specification

Typical Chemical Composition (%)

|

UNS No.

|

Pb

|

Cu

|

Cu + Ag + Pb

|

|

C18700

|

0.8-1.5

|

Bal.

|

≥99.5

|

Product Properties

|

Shape

|

Wire

|

|

Standard

|

ASTM B301

|

|

Principal Element

|

Cu, Pb

|

|

Melting Point (℃)

|

953

|

|

Density (g/cm3)

|

8.89

|

|

Modulus of elasticity

|

117 GPa

|

|

Yield strength

|

379 MPa

|