Aluminum Strontium Master Alloy Description

Aluminum strontium master alloys are semi-finished products and can be formed in different shapes. They are a pre-alloyed mixture of alloying elements. They are also known as modifiers, hardeners, or grain refiners based on their applications. These master alloys are used in aluminum wrought alloys and foundry alloys for composition adjustments and structure control.

The use of strontium to “modify” the structure of hypoeutectic aluminum silicon casting alloys is an effective and widely accepted practice. Stanford Advanced Materials offers a complete range of alloys for the global aluminum industry including the Aluminum- Strontium master alloy.

Aluminum Strontium Master Alloy Specification

|

Alloy

|

Si

|

Fe

|

Ti

|

B

|

Ca

|

Mg

|

Sr

|

P

|

Ba

|

Other Single

|

Total Impurities

|

|

AlSr3.5

|

0.20%

|

0.30%

|

/

|

/

|

0.03%

|

/

|

3.2~3.8%

|

0.01%

|

/

|

0.03%

|

0.10%

|

|

AlSr5

|

0.20%

|

0.30%

|

/

|

/

|

/

|

/

|

4.0~6.0%

|

/

|

/

|

0.05%

|

0.15%

|

|

AlSr10

|

0.20%

|

0.30%

|

/

|

/

|

0.03%

|

0.05%

|

9.0~11.0%

|

0.01%

|

0.10%

|

0.05%

|

0.15%

|

|

AlSr15

|

0.20%

|

0.30%

|

/

|

/

|

0.05%

|

0.05%

|

14.0~16.0%

|

/

|

0.10%

|

0.05%

|

0.15%

|

|

AlSr20

|

0.20%

|

0.30%

|

/

|

/

|

0.05%

|

0.05%

|

18.0~22.0%

|

/

|

0.10%

|

0.05%

|

0.15%

|

|

AlSr10Ti1B0.2

|

0.20%

|

0.15%

|

0.9~1.1%

|

0.18~0.22%

|

/

|

/

|

9.0~11.0%

|

/

|

0.10%

|

0.03%

|

0.10%

|

Aluminum Strontium Master Alloy Applications

Aluminum strontium master alloys have the following applications:

- Hardeners: Used for enhancing the physical and mechanical properties of metal alloys.

- Grain Refiners: Used for controlling the dispersion of individual crystals in metals to produce a finer and more uniform grain structure.

- Modifiers & Special Alloys: Typically used to increase strength, ductility, and machinability.

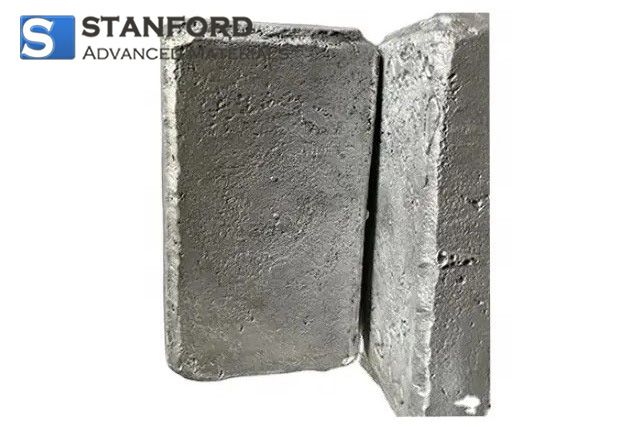

Aluminum Strontium Master Alloy Packaging

|

Ingot

|

200g/ingot or 250g/ingot

|

20kg/carton,1mt/pallet

|

|

Wire

|

Diameter 9.1-9.9mm

|

1mt/wooden box

|

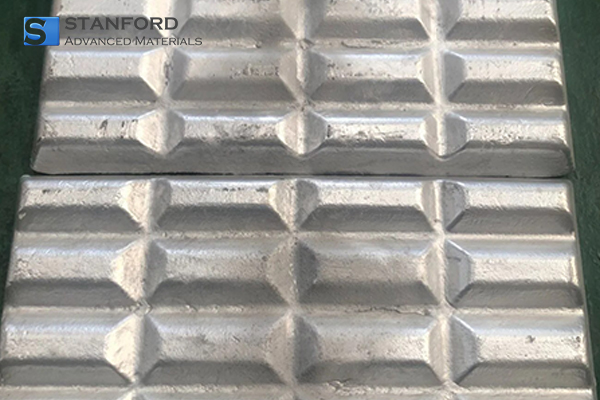

|

Waffle

|

7.5±0.5kg/waffle

|

1mt/pallet wrapped with shrunk plastic foil

|

Aluminum Strontium Master Alloy FAQs

Q1: What are the primary applications of Aluminum-Strontium Master Alloy?

Automotive: Used in engine blocks, cylinder heads, and other cast components.

Aerospace: Improves casting properties in high-performance aluminum parts.

Foundry and Casting: Refines aluminum-silicon alloys for better mechanical properties.

Industrial Equipment: Enhances durability and machinability of cast components.

Q2: What are the benefits of using Aluminum-Strontium Master Alloy?

Microstructure Modification: Refines silicon structure in aluminum-silicon alloys, reducing brittleness.

Improved Mechanical Properties: Enhances strength, ductility, and fatigue resistance.

Better Casting Quality: Reduces porosity and hot cracking during casting.

Consistent Results: Provides uniform modification in high-volume production.

Q3: How is Aluminum-Strontium Master Alloy used?

It is added to molten aluminum-silicon alloys to introduce strontium, modifying the microstructure and improving casting quality.