- Products

- Categories

- Blog

- Podcast

- Application

- Document

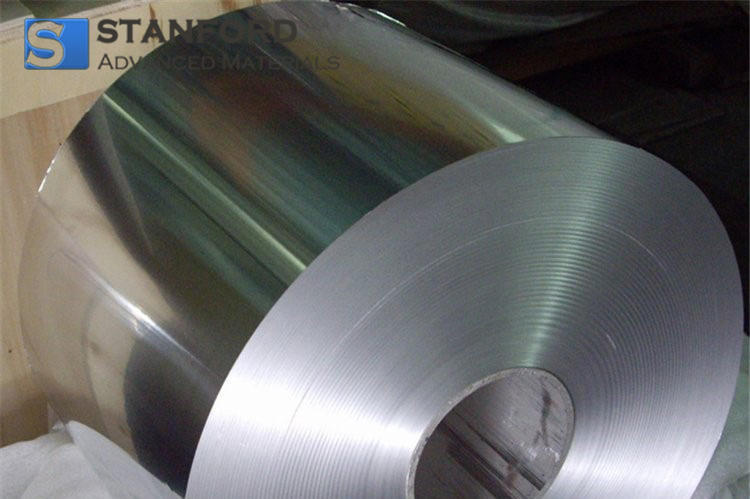

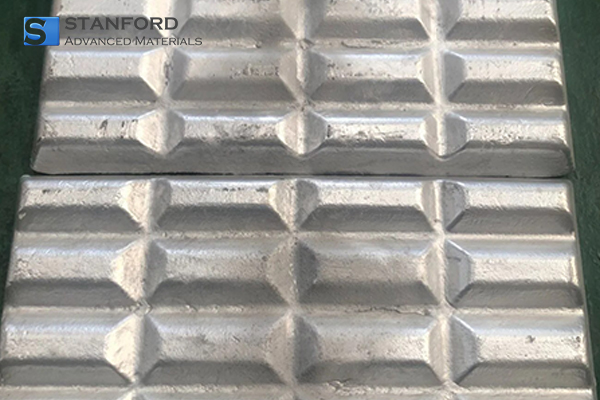

ALF1461 ALUMINUM ALLOY 1050 Foil

| Catalog No. | ALF1461 |

| Material | ALUMINUM ALLOY 1050 |

| Standard | QQA-1876, ASTM B479 |

| Thickness | 0.00018 to 0.064 in |

| Width | 0.375 to 60 in |

Aluminum Alloy 1050 Foil contains a minimum of 99.5% aluminum. Stanford Advanced Materials (SAM) supplies our customers with high-quality 1050 Aluminum Alloy Foil.

Related Products: 1100 Aluminum Alloy Foil, 1145 Aluminum Foil, 1235 Aluminum Foil, 1350 Aluminum Foil.

INQUIRY

Add to Inquiry List

Description

Specification

LATEST RECOMMENDED

SC1019 Scandium Aluminum Alloys, Aluminum Scandium Alloys

AL1091 Yttrium-Aluminum Alloy (Y-Al Alloy)

ZN1223 Zinc / Aluminum Wire (Zn/Al Wire)

LM1298 Aluminum Lithium Alloy (Al-Li Alloy)

ZN1346 Zinc Aluminum Cadmium Alloy Wire (Zn/AI/Cd Alloy Wire)

ZN1347 Zinc Aluminum Cadmium Alloy Sheet / Foil / Ribbon

AL1645 (Discontinued) Aluminum Tantalum Master Alloy

NR1745 (Discontinued) Sialon Powder (Silicon Aluminum Oxynitride) (Discontinued)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!