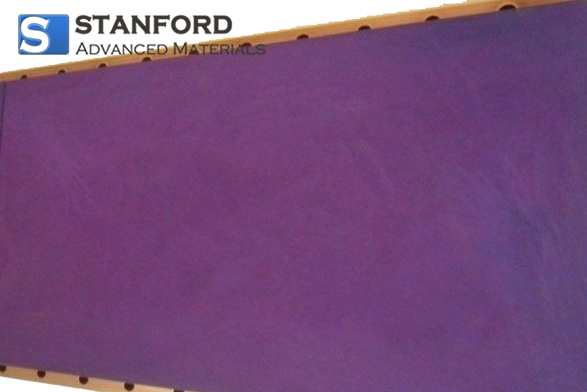

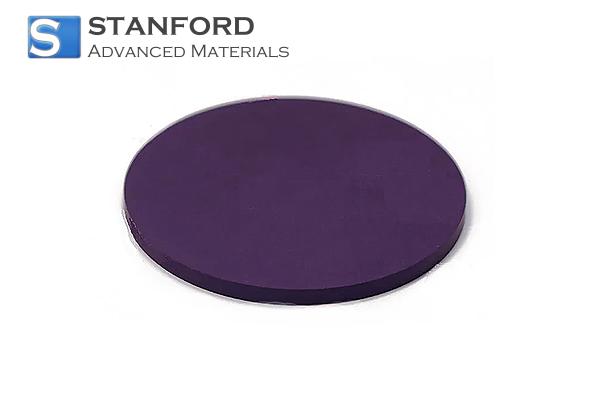

Cerium Hexaboride Disc Description

Cerium Hexaboride Disc undergoes a meticulous fabrication process, primarily sintering, wherein powdered cerium hexaboride is compressed and heated. This yields a dense, solid ceramic structure that preserves the advantageous properties of cerium hexaboride. Tailored for technological applications demanding high-performance electron emission, this ceramic part excels in delivering reliable and efficient electron beams. Renowned for its high brightness, it significantly enhances the intensity of the produced electron beam—a crucial factor for achieving superior resolution in electron microscopy.

Cerium Hexaboride Disc Specification

|

Parameter

|

Units

|

CeB6

|

|

Stoichiometry

|

N/A

|

~6

|

|

Metal Impurities

|

Ppm by wt.

|

<30

|

|

Density

|

g/cm3

|

4.80

|

|

Coefficient of Thermal Expansion

|

α*106

|

6.2

|

|

Electrical Resistivity

|

μΩ-cm

|

~65

|

|

Effective Work Function(100) at 1800K

|

eV

|

2.65

|

|

Spectral Emissivity at 0.65 Microns

|

N/A

|

0.779

|

|

Evaporation Rate at 1800K(UHV)

|

g

|

1.6×10-9

|

|

Orientation Limit for a Specific Orientation

|

Degrees

|

<2

|

|

Pyrolitic Block Mount Resistance at 1800K

|

Ohms

|

1.45

|

Prototyping service also available for other ceramics material

Alumina

Aluminum Nitride

Boron Nitride

Silicon Carbide

Silicon Nitride

Zirconia

Cerium Hexaboride Disc Applications

1. Thermionic Cathodes: CeB6 discs are often used as thermionic cathodes in electron guns, especially in electron microscopes, X-ray tubes, and particle accelerators. Their stable and efficient electron emission makes them ideal for generating a consistent electron beam.

2. Vacuum Electronic Devices: In devices like traveling wave tubes (TWTs) and klystrons, which are used in telecommunications and radar systems, CeB6 discs serve as a source of electrons due to their high emission efficiency.

3. Ion Thrusters: Similar to other CeB6 components, discs are used in ion propulsion systems for spacecraft. Their role is crucial in producing the ionized plasma required for propulsion, thanks to their ability to emit electrons at high temperatures.

4. Surface Science Research: CeB6 discs are used in research settings, particularly in surface science studies where their properties are tested under high-temperature and vacuum conditions. This helps in understanding materials' behavior at the atomic level.

5. Field Emission Displays (FEDs): CeB6 discs can be used as electron emitters in field emission displays, a technology considered for high-efficiency and high-brightness displays.

6. Calibration and Reference Sources: Due to their stable emission properties, CeB6 discs can be used as standard electron sources in calibration equipment for various scientific instruments.

7. High-Temperature Electronics: In certain high-temperature electronic applications, CeB6 discs can be used as components where reliable electron emission is required under extreme conditions.

Cerium Hexaboride Disc Packing

Cerium Hexaboride Disc is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Cerium Hexaboride Disc FAQs

Q1: What is a Cerium Hexaboride Disc?

Answer: A Cerium Hexaboride (CeB₆) disc is a circular piece made from cerium hexaboride, known for its exceptional electron emission properties, high melting point, and chemical stability. These discs are used in various high-tech applications.

Q2: Why is Cerium Hexaboride preferred for electron emission applications?

Answer: CeB₆ is preferred because of its low work function, high electron emission efficiency, and stability at high temperatures, which make it ideal for generating consistent electron beams in high-vacuum conditions.

Q3: How are Cerium Hexaboride Discs manufactured?

Answer: CeB₆ discs are typically manufactured using powder metallurgy techniques, which involve pressing CeB₆ powder into a disc shape and then sintering it at high temperatures to achieve the desired density and mechanical properties.