- Products

- Categories

- Blog

- Podcast

- Application

- Document

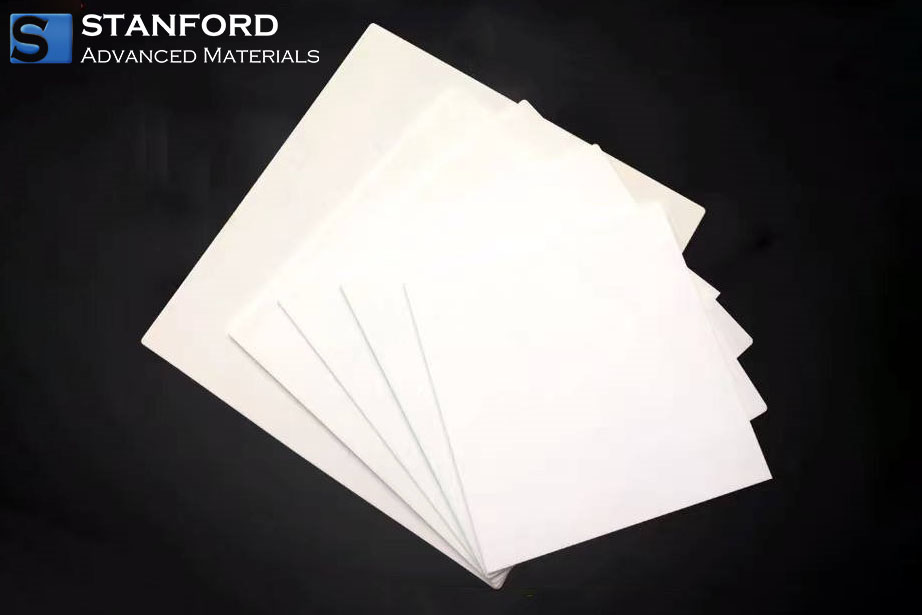

PBN1343 Pyrolytic Boron Nitride Sheet (PBN Sheet)

| Catalog No. | PBN1343 |

| Size | Thikness: 0.5mm~4mm |

| Material | Pyrolytic Boron Nitride (PBN) |

| Purity | 99.99% |

| Shape | sheet |

Pyrolytic Boron Nitride Sheet provided by Stanford Advanced Materials is a high-performance material known for its excellent thermal conductivity, electrical insulation, and chemical resistance, making it ideal for use in high-temperature and high-tech applications.

Related products: Pyrolytic Boron Nitride Strip

INQUIRY

Add to Inquiry List

Description

Specification

Technical Data Sheet

Video

LATEST RECOMMENDED

HBN0921 Hot Pressed Boron Nitride Ring (BN Ring)

PBN0922 Pyrolytic Boron Nitride Crucible, PBN Crucibles

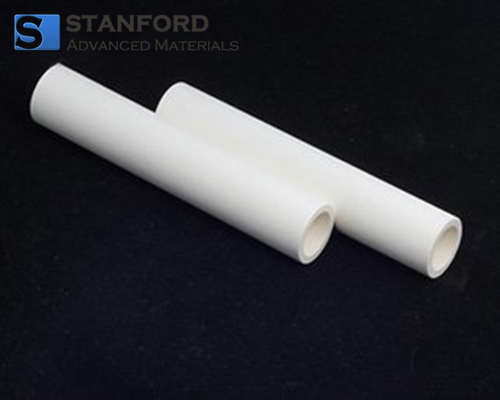

PBN0923 Pyrolytic Boron Nitride (PBN) Tubes

BN0948 Pyrolytic Boron Nitride (PBN) Disc

PBN0953 PBN/PG Composite Heating Elements

PBN0955 PBN Machined Products

PBN0956 PBN Coated Graphite Products

BN0997 Boron Nitride Blank (BN Blank)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!