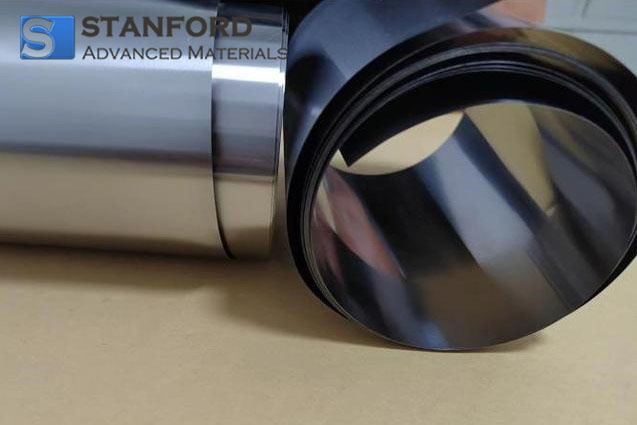

Tantalum Capillary Description

Tantalum Capillary tubing is a high-quality material with many outstanding properties. It has a high melting point and high hardness, enabling it to remain stable at very high temperatures and pressures, as well as a low coefficient of thermal expansion, ensuring dimensional stability. Tantalum Capillaries also have excellent corrosion resistance and good electrical properties, allowing them to excel in a variety of chemical and industrial applications. In addition, the biocompatibility of Tantalum Capillaries makes them widely used in medical implants and other biomedical applications. These properties make Tantalum Capillary tubes ideal for use in aerospace, electronics, petrochemical and medical applications, and we are committed to providing the highest quality Tantalum Capillary tubes to meet the needs of a variety of applications.

Tantalum Capillary Specification

| Outer Diameter (OD) |

0.2~8mm |

| Wall Thickness (WT) |

0.015 ~ 1mm |

| Length (L) |

1mm~1000mm |

| Tolerance |

OD, +/-0.003mm. WT, +/-0.005mm. L, +/-0.05mm |

If you require larger sizes, you can see tantalum tube

Tantalum Capillary Chemical Composition

|

Element

|

R05200 (%,Max)

|

R05400 (%,Max)

|

|

C

|

0.01

|

0.01

|

|

O

|

0.015

|

0.03

|

|

N

|

0.01

|

0.01

|

|

H

|

0.0015

|

0.0015

|

|

Fe

|

0.01

|

0.01

|

|

Mo

|

0.02

|

0.02

|

|

Nb

|

0.1

|

0.1

|

|

Ni

|

0.01

|

0.01

|

|

Si

|

0.005

|

0.005

|

|

Ti

|

0.01

|

0.01

|

|

W

|

0.05

|

0.05

|

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace or vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, tantalum alloy, 60 % tantalum, 40 % nobium, electron-beam furnace or vacuum-arc melt.

Tantalum Capillary Application

1. Electronics industry: Due to its high melting point, low vapour pressure and good electrical properties, Tantalum Capillaries play an important role in electronic equipment. They are used in the manufacture of electronic components, connecting lines for integrated circuits, high-precision electronic tubes and so on.

2. Aerospace industry: In the aerospace sector, Tantalum Capillaries are favoured for their high strength, low density and high-temperature stability. They are used to manufacture structural components for aircraft and rockets, furnace tubes and crucibles for high-temperature furnaces, etc.

3. Medical: The biocompatibility and corrosion resistance of Tantalum Capillary tubes make them ideal for use in medical implants. It can be used to manufacture artificial joints, dental implants, cardiovascular equipment and other biomedical devices.

4. Chemical and petroleum industries: Tantalum Capillary tubing has excellent corrosion resistance, making it widely used in equipment such as chemical reaction vessels, pipes, valves and pumps. In the oil industry, it is used to manufacture oil drilling equipment and pipework.

5. Military industry: The hardness and wear resistance of Tantalum Capillary tubes make them used in the military field for the manufacture of arms, ammunition and weapon parts.

6. Other fields: In addition to the above applications, Tantalum Capillary tubes are also used to manufacture furnace tubes for high-temperature furnaces, thermocouple protection tubes, metalworking tools and so on.

Tantalum Capillary Packaging

Tantalum capillaries are carefully handled to prevent damage during storage and transportation.

Material Safety Data Sheet (MSDS) for your reference!

FAQs

Q1: What are Titanium Fittings used for?

A1: Titanium fittings are widely used in industries where high strength, low weight, and excellent corrosion resistance are required, including:

Aerospace and aviation – for structural components and fluid systems

Chemical and petrochemical industries – pipes, valves, and fittings exposed to aggressive chemicals

Medical devices – for implants and surgical tools due to titanium's biocompatibility

Marine environments – for seawater handling systems

Power generation – in heat exchangers and other high-performance equipment

Q2: What are the key properties of Titanium Fittings?

A2: Corrosion resistance – titanium is highly resistant to corrosion in harsh environments, including seawater and acids

High strength-to-weight ratio – titanium is lightweight yet extremely strong

Biocompatibility – safe for medical applications and body implants

High temperature resistance – ideal for use in high-temperature environments

Non-magnetic properties – useful for applications in sensitive environments, such as electronics and MRI machines

Q3: What types of Titanium Fittings are available?

A3: We offer a wide range of titanium fittings, including:

Elbows

Tees

Flanges

Reducers

Adapters

Couplings

Custom fittings tailored to specific requirements

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano.jpg)

.jpg)