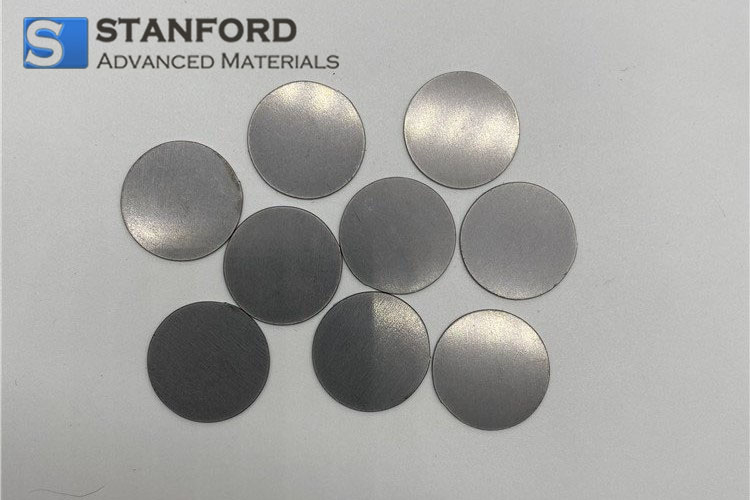

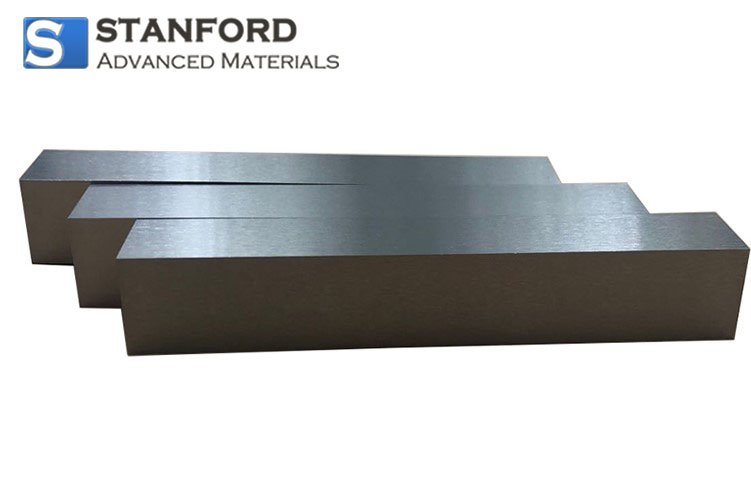

Tantalum Sputtering Target Description

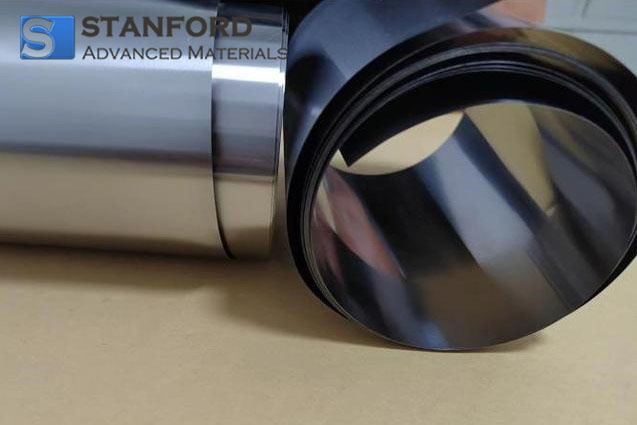

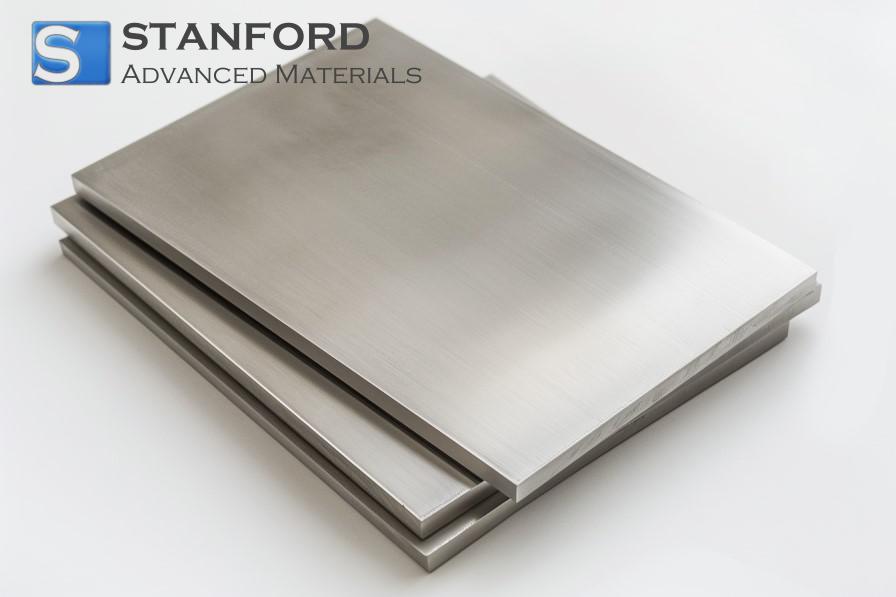

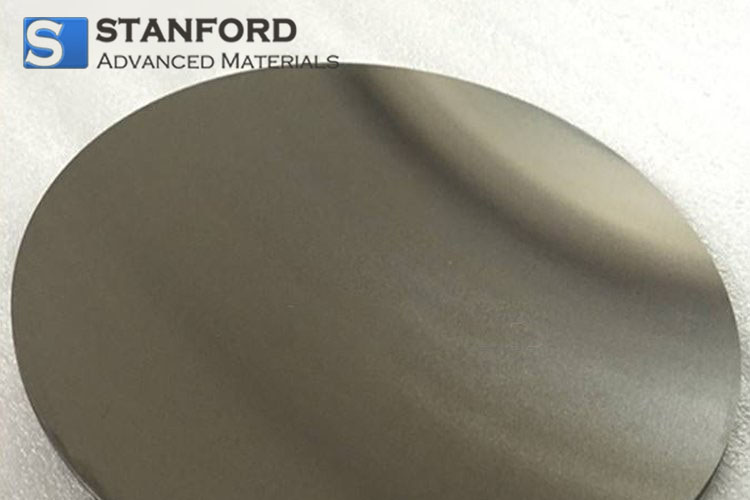

Stanford Advanced Materials (SAM) is renowned for providing high-quality Tantalum Sputtering Targets. These meticulously crafted targets are made from exceptionally pure tantalum, ensuring a consistent and reliable composition. The material's remarkable density enhances sputtering efficiency and results in improved film adhesion. Tantalum's exceptional thermal stability allows the targets to withstand extreme heating during sputtering, making them suitable for a range of high-temperature processes. Moreover, the material's exceptional corrosion resistance ensures the targets maintain their integrity, even under the most challenging sputtering conditions—the low levels of impurities and gas content in the tantalum result in superior film quality and uniformity. Additionally, the material's ease of machining allows for precise shaping according to specific application needs. Thanks to these exceptional properties, Tantalum Sputtering Targets have become the material of choice for depositing tantalum films in a range of industries, including electronics, optics, thin-film solar energy, and magnetic storage. Their adaptability and reliability make them a vital component in numerous sputtering deposition processes.

Tantalum Sputtering Target Specifications

|

Part No.

|

Material

|

Size

|

Purity

|

|

TA0201

|

Tantalum

|

1.00" Dia. x 0.125" Thick

|

99.95%

|

|

TA0202

|

Tantalum

|

1.00" Dia. x 0.250" Thick

|

99.95%

|

|

TA0203

|

Tantalum

|

2.00" Dia. x 0.125" Thick

|

99.95%

|

|

TA0204

|

Tantalum

|

2.00" Dia. x 0.250" Thick

|

99.95%

|

|

TA0205

|

Tantalum

|

3.00" Dia. x 0.250" Thick

|

99.95%

|

|

TA0206

|

Tantalum

|

3.00" Dia. x 0.250" Thick

|

99.95%

|

|

TA0207

|

Tantalum

|

4.00" Dia. x 0.250" Thick

|

99.95%

|

|

TA0208

|

Tantalum

|

4.00" Dia. x 0.250" Thick

|

99.95%

|

|

TA0209

|

Tantalum

|

5.00" Dia. x 0.250" Thick

|

99.95%

|

|

TA0210

|

Tantalum

|

5.00" Dia. x 0.250" Thick

|

99.95%

|

Need a tailor-made solution? Contact us.

We also provide high-quality Tantalum Disc.

Other information for your reference

Chemical Composition:

|

Element

|

R05200 (%,Max)

|

R05400 (%,Max)

|

|

C

|

0.01

|

0.01

|

|

O

|

0.015

|

0.03

|

|

N

|

0.01

|

0.01

|

|

H

|

0.0015

|

0.0015

|

|

Fe

|

0.01

|

0.01

|

|

Mo

|

0.02

|

0.02

|

|

Nb

|

0.1

|

0.1

|

|

Ni

|

0.01

|

0.01

|

|

Si

|

0.005

|

0.005

|

|

Ti

|

0.01

|

0.01

|

|

W

|

0.05

|

0.05

|

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace or vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Tantalum Sputtering Target Applications

1. Electronics: Tantalum Sputtering Targets are widely used in the electronics industry for the deposition of tantalum films in integrated circuits, capacitors, and other microelectronic components. The high purity and corrosion resistance of tantalum makes it an ideal material for these applications.

2. Optics: Tantalum Sputtering Targets are also used in the optical industry for the deposition of tantalum films on optical components, such as lenses and mirrors. The high transparency and hardness of tantalum make it suitable for this application.

3. Thin-film solar energy: Tantalum Sputtering Targets are employed in the production of thin-film solar cells. The deposition of tantalum films on solar cells enhances their efficiency and reliability.

4. Magnetic storage: In the magnetic storage industry, Tantalum Sputtering Targets are used to deposit tantalum films on magnetic disks and tapes, improving their durability and performance.

5. Decorative coatings: Due to the attractive appearance of tantalum, Tantalum Sputtering Targets are also used in the production of decorative coatings for various consumer products, such as jewelry and watches.

Tantalum Sputtering Target Packaging

Our tantalum sputtering targets are carefully handled during storage and transportation to preserve the quality of our products in their original condition.

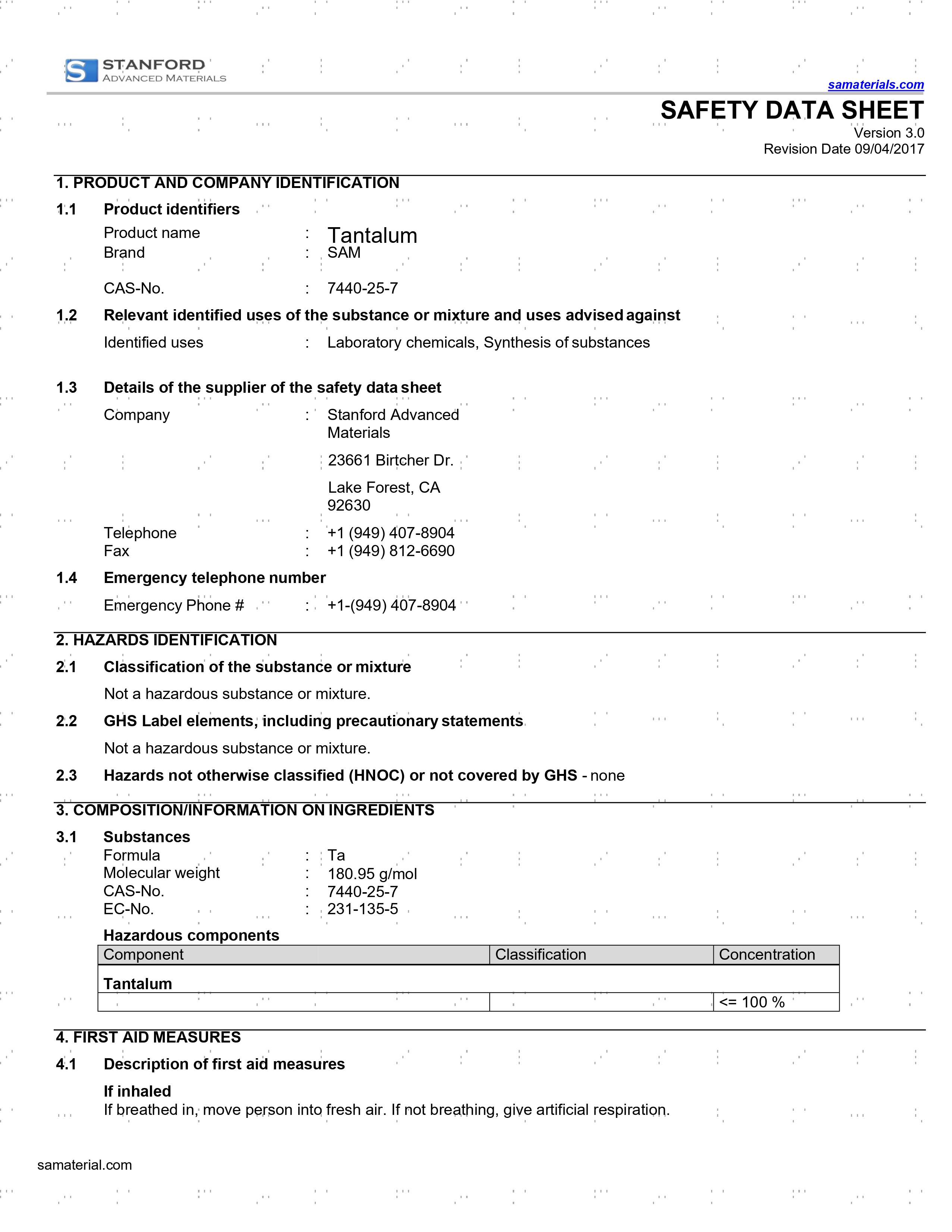

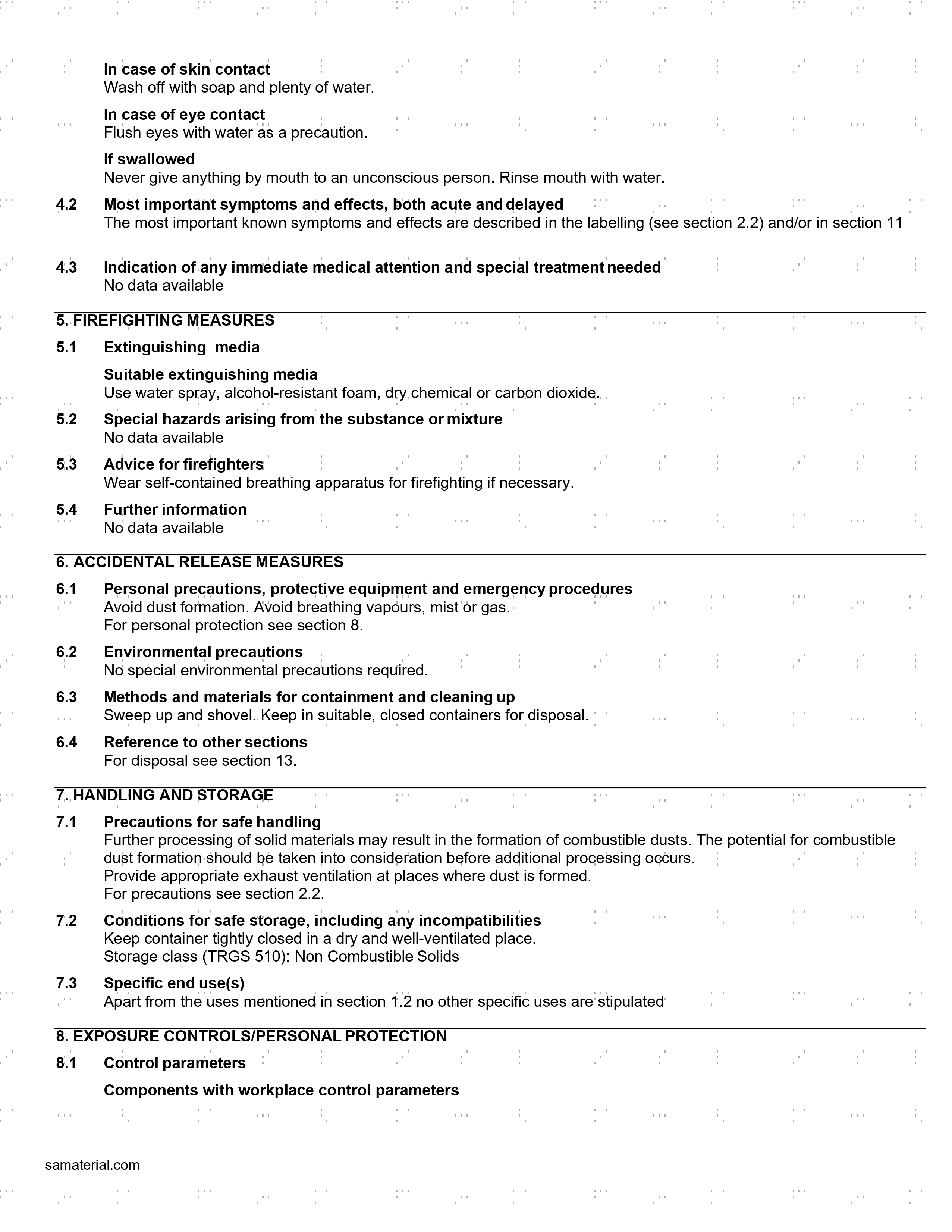

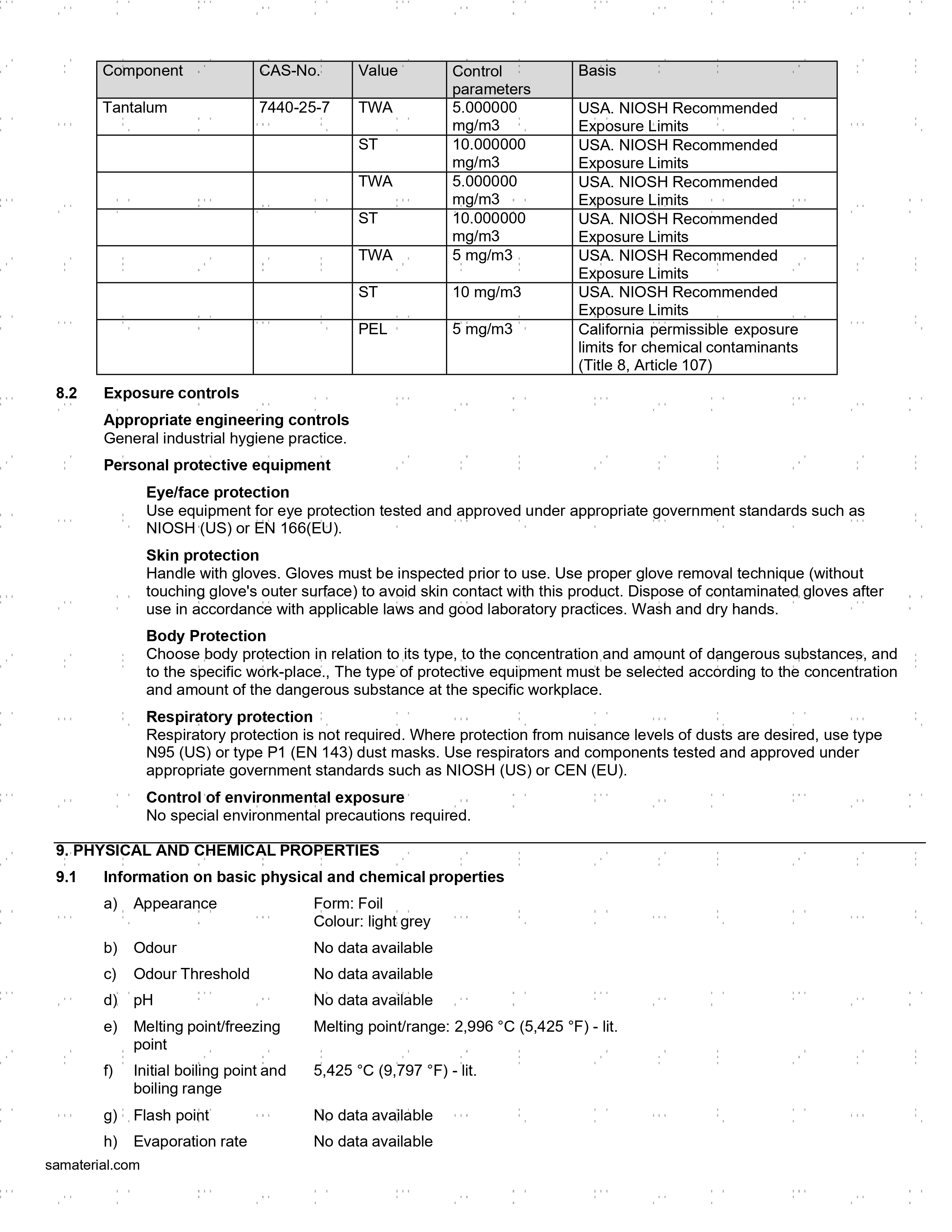

Material Safety Data Sheet (MSDS) for your reference!

Tantalum Sputtering Target FAQs

Can tantalum sputtering targets be bonded to a backing plate?

Yes, tantalum sputtering targets can be bonded to copper backing plates using indium or elastomer bonding methods.

Are there any special storage or handling requirements for tantalum sputtering targets?

Tantalum sputtering targets should be stored in a clean, dry environment to prevent surface contamination.

What is the recommended sputtering method for tantalum targets?

DC magnetron sputtering is the most commonly used method for depositing tantalum films.