- Products

- Categories

- Blog

- Podcast

- Application

- Document

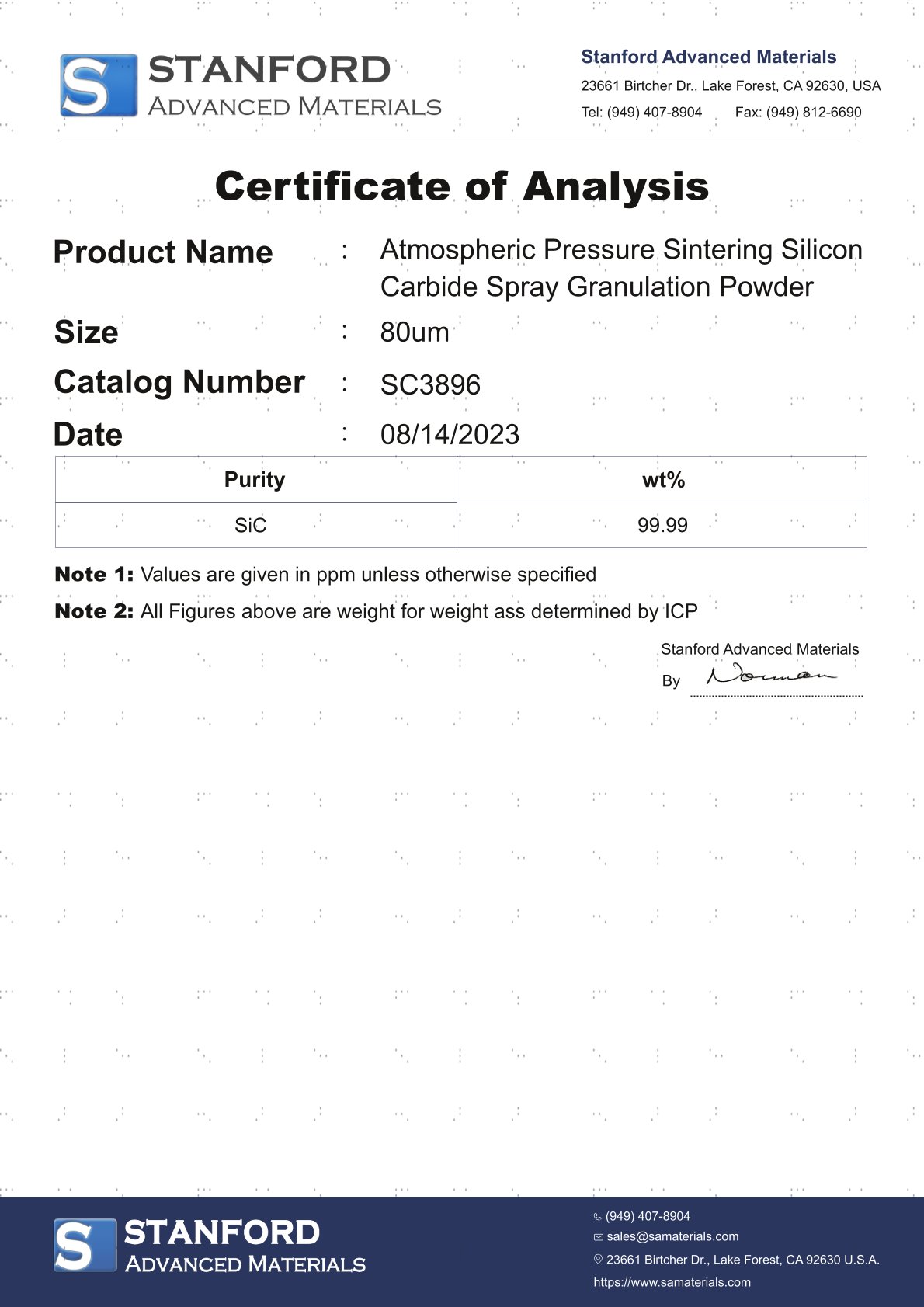

SC3896 Atmospheric Pressure Sintering Silicon Carbide Spray Granulation Powder

| Catalog No. | SC3896 |

| CAS Number | 409-21-2 |

| Molecular Formula | SiC |

| Molecular Weight | 40.1 |

| Appearance | Brown to black powder |

| Purity | >99% |

| Particle Size | 80um (D50) |

Stanford Advanced Materials (SAM) can provide silicon carbide powder series. Atmospheric Pressure Sintering Silicon Carbide Spray Granulation Powder is a type of Silicon Carbide Powders product. SAM provides Silicon Carbide Powders with high purity and competitive prices.

Related products: Green Silicon Carbide, Ready to Press Silicon Carbide Powder, Sinter Grade Silicon Carbide Powder, Black Silicon Carbide SiC

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!