301 Stainless Steel Powder Description

301 Stainless Steel Powder is a finely powdered form of stainless steel alloy 301, which is composed primarily of iron, chromium, and nickel. This powder is produced through atomization or grinding of stainless steel 301 ingots or scrap materials. It possesses excellent corrosion resistance, high strength, and good ductility, making it suitable for various applications.

301 stainless steel has a very similar content of Cr and Ni to 304 stainless steel but is still a little bit smaller. 304 stainless steel shows better resistance than 301 stainless steel due to higher Cr and Ni contents. But grade 301 has an average lower price and higher hardness than grade 304.

301 Stainless Steel Powder Specifications

|

Particle Size

|

15~45, 53-150μm, or customized

|

|

Purity

|

99.9%

|

|

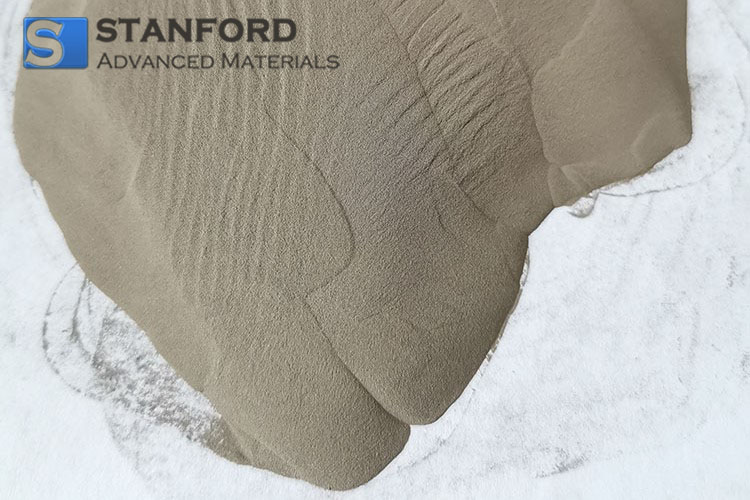

Morphology

|

spherical

|

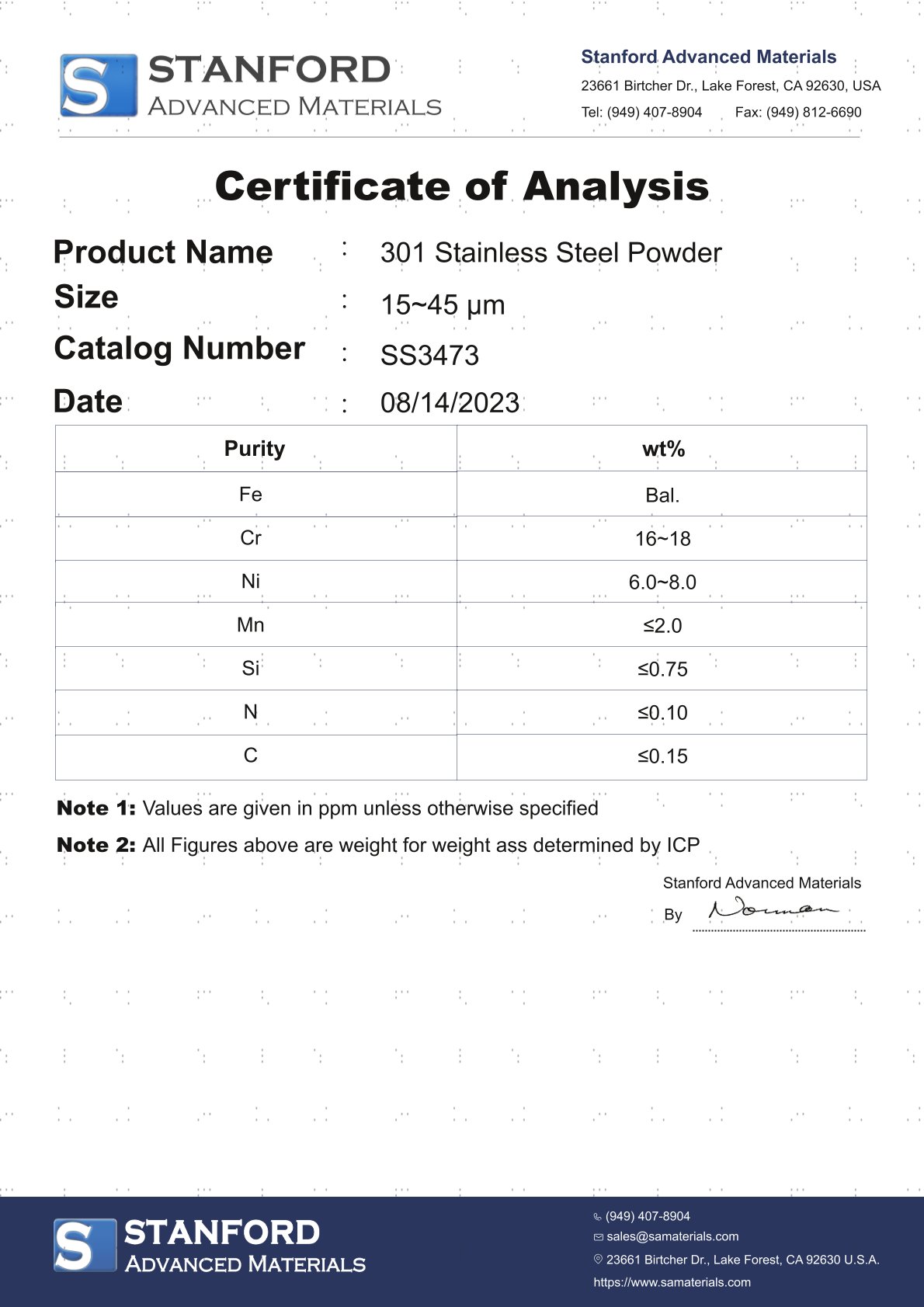

301 Stainless Steel Powder Content

|

Element

|

Fe

|

Cr

|

Ni

|

Mn

|

Si

|

N

|

C

|

|

wt%

|

Bal.

|

16~18

|

6.0~8.0

|

≤2.0

|

≤0.75

|

≤0.10

|

≤0.15

|

301 Stainless Steel Properties

|

Density (g/cm3)

|

7.88

|

|

Yield Strength (MPa)

|

276

|

|

Tensile Strength (MPa)

|

758

|

|

Tensile Modulus (GPa)

|

193

|

|

Poisson's ratio

|

0.24

|

|

Elongation at break

|

9.0%

|

301 Stainless Steel Powder Applications

- Metal Injection Molding (MIM): 301 Stainless Steel Powder is utilized in the MIM process to fabricate small and complex stainless steel components with high precision. Its fine particle size and good flowability enable the production of intricate shapes, making it suitable for industries such as automotive, aerospace, and medical.

- Powder Metallurgy (PM): The powder can be used in powder metallurgy processes such as compaction and sintering to produce stainless steel parts with excellent mechanical properties. These parts find applications in machinery, tools, and industrial equipment.

- Additive Manufacturing (AM): 301 Stainless Steel Powder can be used in additive manufacturing techniques like selective laser melting (SLM) or electron beam melting (EBM) to fabricate stainless steel parts with complex geometries. The resulting parts exhibit high strength, corrosion resistance, and dimensional accuracy.

- Stainless Steel Coatings: The powder is employed in thermal spray coatings and cold spray applications to provide a corrosion-resistant and wear-resistant layer on various substrates. It is commonly used in industries such as aerospace, oil and gas, and automotive for protecting critical components.

- Wire and Cable Industry: 301 Stainless Steel Powder is used as a feedstock material for producing stainless steel wires and cables. It provides excellent corrosion resistance and mechanical strength, making it suitable for demanding applications in electrical and communication systems.

301 Stainless Steel Powder Packaging

Our 301 Stainless Steel Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

.jpg)