What is Binder Jetting 3D Printing?

What is 3D Printing?

3D printing, also known as additive manufacturing (AM), is a new nonconventional method to produce components or products by adding materials together layer by layer. 3D printing no longer requires material subtractions to create molds or net shape. It can freely create complex, specific and unrealizable components that are not possible with traditional manufacturing. Although 3D printing is a new technology quite different from traditional manufacturing, lots of related research and papers had been published since 2014. [1] It is now entering many different industries to challenge the traditional technologies.

3D printing can be divided into two groups: one uses the fusion-based method such as Powder Bed Fusion (PBF), Directed Energy Deposition (DED); the other uses the non-fusion method such as Binder Jetting (BJ). This article will focus on binder jetting technology.

What is Binder Jetting?

Binder Jetting (BJ) is one of the main 3D printing technologies widely used. It spreads the powder into a layer on the powder bed and uses a binder, usually a polymeric liquid, to selectively join the powder into the desired layer shape. 3D geometry is built by binding layer by layer in the powder box. Remove the unused powder and you will get the printed “green” parts. These “green” parts need post-treatments such as sintering and impregnation to get the desirable properties for use.

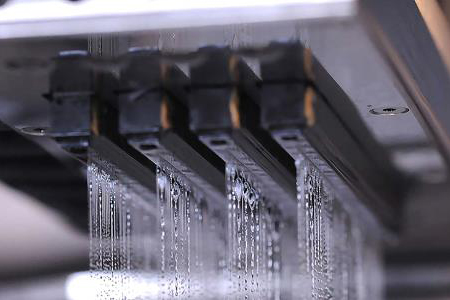

As technology improves for sintering small features, and struts, binder jetting is widely used in electrochemical energy storage, electronic devices, food technology, solid oxide fuel cells [66], molds for sand casting [67–76], waveguide circuits and antennas, concrete construction, renewable bio-based materials, ceramic scaffolds, biopolymers, sandstone production, and biomedical applications and drug delivery. [2] Figure 1[1] shows the print head for a binder jetting printer.

Detailed Procedure of Binder Jetting

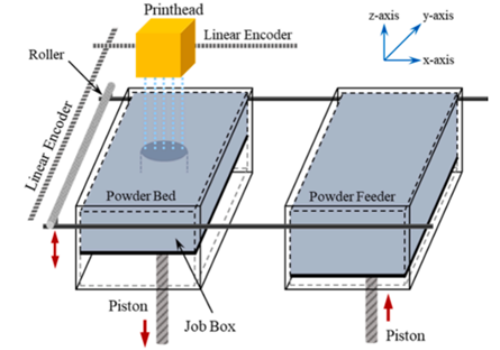

For all additive manufacturing methods, a designed/ scanned CAD model is the key element to create thin layer data for printing. The thin layer is then spread on the powder bed, usually by a counter-rolling roller with powder. Controlled by the computer, the print head sprinkles the binder (polymer) onto the layer according to the CAD model. Binder saturation should be calculated based on powder density and be input by the operator. Figure 2 shows the structure of a Binder Jetting machine for your reference.

After jetting, the binder is heated by an electrical heater in preparation for subsequent layer spreading. Maintaining a constant temperature helps maintain the quality of each layer. Curing or drying the binder is very important to prevent cracking of the powder bed or sticking powder on the roller. The piston then descends a distance of one layer, usually from 50 to 200 µm, resulting in a new layer of powder to be spread on top by the roller. Repeat the steps above until you get the “green” part.

Post Processing of Binder Jetting

After printing, post-curing is sometimes required to achieve sufficient strength for the “green” part. Take the whole powder box into an oven under 180 to 200℃ for several hours, depending on the volume and grade of the binder. Then take the “green” part out from the powder bed, which is called de-powdering. You can use a brush or a vacuum system to de-powder the product. Be careful throughout this process, because the “green” part is still less dense and held together by the binder. Another way to dry or cure is using light, and the “green” part can be removed directly from the machine.

Remove the polymeric binder by heating at about 600 ~ 700℃ after drying. Sintering or infiltration is the next step. Sintering is often used for metal powder for its low sintering temperature compared to ceramic powder. Sintering parameters are a very complicated consideration. For powders of different materials and different particle sizes, the sintering temperature, atmosphere, and holding time are all different. Sintering should be taken according to the tolerance of the material and the dimension of the final product. Infiltration usually has better accurate features than sintering, which may make warped geometries. [4]

The last step is polishing the condensed part to reduce surface roughness.

Advantages and Disadvantages for Binder Jetting

Advantages:

- Binder jetting does not fuse powder and cause it to bond. No need to worry about powder oxidation. No need for expensive sealed chambers to achieve a vacuum/ inert environment.

- The whole process is carried out at room temperature, so the final product has no residual stress.

- Its operating speed is faster than other additional manufacturing methods.

- Various types of powder can be used in binder jetting.

Disadvantages:

- The post-processing procedure is relatively complicated.

- The product surface is rougher than those obtained by other AM methods.

- Different materials need different post-processing parameters.

Powder Material Used in Bind Jetting

Binder jetting uses powder from 0.2 to 200 μm as its raw material. It is reported that 20 μm is a watershed because powder larger than 20 μm can be considered coarse powder. In theory, the finer the powder, the higher the resolution of the product produced by binder jetting. However, the fine powder is hard to spread uniformly layer by layer, that is, its flowability is low. Therefore, what diameter is best for binder jetting is still debatable.

Spherical powder such as metal, sand and ceramics is widely used in binder jetting. Spherical powder can make a homogeneous microstructure among the powder, preventing macro-voids through which binders cannot penetrate. In other words, using spherical powder can produce denser “green” components than irregular powder. Density is positively related to the strength of the component.

Further Reading: 3D Printing Powder: What is it & How is it Used?

Applications of Bind Jetting

Binder jetting has a variety of uses in the industrial, dental, medicinal, aerospace, part casting, luxury, and other industries. Binder Jetting is mainly used in structural ceramics and functional ceramics, but recently it shows good performance in biomedical engineering, represented by hydroxyapatite powder or tricalcium phosphate powder. Al2O3 spherical powder, SiO2 spherical powder and Si3N4 powder represent the structural and functional powders used in binder jetting.

For more information, please visit Stanford Advanced Materials Homepage.

Reference:

- Mostafaei, A., Elliott, A. M., Barnes, J. E., Li, F., Tan, W., Cramer, C. L., Nandwana, P., & Chmielus, M. (2021). Binder jet 3D printing—process parameters, materials, properties, modeling, and challenges (pp.2). Progress in Materials Science, 119, 100707. https://doi.org/10.1016/j.pmatsci.2020.100707

- Mostafaei, A., Elliott, A. M., Barnes, J. E., Li, F., Tan, W., Cramer, C. L., Nandwana, P., & Chmielus, M. (2021). Binder jet 3D printing—process parameters, materials, properties, modeling, and challenges (pp.6). Progress in Materials Science, 119, 100707. https://doi.org/10.1016/j.pmatsci.2020.100707

- Mostafaei, A., Elliott, A. M., Barnes, J. E., Li, F., Tan, W., Cramer, C. L., Nandwana, P., & Chmielus, M. (2021). Binder jet 3D printing—process parameters, materials, properties, modeling, and challenges (pp.7). Progress in Materials Science, 119, 100707. https://doi.org/10.1016/j.pmatsci.2020.100707

- Mostafaei, A., Elliott, A. M., Barnes, J. E., Li, F., Tan, W., Cramer, C. L., Nandwana, P., & Chmielus, M. (2021). Binder jet 3D printing—process parameters, materials, properties, modeling, and challenges (pp.9). Progress in Materials Science, 119, 100707. https://doi.org/10.1016/j.pmatsci.2020.100707

- What is binder jetting? ExOne. (n.d.). Retrieved December 19, 2022, from https://www.exone.com/en-US/Resources/case-studies/what-is-binder-jetting