- Products

- Categories

- Blog

- Podcast

- Application

- Document

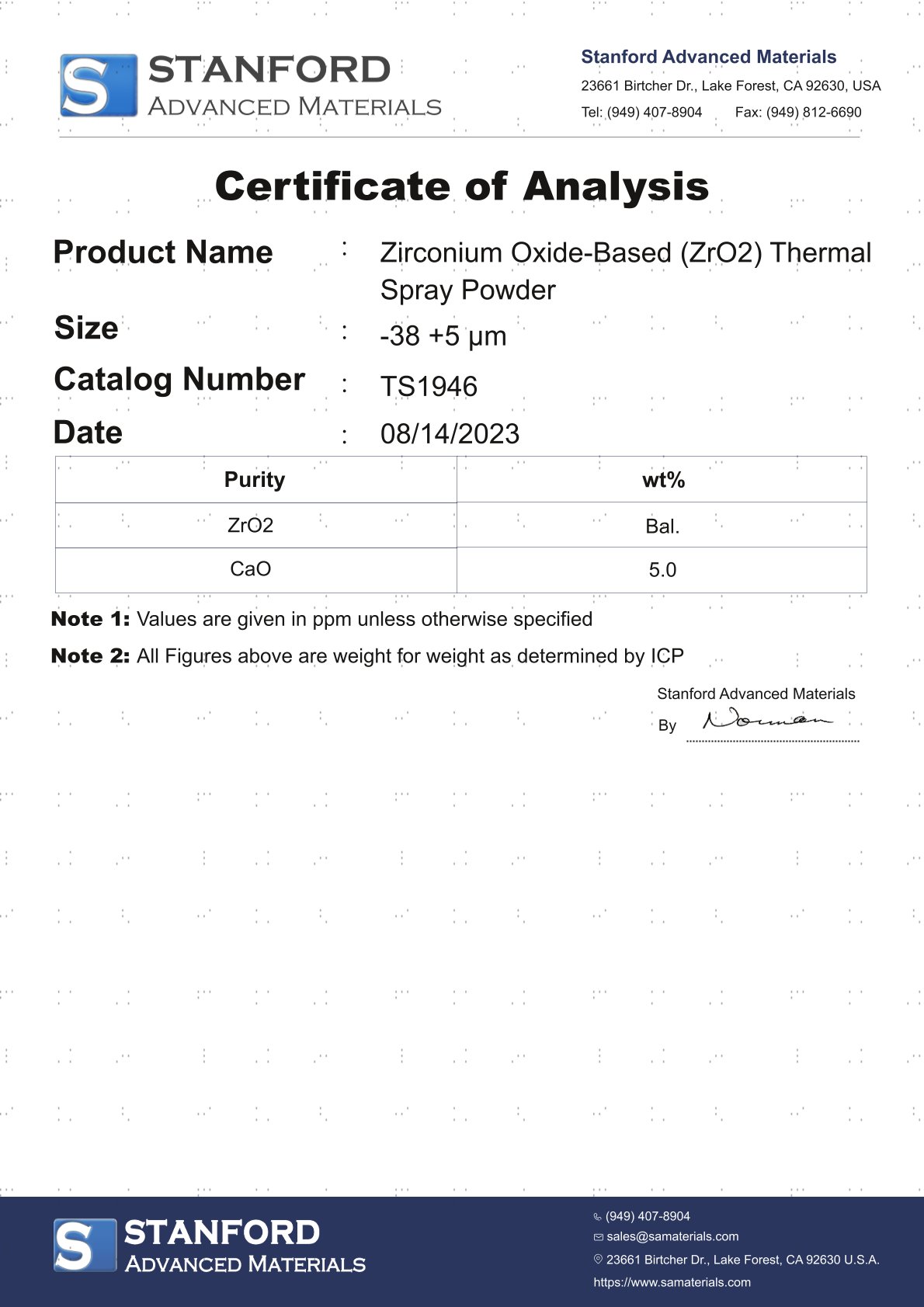

TS1946 Zirconium Oxide-Based (ZrO2) Thermal Spray Powder

| Catalog No. | TS1946 |

| Material | Zr2O3-CaO, ZrO2-CaCO3, ZrO2-Y2O3, etc. |

| Appearance | White powder |

Upgrade your thermal spray applications with our high-quality Zirconium Oxide-Based (ZrO2) Thermal Spray Powder. We offer thermal sprays with excellent thermal shock and heat resistance.

Other related products: Zirconium Carbide (ZrC) Powder, Zirconium Silicate Powder, Aluminum Oxide (Alumina, Al2O3) for Thermal Spraying

INQUIRY

Add to Inquiry List

Description

Specification

Technical Data Sheet

LATEST RECOMMENDED

CA0063 Niobium Carbide Powder (CAS No. 12069-94-2)

BR0068 Niobium Boride Powder, NbB Powder (CAS No. 12045-19-1)

NR0069 Niobium Nitride Powder (CAS No. 24621-21-4)

NB0070 Niobium Silicide Powder, NbSi2 Powder (CAS No. 12034-80-9)

WM0146 Tungsten Powder (W Powder)

TE1265 Lead Telluride (PbTe) Powder (CAS No.1314-91-6)

TS1369 (Discontinued) Aluminum Powder for Thermal Spraying

NN1616 (Discontinued) Nano Vanadium Nitride Powder VN (CAS No. 24646-85-3)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!