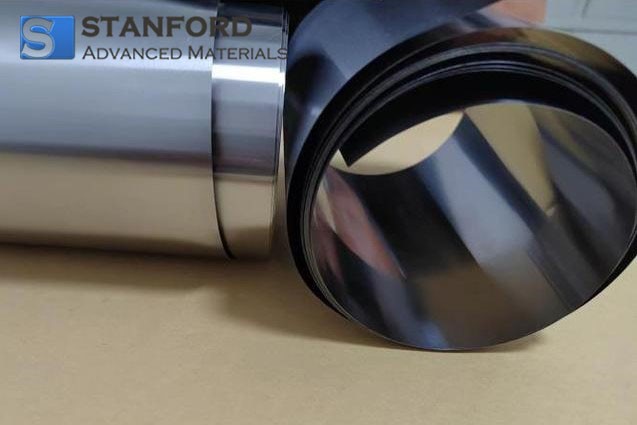

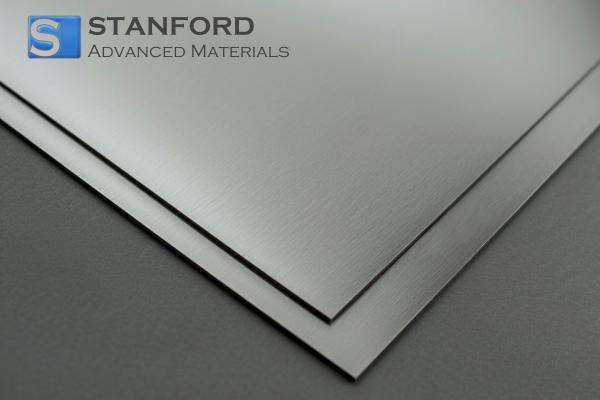

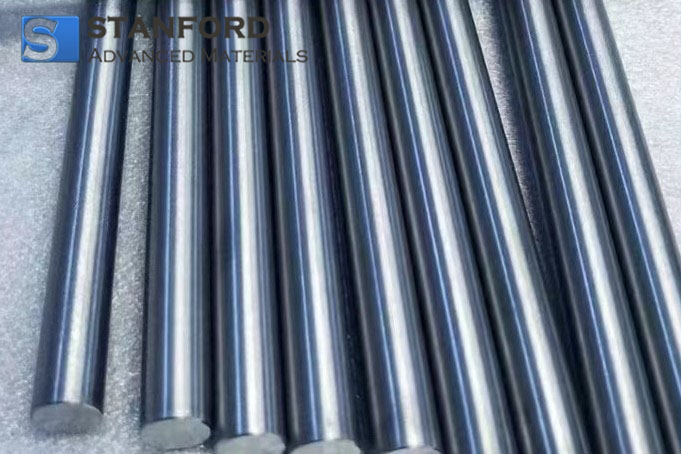

Tantalum Niobium Tube & Tantalum Niobium Pipe Descripiton

Tantalum Niobium Tubes and Pipes are renowned for their exceptional properties and diverse applications. These cylindrical forms exhibit outstanding corrosion resistance, making them essential in demanding environments such as chemical processing and aerospace industries. With high melting points and excellent thermal conductivity, they excel in extreme temperature conditions. Their precise dimensions and uniformity make them ideal for conveying fluids and gases in industrial processes and hydraulic systems. Tantalum Niobium Tubes and Pipes also demonstrate excellent weldability, allowing for seamless connections in complex systems. They play a crucial role in various technological advancements, ensuring durability and reliability in critical applications.

Tantalum Niobium Tube & Tantalum Niobium Pipe Specification

|

Product

|

Tantalum Niobium Alloy Tube

|

|

Size

|

Outer Diameter: 1.0~150mm

Wall Thickness: 0.2~5.0mm

Length: 200~6000mm

|

|

Material

|

R05240 (Ta-40Nb)

|

|

Standard

|

ASTM B521-98

|

|

Purity

|

99.95% or 99.99%

|

Chemical Composition

|

Element

|

R05240 (Ta-40Nb) (%,Max)

|

|

C

|

0.01

|

|

O

|

0.02

|

|

N

|

0.01

|

|

H

|

0.0015

|

|

Fe

|

0.01

|

|

Mo

|

0.02

|

|

Nb

|

35.0–42.0

|

|

Ni

|

0.01

|

|

Si

|

0.005

|

|

Ti

|

0.01

|

|

W

|

0.05

|

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace or vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, Ta-W alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, Ta-W alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, Ta-Nb alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Tantalum Niobium Tube & Tantalum Niobium Pipe Application

1. Chemical Processing: Utilized in the construction of reactors, heat exchangers, and piping systems for handling corrosive chemicals due to their exceptional corrosion resistance.

2. Aerospace: Employed in aircraft and spacecraft components like fuel lines, hydraulic systems, and heat exchangers due to their high strength-to-weight ratio and resistance to high temperatures.

3. Oil and Gas: Used in offshore drilling platforms, pipelines, and refining equipment due to their corrosion resistance and durability in harsh environments.

4. Medical Devices: Applied in medical gas delivery systems, such as oxygen delivery tubes and vacuum lines, due to their biocompatibility and resistance to bodily fluids.

5. Semiconductor Manufacturing: Utilized in vacuum systems and gas distribution lines for semiconductor fabrication processes due to their purity and stability in high vacuum environments.

6. Water Treatment: Used in desalination plants, wastewater treatment facilities, and water distribution systems due to their resistance to corrosion and chemical degradation.

7. Energy Generation: Employed in nuclear power plants for coolant systems, steam generators, and heat exchangers due to their resistance to radiation and high-temperature environments.

Tantalum Niobium Tube & Tantalum Niobium Pipe Packaging

Our Tantalum Niobium Tube & Tantalum Niobium Pipe products are carefully handled to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.