- Products

- Categories

- Blog

- Podcast

- Application

- Document

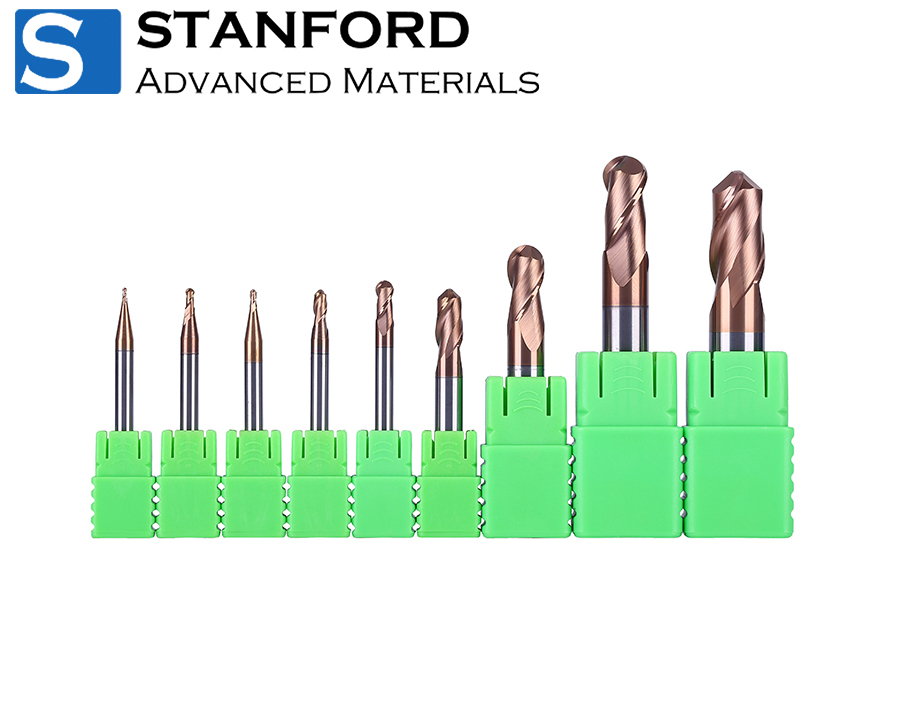

LAB4049 60HRC Carbide Ball Nose End Mill

| Catalog No. | LAB4049 |

| Model | Ball End |

| Cutting Diameter | 1-20mm |

| OAL | 50-200mm |

| Coating Material | Nano-Bronze |

60HRC Carbide Ball Nose End Mill is coated for general use on high hardness Materials up to 58-60HRC. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality 60HRC Carbide Ball Nose End Mill.

Related products: 2 Flute Long Neck Carbide Ball Nose End Mills, Corn Teeth End Mill, 55HRC Square end mill, Solid Carbide Bottom Engraving Bits

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!