- Products

- Categories

- Blog

- Podcast

- Application

- Document

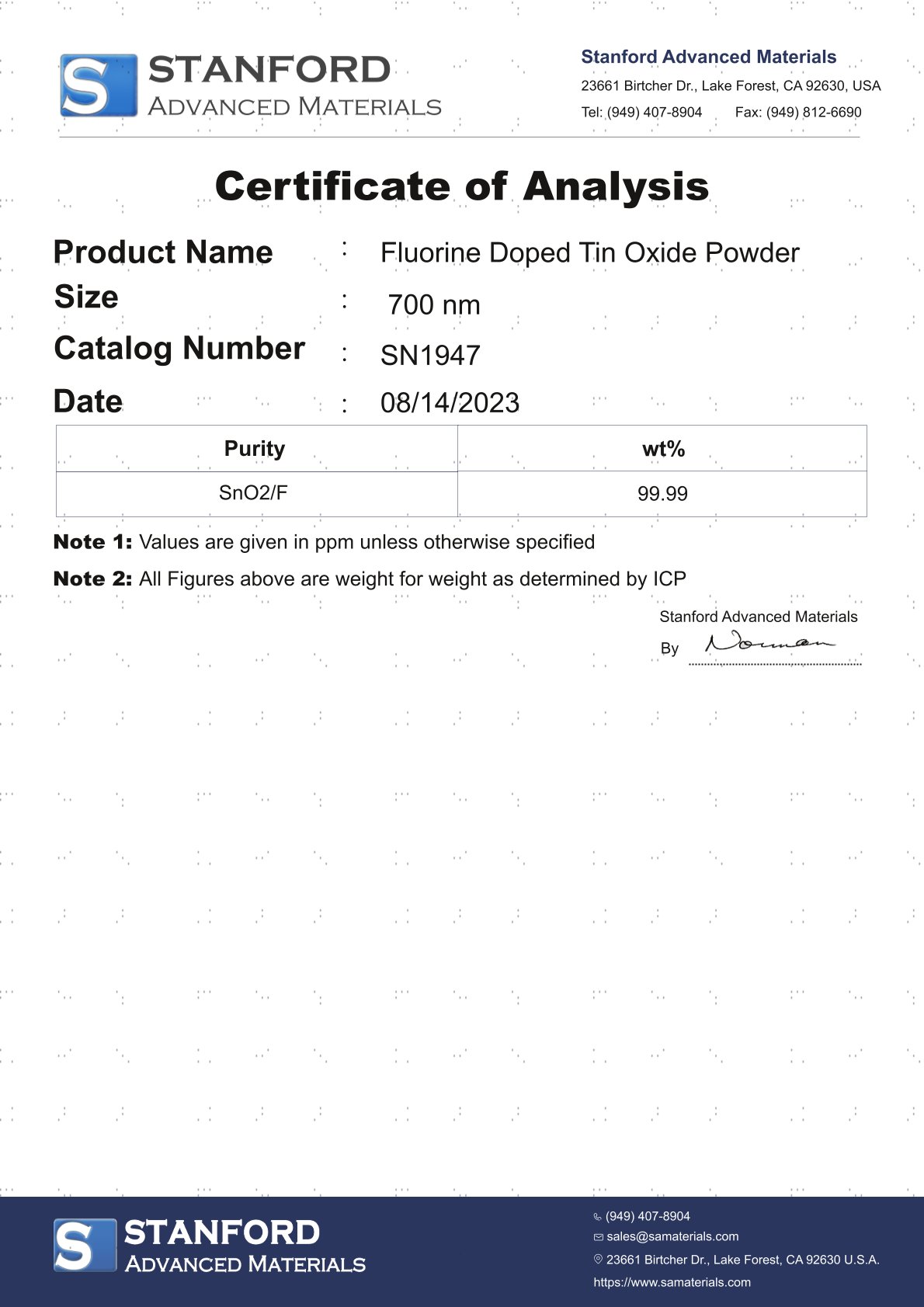

SN1947 Fluorine Doped Tin Oxide Powder

| Catalog No. | SN1947 |

| Appearance | Green powder |

| Purity | 99.99 % |

| Particle Size | -35 +50 mesh |

Stanford Advanced Materials (SAM) is a trusted supplier of functional composite with excellent quality and competitive price.

Other related product: ITO0491 Indium Tin Oxide (ITO) Sputtering Targets, SnS powder, Tin (IV) Sulfide (SnS2) Powder/Chunk/Lumps.

INQUIRY

Add to Inquiry List

Description

Specification

Technical Data Sheet

LATEST RECOMMENDED

NN0265 Nano Tin Powder (Sn) (CAS No.7440-31-5)

SN0266 Micro Tin Powder (Sn) (CAS No. 7440-31-5)

ST0424 Fluorine Doped Tin Oxide FTO Sputtering Target

ITO0491 Indium Tin Oxide (ITO) Sputtering Targets

VD0585 Tin (Sn) Evaporation Materials

VD0648 Tin Zinc (Sn/Zn) Evaporation Materials

AL2445 (Discontinued) AZO Coated Glass

SN2806 (Discontinued) Tin (IV) Iodide Powder (CAS 7790-47-8)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!