Zirconium Custom Fabrication Description

Zirconium Custom Fabrication involves the tailored manufacturing of zirconium-based components to meet specific industrial requirements. Known for its exceptional corrosion resistance, high melting point, and biocompatibility, zirconium is utilized in diverse applications ranging from chemical processing to medical implants. Through custom fabrication, zirconium parts can be precision-engineered to exact specifications, ensuring optimal performance and durability in harsh environments. Whether for critical components in nuclear reactors or corrosion-resistant equipment in chemical plants, Zirconium Custom Fabrication offers tailored solutions for industries demanding reliability and longevity in their operations.

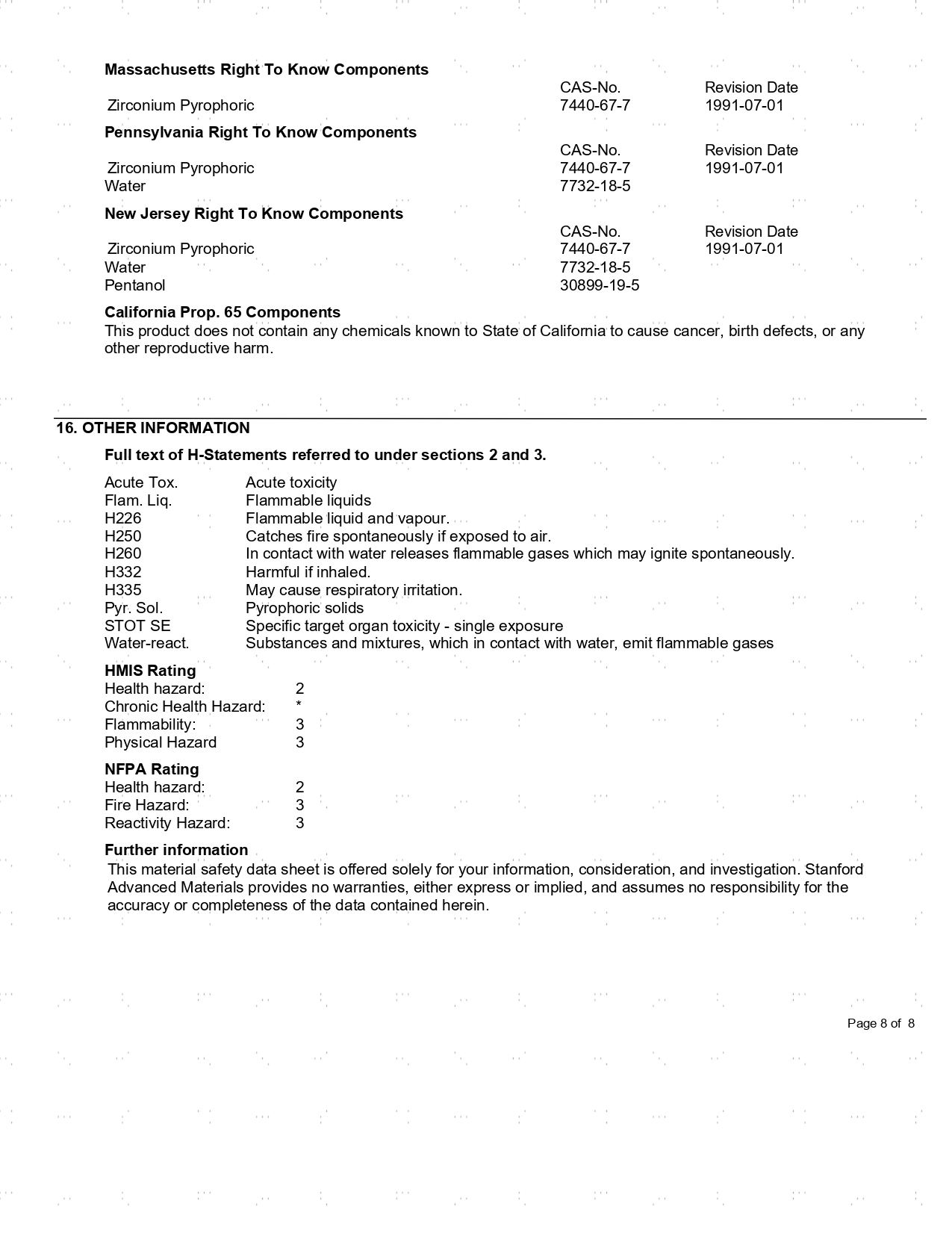

Zirconium Custom Fabrication Specification

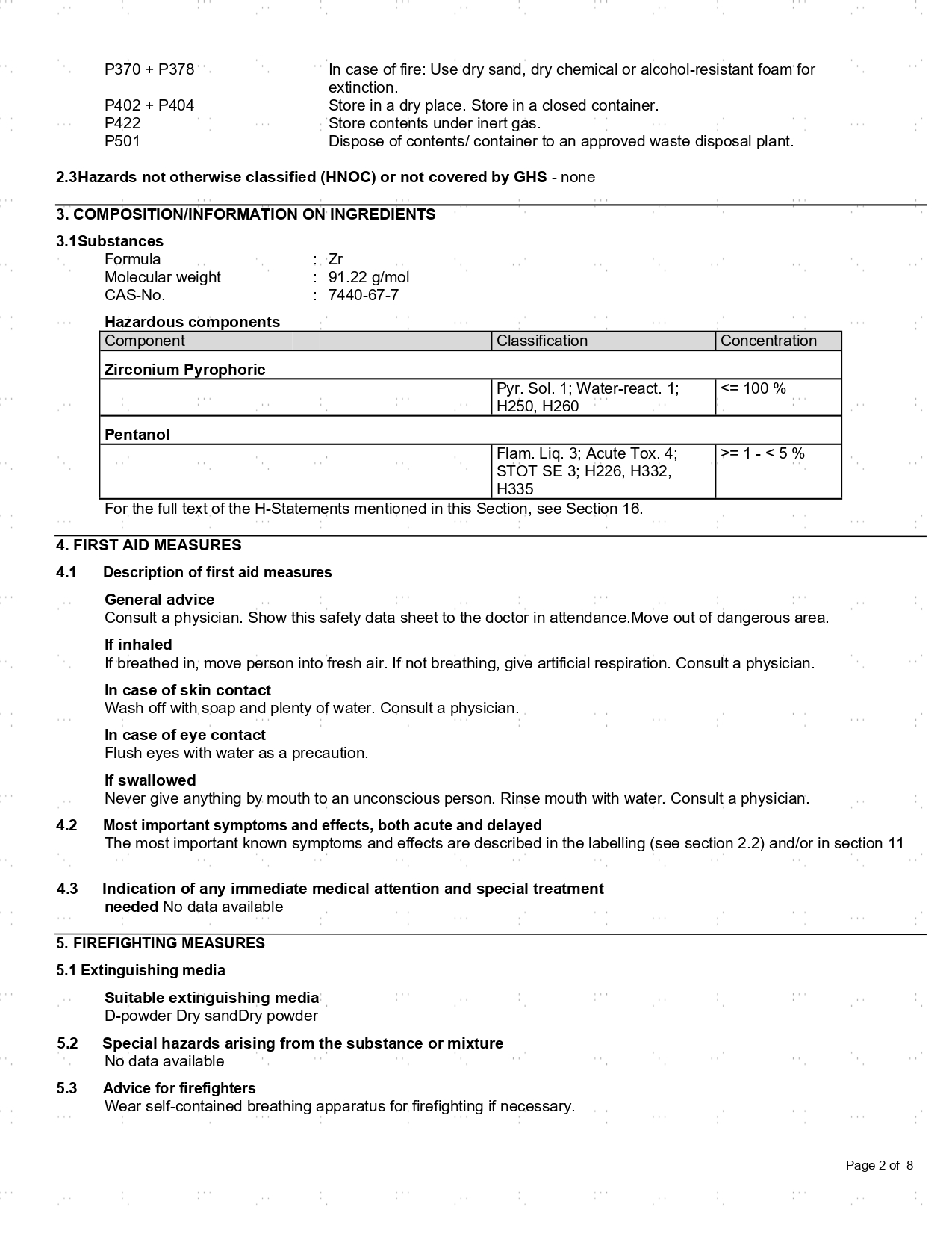

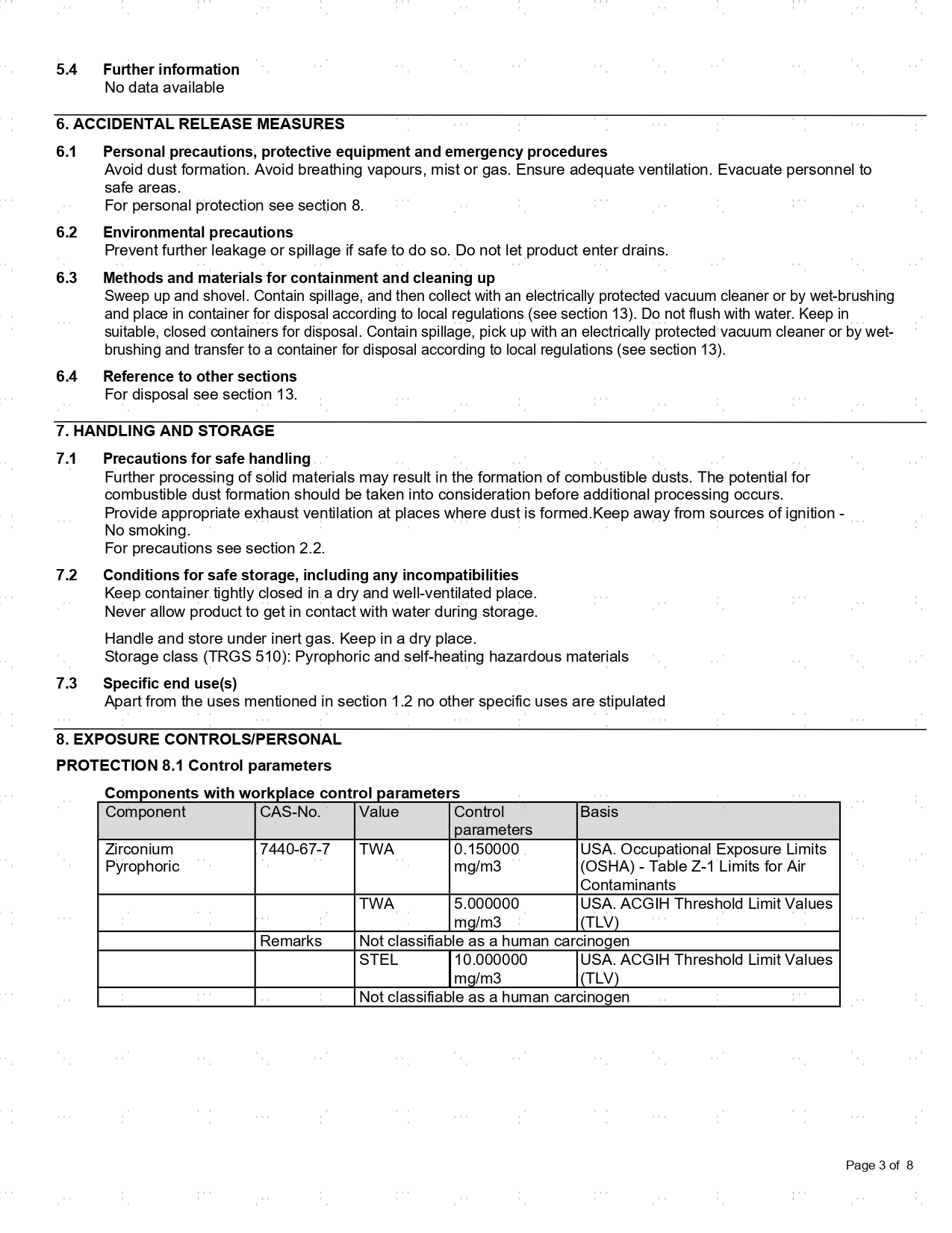

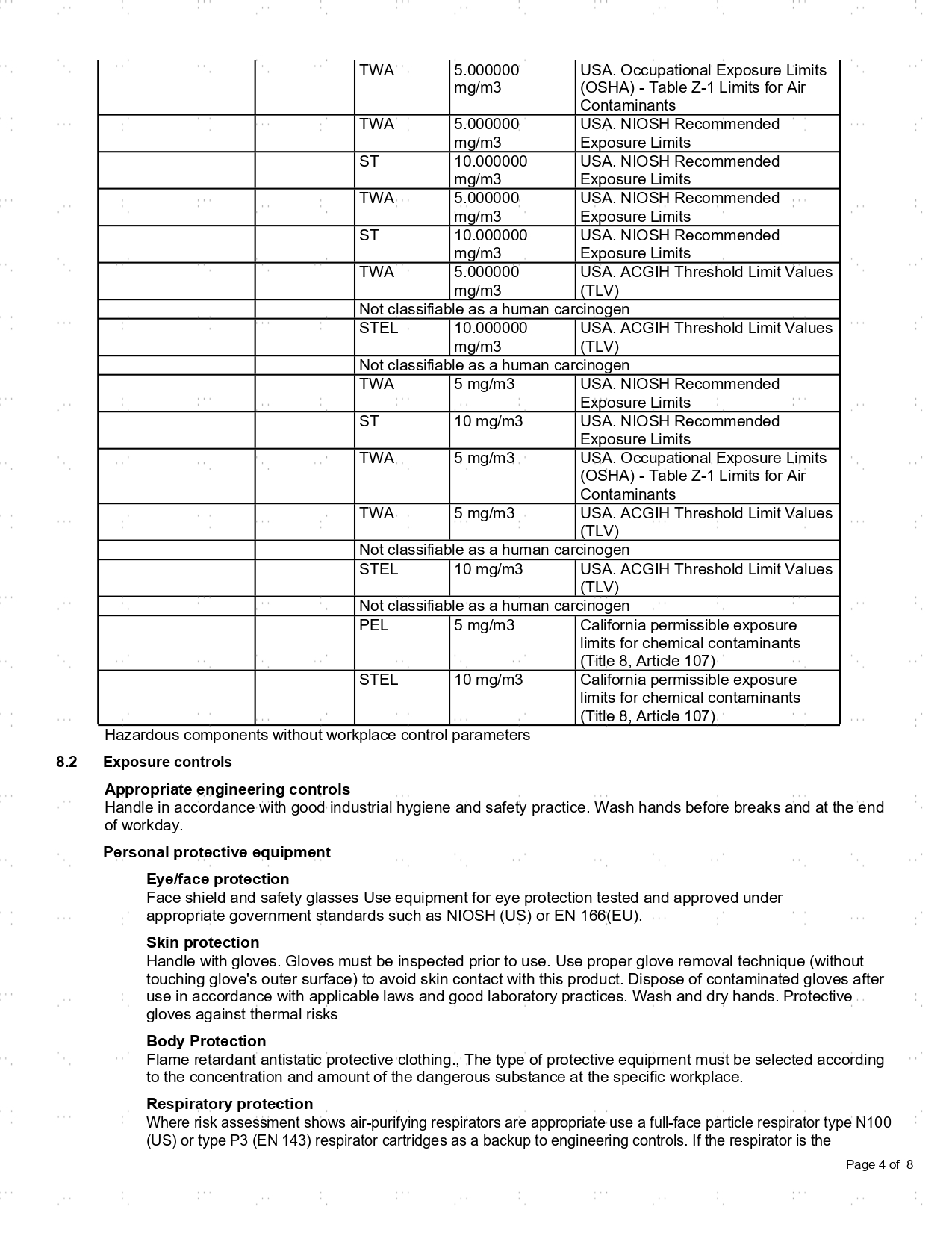

Typical Zirconium Materials

| |

Zr 702 |

Zr 704 |

Zr 705 |

High Purity Zirconium |

| Sn |

/ |

1~2% |

1~2% |

<50ppm |

| Fe |

<0.05% |

0.1~0.2% |

<0.05% |

<100ppm |

| Cr |

<0.05% |

0.1~0.2% |

<0.01% |

<10ppm |

| Ni |

/ |

/ |

/ |

<10ppm |

| Hf |

1~2.5% |

1~2.5% |

1~2.5% |

1~2.5% |

| Nb |

/ |

/ |

2~3% |

<10ppm |

| Zn+Hf |

~99.5% |

~97.5% |

~95.5% |

>99.95% |

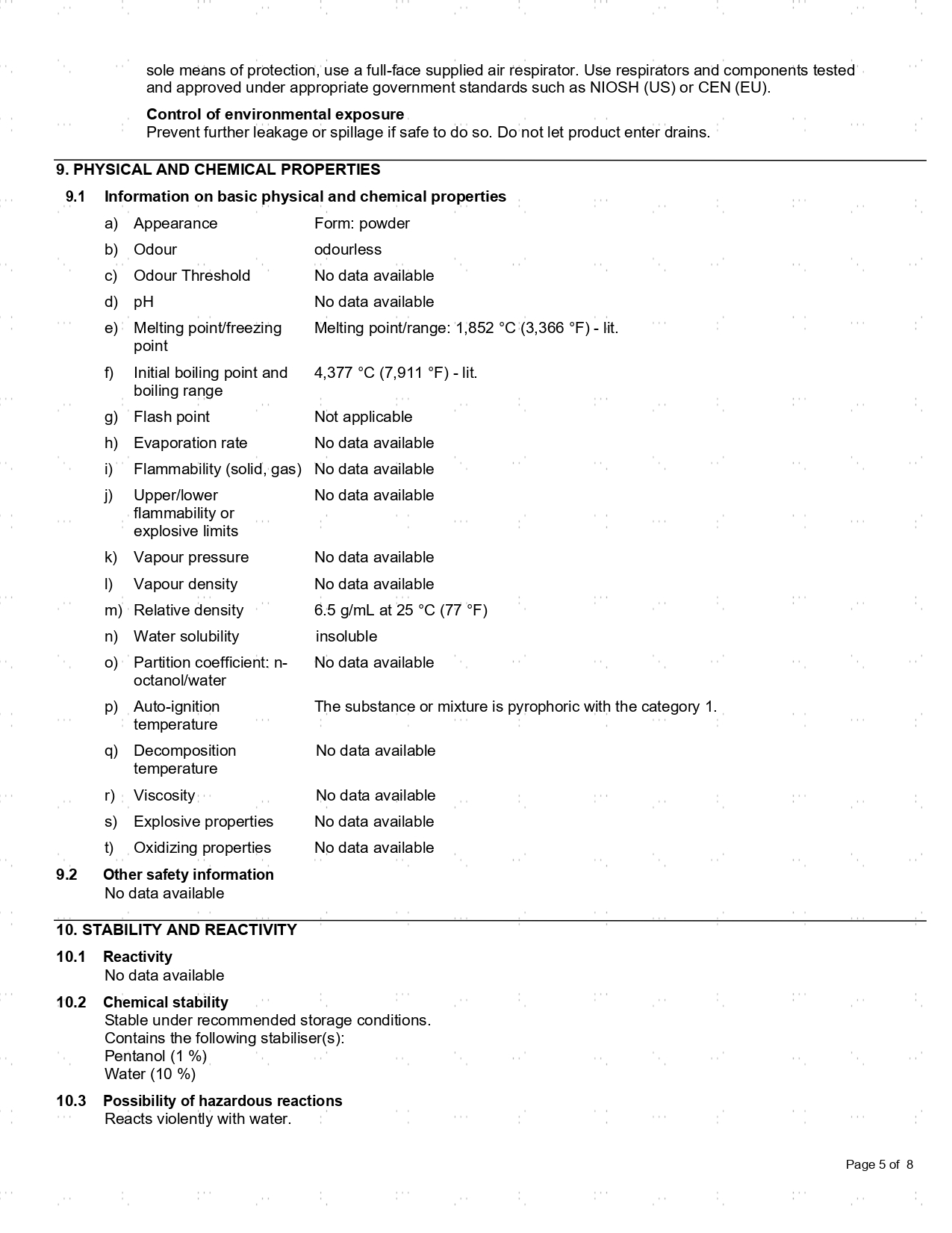

Physical Properties

| Material |

State |

Rm(≥)/MPa |

Rp0.2(Pa) |

A50mm(≥)/% |

| Zirconium 702 |

annealed |

379 |

207 |

16 |

| (UNS R60702) |

| Zirconium 704 |

annealed |

413 |

241 |

14 |

| (UNS R60704) |

| Zirconium 705 |

annealed |

552 |

379 |

16 |

| (UNS R60705) |

Zirconium Custom Fabrication Applications

1. Chemical industry: Used in the manufacture of corrosion-resistant equipment, such as chemical reactors, pipelines and vessels, to handle corrosive chemicals and solutions.

As a material for the catalyst support body, it is used in various chemical reactions and catalytic processes.

2. Nuclear energy industry: Used in the manufacture of nuclear reactor components such as fuel rod casings, reactor pressure vessels and coolant circulation systems, favoured for their good corrosion resistance and mechanical properties.

Used for equipment in nuclear fuel processing and reprocessing, as well as auxiliary systems and accessories.

3. Medical devices: Used in the manufacture of medical implants and surgical instruments such as artificial joints, dental equipment and bone implants, favoured for their biocompatibility and corrosion resistance.

4. Aerospace industry: For the manufacture of aero-engine parts, spacecraft structures and propulsion system components to meet the challenges of extreme temperature and corrosive conditions.

5. Chemical Processes: Used in the manufacture of equipment subject to high temperatures, pressures and corrosive media, such as reactors and heat exchangers in ammonia plants, petroleum refineries and chlor-alkali plants.

6. Oil and gas industry: Used in the manufacture of equipment for oil and gas extraction, both offshore and onshore, such as drilling rigs, pipelines and anti-corrosion coatings to cope with the corrosive effects of seawater and oil and gas media.

Zirconium Custom Fabrication Packing

Our Zirconium Custom Fabrication products are carefully handled to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.

Related articles:

What Is Zirconium Used For? Nuclear And More

Where Zirconium is Used

Separation of Zirconium and Hafnium

The Application of Zirconium Products

.jpg)

.jpg)