Indium: Element Properties and Uses

Description

Indium is a rare, soft metal with unique chemical and physical properties; it is extensively used in electronics, semiconductors, and industrial products.

Introduction to the Element

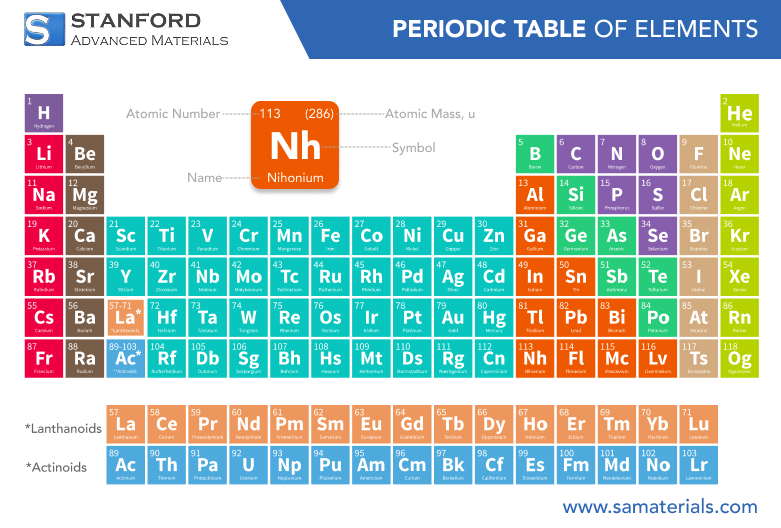

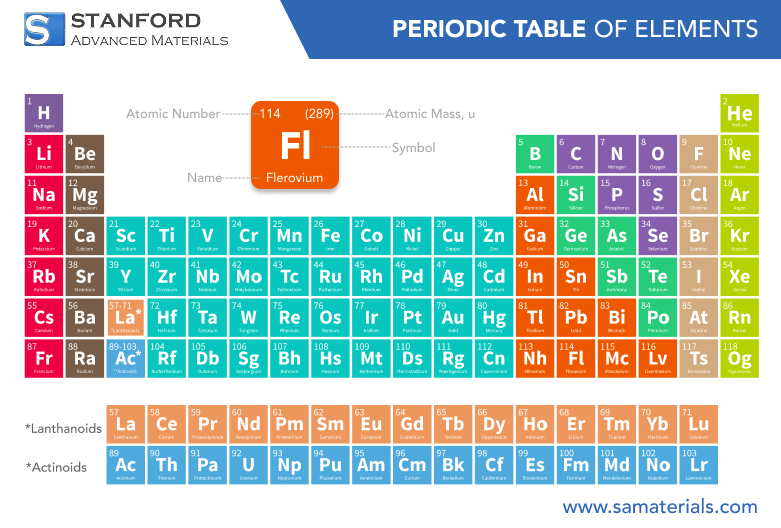

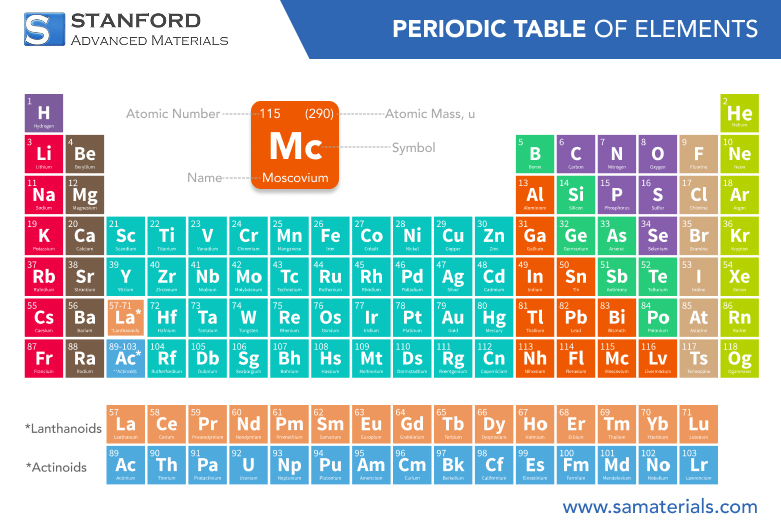

Indium, with the atomic symbol In and atomic number 49, is a post-transition metal that occupies a special place in the periodic table. Discovered in 1863 by Ferdinand Reich and Hieronymous Theodor Richter, indium is relatively scarce in the Earth's crust and is most often obtained as a byproduct during the processing of zinc ores.

Chemical Properties Description

Indium commonly displays a +3 oxidation state, forming compounds such as indium oxide (In₂O₃) and indium chloride (InCl₃) that are vital for various semiconductor and catalytic applications. In some circumstances, indium can also display a +1 oxidation state, providing chemists with additional versatility in compound synthesis.

At room temperature, indium is relatively inert due to the formation of a thin, protective oxide layer on its surface. This passivation helps prevent further oxidation when the metal is exposed to air, ensuring stability in many practical applications. However, when subjected to acidic or highly reactive environments, indium readily reacts, dissolving to form corresponding salts.

Physical Properties Data Table

Property | Value | Unit |

Atomic Number | 49 | - |

Atomic Weight | 114.82 | g/mol |

Density | 7.31 | g/cm³ |

Melting Point | 156.6 | °C |

Boiling Point | 2072 | °C |

Electrical Conductivity | 1.34e6 | S/m |

Crystal Structure | Tetragonal | - |

For more information, please check Stanford Advanced Materials (SAM).

Preparation Methods

The extraction and purification of indium require specialized preparation methods due to its low natural abundance. Typically, indium is recovered as a byproduct from zinc ore processing, where it is present in minute quantities. The primary extraction method involves hydrometallurgical processes, which start with leaching the ore using acid solutions. In addition to hydrometallurgical techniques, pyrometallurgical processes are also employed, particularly in the recycling of electronic waste and industrial scrap.

Common Uses

One of the most prominent applications is in the production of indium tin oxide (ITO), a compound that has become indispensable for manufacturing liquid crystal displays (LCDs), touch screens, and flat-panel displays. The unique combination of electrical conductivity and optical transparency in ITO makes it ideal for modern electronic devices.

Apart from its role in display technologies, indium is a key ingredient in the formulation of low melting point alloys. These alloys are extensively used in safety devices such as thermal fuses and fire detection systems, where rapid and reliable melting is required.

In the electronics manufacturing sector, indium is utilized for soldering purposes, creating secure electrical connections that enhance device durability and performance. The metal also finds application in semiconductor devices and specialized coatings designed to improve resistance to heat and corrosion.

Frequently Asked Questions

What is indium?

Indium is a rare, soft metal with the atomic number 49, known for its

distinctive chemical and physical properties that make it valuable in high-tech

applications.

How is indium extracted?

Indium is mainly extracted as a byproduct of zinc ore processing using

hydrometallurgical and pyrometallurgical methods to isolate high-purity metal.

What are the common uses of indium?

Indium is widely used in the production of indium tin oxide for displays, in

low melting point alloys for safety devices, and in various semiconductor

applications.

How do indium’s chemical properties benefit industrial applications?

Its ability to form stable compounds with a +3 oxidation state, coupled with a

protective oxide layer, makes indium ideal for producing durable and efficient

materials.

What related industrial products incorporate indium?

Products such as indium tin oxide for flat panel displays and advanced alloys

for electronic packaging and thermal management rely on indium for enhanced

performance.