Micro Tungsten Carbide Powder (Micro WC Powder) Description

Tungsten Carbide Powder is meticulously crafted using a precise production process, ensuring exceptional purity and consistency. This high-performance powder boasts remarkable hardness, durability, and wear resistance, making it ideal for manufacturing cutting tools, dies, and various wear-resistant parts. Its excellent thermal and electrical conductivity properties further enhance its versatility, ensuring optimal performance across diverse industries such as automotive, aerospace, and mining.

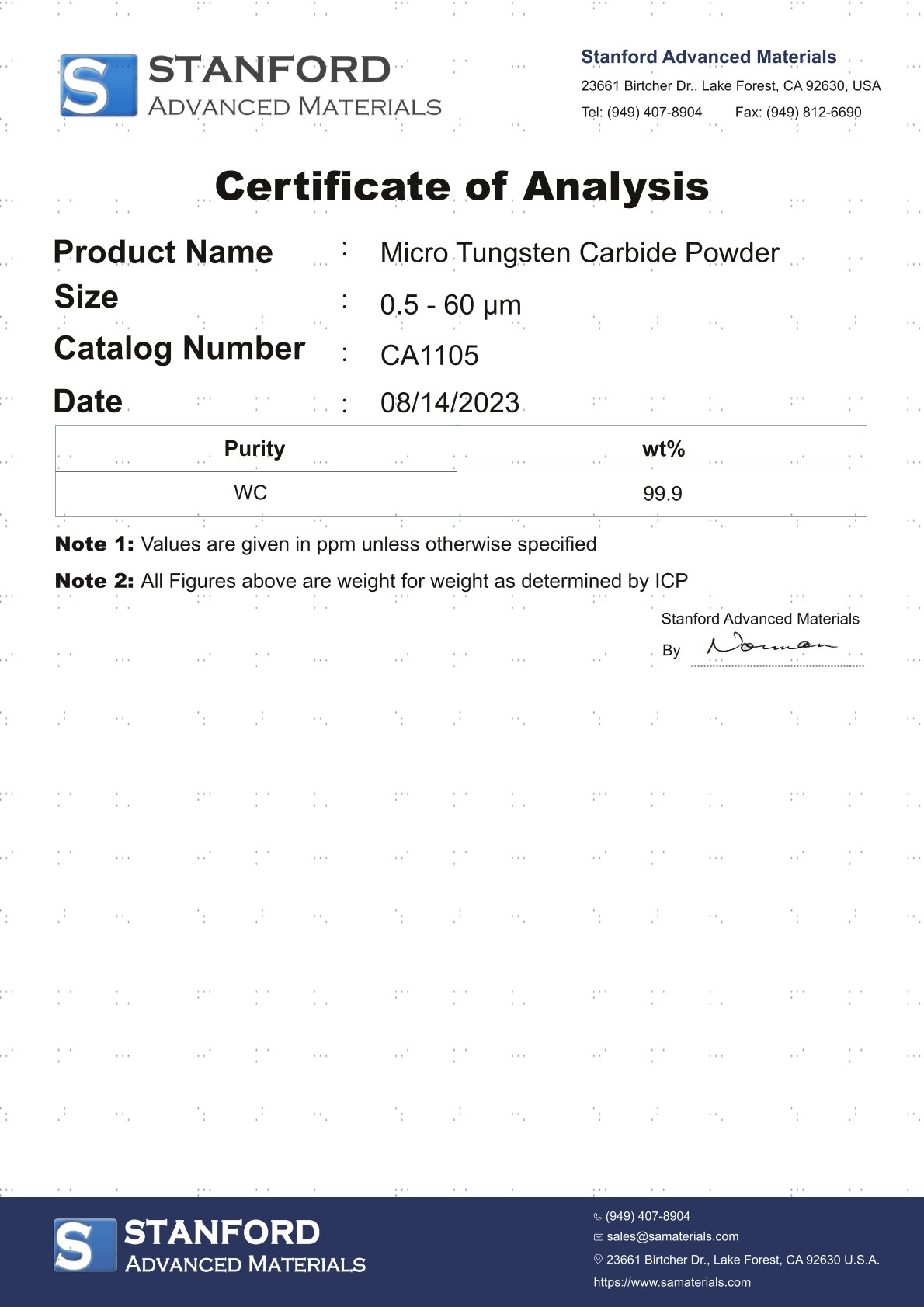

Micro Tungsten Carbide Powder (Micro WC Powder) Specifications

|

Chemical Formula

|

WC

|

|

CAS No.

|

12070-12-1

|

|

Particle Size (μm)

|

0.5 to 60

|

|

Melting Point

|

2870℃

|

|

Purity

|

99.9%

|

|

Morphology

|

Hexagonal

|

Chemical Composition

|

Particle Size (μm)

|

Chemical Composition (%)

|

|

Oxygen

|

Total C

|

Free C

|

Combined C

|

Fe

|

Mo

|

|

0.9-1.1

|

0.15

|

6.15±0.05

|

0.06

|

6.07

|

≦0.020

|

≦0.010

|

|

1.2-1.4

|

0.12

|

6.13±0.05

|

0.06

|

6.07

|

≦0.020

|

≦0.010

|

|

1.4-1.6

|

0.10

|

6.13±0.05

|

0.05

|

6.08

|

≦0.020

|

≦0.010

|

|

1.8-3.2

|

0.07

|

6.13±0.05

|

0.05

|

6.08

|

≦0.020

|

≦0.010

|

|

3.3-6.0

|

0.05

|

6.13±0.05

|

0.05

|

6.08

|

≦0.020

|

≦0.010

|

|

6.0-7.5

|

0.04

|

6.13±0.05

|

0.05

|

6.08

|

≦0.020

|

≦0.010

|

|

7.5-10

|

0.03

|

6.13±0.05

|

0.05

|

6.08

|

≦0.020

|

≦0.010

|

Micro Tungsten Carbide Powder (Micro WC Powder) Applications

1. Cutting tools: Tungsten Carbide Powder is widely used in the production of cutting tools such as drills, saw blades, milling cutters, and turning tools. It offers excellent hardness, wear resistance, and high-temperature stability, making it ideal for cutting and machining applications.

2. Mining and drilling: Tungsten Carbide Powder is used to manufacture drilling bits, inserts, and other wear-resistant components for mining and drilling operations. Its hardness and resistance to abrasion make it suitable for drilling rock, concrete, and other tough materials.

3. Metalworking: Tungsten Carbide Powder is used in the production of metalworking tools, such as dies, punches, and forming tools. It enables high-speed machining, improves precision, and prolongs tool life.

4. Wear parts: Tungsten Carbide Powder is used to produce wear-resistant components, such as nozzles, valves, bearings, and seals, that are exposed to abrasive or erosive environments. It provides long-lasting performance and reduces maintenance costs.

5. Aerospace and defense: Tungsten Carbide Powder finds applications in aerospace and defense industries, primarily in the manufacturing of turbine components, armor-piercing ammunition, and missile parts. It offers excellent strength, hardness, and heat resistance needed for such demanding applications.

6. Automotive industry: Tungsten Carbide Powder is used in the production of wear-resistant parts for engines, transmissions, brakes, and suspension systems in the automotive industry. It helps improve performance, reduce friction, and increase component lifespan.

7. Medical and dental tools: Tungsten Carbide Powder is utilized in the production of medical and dental instruments like surgical instruments, orthodontic brackets, and dental drills. It provides the precision and durability required for these applications.

8. Electronics: Tungsten Carbide Powder is used in the production of electronic components, such as electrical contacts, heat sinks, and circuit board-mounted components. It offers good electrical conductivity, thermal stability, and mechanical strength.

9. Energy industry: Tungsten Carbide Powder finds applications in the energy sector, including oil and gas drilling tools, wear-resistant parts for power generation equipment, and components used in renewable energy systems like wind turbines.

Micro Tungsten Carbide Powder (Micro WC Powder) Packaging

Our Micro Tungsten Carbide Powder (Micro WC Powder) is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

![sc/1686725386-normal-[Robert] CA1105.jpg](https://7cad390533514c32acc8-75d23ce06fcfaf780446d85d50c33f7b.ssl.cf6.rackcdn.com/sc/1686725386-normal-[Robert] CA1105.jpg)