- Products

- Categories

- Blog

- Podcast

- Application

- Document

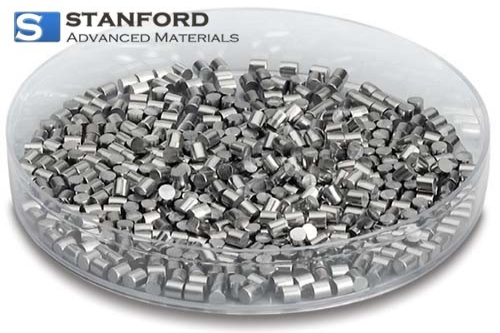

LM1777 Aluminum Lithium (Al-Li) Alloy Weldalite 049

| Catalog No. | LM1777 |

| Surface | Polished |

| Thickness | 1-20 mm |

| Width | 100-450 mm |

| Diameter | φ80-φ200 |

Aluminum Lithium (Al-Li) Alloy Weldalite 049 is generally joined by friction stir welding. Stanford Advanced Material provides standard and customized size Aluminum-Lithium alloy rolled plate/ingot. Our aluminum-lithium (Al-Li) alloy weldalite 049 has reached the standard for supply to the institute of the military.

Related Products: Aluminum Lithium (Al-Li) Alloy 8090, Aluminum Lithium (Al-Li) Alloy Rolled Plate/Ingots, Aluminum Lithium (Al-Li) Alloy 1420

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!