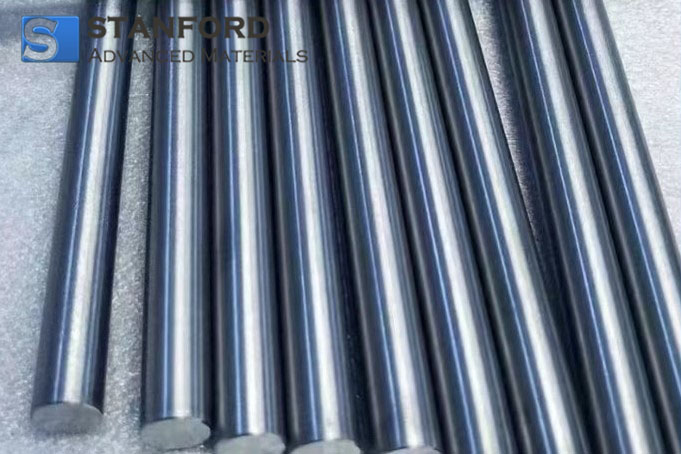

Tantalum Tungsten Rod & Tantalum Tungsten Bar Description

Tantalum Tungsten Alloy Rods and Bars are extremely strong and hard and are able to withstand extreme pressure and impact, making them ideal for components and structures that are subjected to high loads. Tantalum tungsten alloys maintain their good mechanical properties and chemical stability at high temperatures and do not soften or deform due to high temperatures, which gives them excellent performance in high temperature environments. Tantalum-tungsten alloys show excellent resistance to a wide range of chemicals and corrosive media, and are able to keep their performance stable for a long time in harsh corrosive environments. This alloy material has excellent performance in electrical and thermal conductivity, making it potentially valuable for applications in electronics, electric power and heat conduction.

Tantalum Tungsten Rod & Tantalum Tungsten Bar Specification

|

Product

|

Tantalum Tungsten Rod / Tantalum Tungsten Bar

|

|

Size

|

Diameter: 1 inch ~ 8 inch

Length:< 10 feet

|

|

Material

|

R05255 (TA10W), R05252 (TA2.5W)

|

|

Standard

|

ASTM B365; ASTM F560

|

|

Purity

|

≥99.95% or 99.99%

|

Tantalum Tungsten Rod & Tantalum Tungsten Bar Applications

• Used as a heating exchanger and heating element in chemical processing due to its high heat resistance.

• Used to manufacture of super alloys and electron-beam melting

• Used as heat- and corrosion-resistant alloy additives.

Chemical Composition

| Element |

R05255

(Ta10W)

(%,Max) |

R05252

(Ta2.5W)

(%,Max) |

| C |

0.01 |

0.01 |

| O |

0.015 |

0.015 |

| N |

0.01 |

0.01 |

| H |

0.0015 |

0.0015 |

| Fe |

0.01 |

0.01 |

| Mo |

0.02 |

0.02 |

| Nb |

0.1 |

0.5 |

| Ni |

0.01 |

0.01 |

| Si |

0.005 |

0.005 |

| Ti |

0.01 |

0.01 |

| W |

9.0–11.0 |

2.0–3.5 |

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace or vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, Ta-W alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, Ta-W alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, Ta-Nb alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Tantalum Tungsten Rod & Tantalum Tungsten Bar Applications

1. Aerospace: In the aerospace industry, Tantalum Tungsten Alloy Rods and Bars are widely used in the manufacture of engine parts, rocket nozzles, thermal protection systems and other key components due to their high strength, high temperature and corrosion resistance. These parts need to work under extremely high temperature and high-speed airflow, and the excellent performance of tantalum tungsten alloy can ensure their reliability and durability.

2. Nuclear industry: Tantalum-tungsten alloy plays an important role in the nuclear industry. Due to its high resistance to radiation, it is often used in the manufacture of fuel cladding, control rods and other key components of nuclear reactors. These components need to operate stably for long periods under high radiation and high temperatures, and Tantalum-Tungsten alloys provide the necessary protection and stability.

3. Electronics industry: Tantalum-tungsten alloy's excellent conductivity properties make it an ideal material for the electronics industry. It can be used to manufacture electronic components such as capacitors, resistors and electrodes, as well as connecting wires and contacts for high-temperature electronic equipment.

4. Chemical industry: Tantalum-tungsten alloy is also widely used in the chemical industry. Due to its excellent corrosion resistance, it can be used to manufacture corrosion-resistant reactors, pipelines, valves and other chemical equipment, ensuring stable operation in harsh chemical environments.

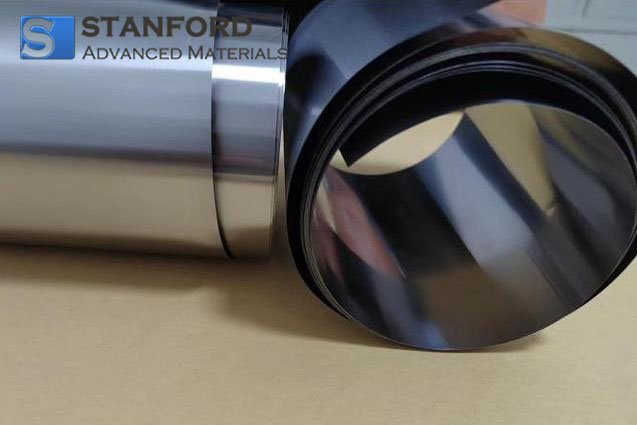

Tantalum Tungsten Rod & Tantalum Tungsten Bar Packaging

Our tantalum tungsten alloys are carefully handled to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.

Tantalum Tungsten Rod, Tantalum Tungsten Bar FAQs

1 What are the benefits of using Tantalum Tungsten Rods and Bars?

Tantalum Tungsten Rods and Bars provide superior corrosion resistance, high density, and exceptional heat resistance, making them suitable for high-temperature environments. Their mechanical strength ensures durability under stress, and they are well-suited for use in chemical reactors, aerospace applications, and heat exchangers.

2. How are Tantalum Tungsten Rods and Bars manufactured?

Tantalum Tungsten Rods and Bars are typically manufactured through precision extrusion, sintering, or forging processes, followed by further machining to the required dimensions. The materials are carefully processed to ensure high purity and optimal mechanical properties for industrial use.

3. Are Tantalum Tungsten Rods and Bars resistant to corrosion?

Yes, Tantalum Tungsten Rods and Bars have excellent corrosion resistance, particularly in harsh environments such as acidic or alkali-rich settings. This makes them ideal for use in chemical processing, reactors, and applications where the material may be exposed to reactive chemicals.

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano

.jpg)