- Products

- Categories

- Blog

- Podcast

- Application

- Document

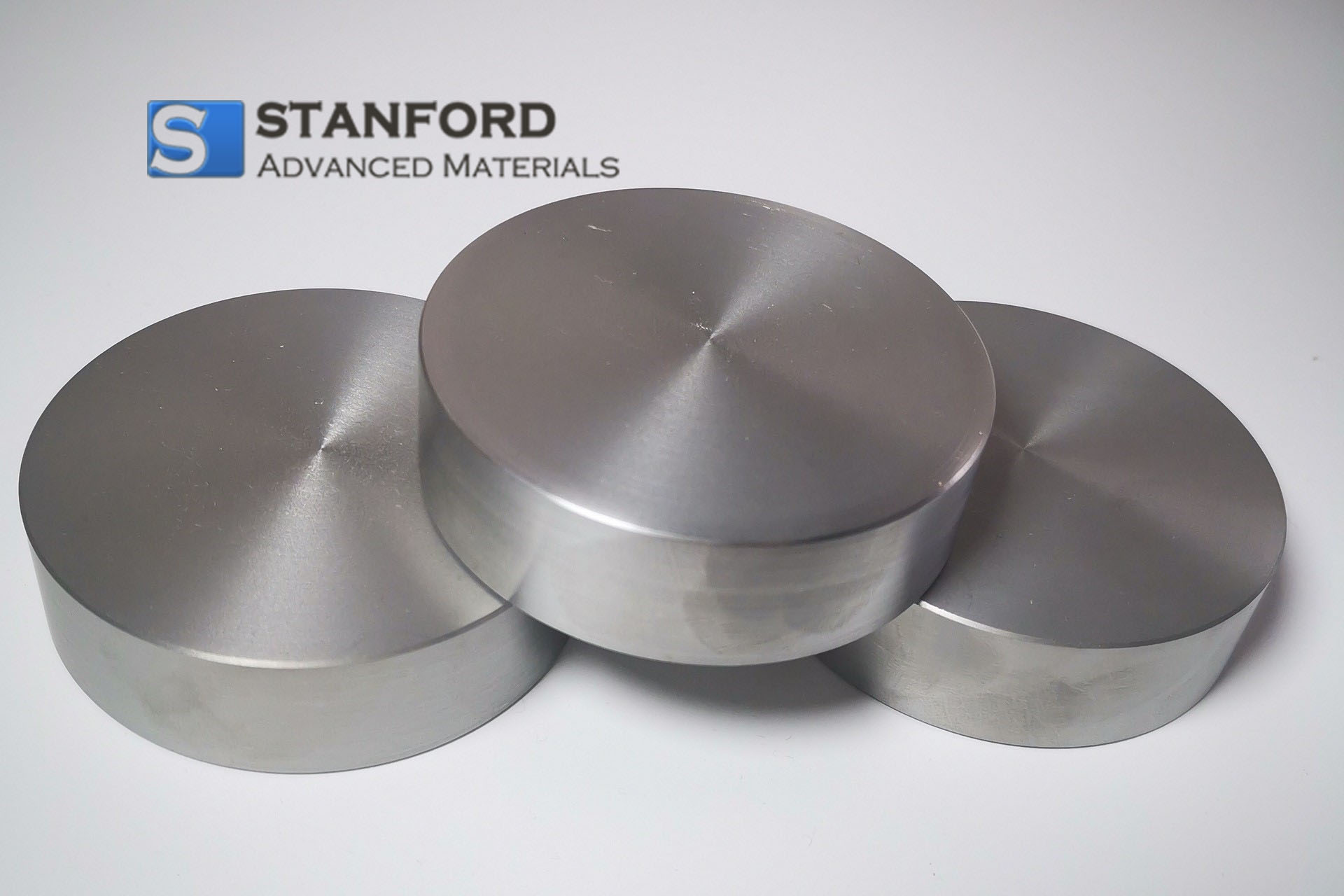

ST0982 Zirconium Sputtering Target (Zr Sputtering Target)

| Catalog No. | ST0982 |

| Material | Zr crystal bar |

| Purity | 99.95% |

| CAS Number | 7440-67-7 |

| Color | Silver |

| Shape | Diameter: 20~40mm |

| MSDS/SDS |

Zirconium sputtering targets are high-purity materials used in thin-film deposition for applications like optics, electronics, and corrosion-resistant coatings, valued for their strong durability and chemical stability.

Related Products: Zirconium Ribbon, Zirconium Ring, Zirconium Rod, Zirconium Sheet

INQUIRY

Add to Inquiry List

Description

Specification

Technical Data Sheet

Video

LATEST RECOMMENDED

ZR0273 Micro Zirconium Powder (Zr)

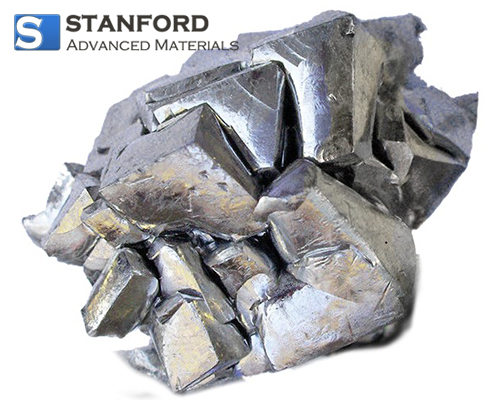

ZR0878 Zirconium Crystal Bar (Zr Crystal Bar)

ZR0899 Zirconium Rod (Zr Rod)

ZR0900 Zirconium Plate (Zr Plate)

ZR0901 Zirconium Tube, Zirconium Pipe

.jpg)

ZR0902 Zirconium Foil (Zr Foil)

.jpg)

ZR0929 Zirconium Wire (Zr Wire)

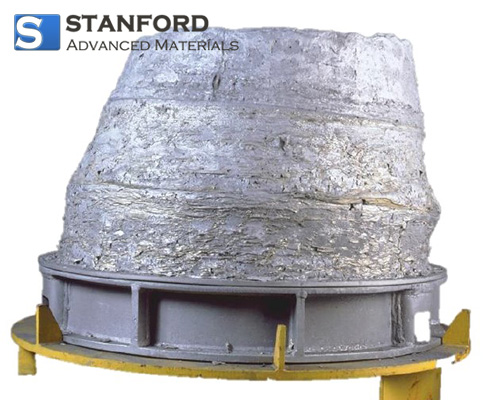

ZR3281 (Discontinued) Zirconium Sponge - Nuclear Grade

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!