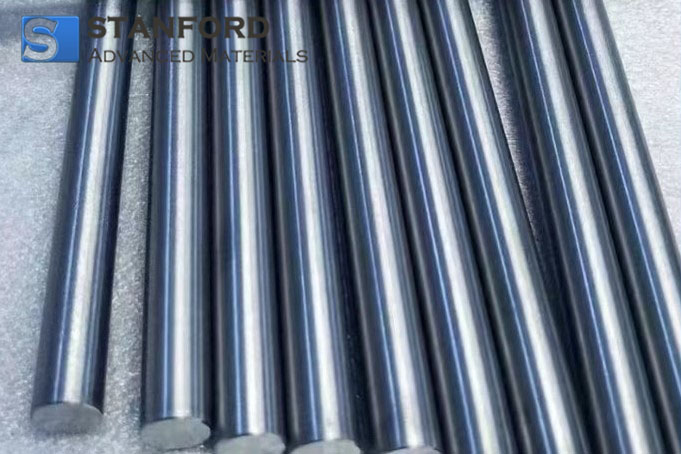

Tantalum Tungsten Wire Description

Tantalum tungsten is a high strength metal alloy. It has a high melting point, tension resistance and corrosion resistance. SAM’s tantalum alloys are made using power metallurgy techniques by mixing tantalum powder with alloy elements and filling them into molds, compressing them at temperatures of up to 2000 bars, and then sintering them. Tantalum tungsten alloys are stronger than pure tantalum and are useful for corrosion and heat applications at temperatures of up to 1600 °C, making them an excellent material for wire.

Tantalum Tungsten Wire Specification

|

Material

|

Ta2.5W

|

Ta10W

|

|

Grade

|

UNS Grade R05252

|

UNS GradeR5255

|

|

Standard

|

ASTM B365

|

|

Size

|

0.10~4mm (0.004"~0.5")

0.10mm~0.15mm, tolerance:±0.005

>0.15mm~0.30mm, tolerance: ±0.006

>0.30mm, tolerance: ±0.007

|

|

Purity

|

≥99.95%, 99.99%

|

Chemical Composition

| Element |

R05255

(Ta10W)

(%,Max) |

R05252

(Ta2.5W)

(%,Max) |

| C |

0.01 |

0.01 |

| O |

0.015 |

0.015 |

| N |

0.01 |

0.01 |

| H |

0.0015 |

0.0015 |

| Fe |

0.01 |

0.01 |

| Mo |

0.02 |

0.02 |

| Nb |

0.1 |

0.5 |

| Ni |

0.01 |

0.01 |

| Si |

0.005 |

0.005 |

| Ti |

0.01 |

0.01 |

| W |

9.0–11.0 |

2.0–3.5 |

Tantalum Tungsten Wire Application

1. Aerospace: Due to its extremely high melting point and excellent thermal stability, Tantalum Tungsten Wire is often used in the manufacture of high-temperature components in aerospace vehicles, such as rocket engine nozzles, combustion chambers, etc. These components operate under extremely high-temperature environments and require materials with excellent high-temperature resistance, which is exactly what is needed. These parts work in extremely high-temperature environments, requiring materials with excellent high-temperature resistance, and tantalum tungsten wires just to meet this demand.

2. In the field of nuclear industry: Tantalum Tungsten Wire has become a key material in nuclear reactors due to its strong radiation resistance and good thermal stability. It can be used to manufacture structural parts of reactors, heat exchangers and radiation shielding materials, etc. to ensure the safe and stable operation of nuclear facilities in a strong radiation environment.

3. In the field of electronics industry: Tantalum Tungsten Wire has good conductivity and high temperature resistance, which makes it an ideal material for electronic components. It can be used to manufacture electrodes, leads and connecting wires for high-temperature electronic devices, such as vacuum electron tubes and thermocouples for high-temperature furnaces.

4. Medical devices and surgical tools: Due to the good biocompatibility of Tantalum Tungsten Wire and its high hardness and wear resistance, it is often used in the manufacture of medical devices and surgical tools, such as surgical sutures and cutting tools. These tools need to withstand certain mechanical pressure and friction during the medical process, and tantalum tungsten wires can maintain stable performance and long service life.

5. High-temperature furnace and electric heating element: Tantalum Tungsten Wire is often used to manufacture heating elements and electric heating wires for high-temperature furnaces because of its high melting point and good electrical properties. It can work under high temperatures for a long time without melting or deformation, ensuring the stable operation and heating efficiency of the high-temperature furnace.

6. Special welding and joining technology: In some special welding and joining processes, it is necessary to use metal materials that can withstand high temperatures and good stability. Tantalum Tungsten Wires are indispensable for these processes due to their high-temperature stability and excellent electrical conductivity.

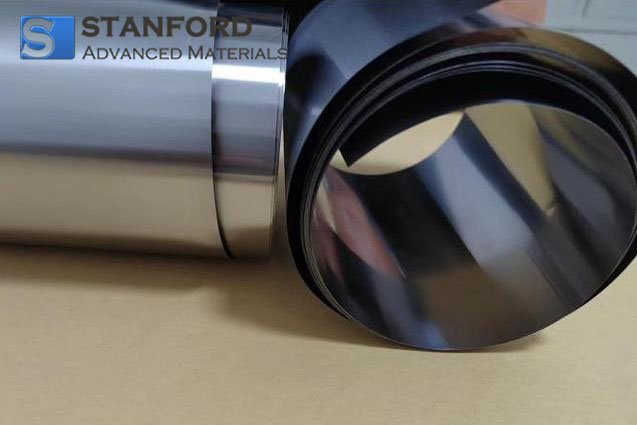

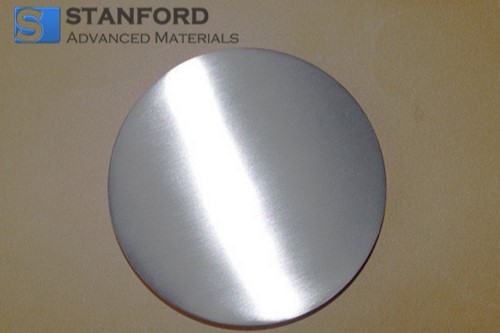

Tantalum Tungsten Wire Packaging

Our tantalum tungsten alloys are carefully handled to prevent damage during storage and transportation and to preserve the quality of our product in its original condition.

Tantalum Tungsten Wire (Ta-W Wire) FAQs

1. What are the benefits of using Tantalum Tungsten Wire (Ta-W Wire)?

Tantalum Tungsten Wire offers several key benefits, including superior resistance to corrosion, high strength, and excellent performance in high-temperature environments. It is ideal for industries where high-density, durable, and heat-resistant materials are needed, such as in aerospace, chemical reactors, and welding.

2. How is Tantalum Tungsten Wire (Ta-W Wire) manufactured?

Tantalum Tungsten Wire is produced through processes like extrusion, drawing, and sintering. After the initial production, the wire is often further processed to the required diameter, purity, and mechanical properties. This ensures that the wire meets the high standards needed for industrial and aerospace applications.

3. Is Tantalum Tungsten Wire resistant to corrosion?

Yes, Tantalum Tungsten Wire is highly resistant to corrosion, even in the most aggressive environments. Tantalum provides superior resistance to chemical attack, especially in acids and alkalis, while tungsten enhances the wire's structural integrity, making it suitable for chemically harsh applications.

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano

.jpg)